Showing all 89 results

Featured products

-

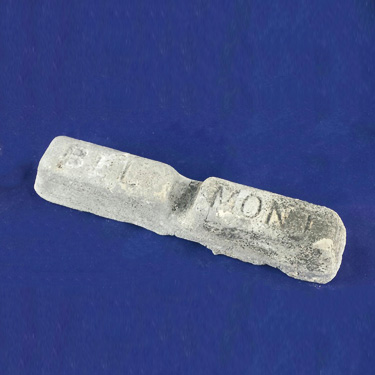

Forms: - 5-6 Ingot

- 1/4" and Down Unpolished Irregular Shot

- .05" Dia. Solid Wire 1 Lb. Spools

Belmont Product Code 7921 Nominal Composition: - 91.75% Sn

- 8% Sb

- 0.25% Cu

Technical Info: - Elongation (2" Section) : 20% - 40%

- Liquidus Temperature: 465F - 485F

- Solidus Temperature: 515F - 635F

- Density: .23 - .275 lb. / Cu. In. @ 68F

- Brinell: 18 - 25

- Tensile Strength: 5,000 psi - 8700 psi

- Solderability: Can be soldered Easily with soft solder and flux

- Finishes: Mechanical, chemical, organic, and electroplated

-

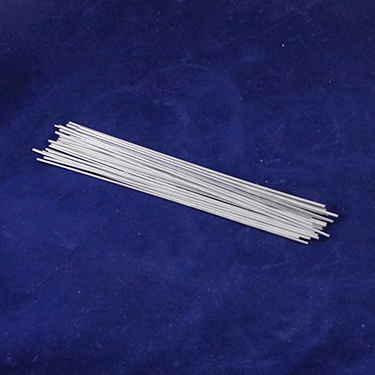

This Solder has good corrosion resistance and tensile strength. With a melting range beginning at 390 Deg. F. it avoids causing damage to critical electronics as well preventing substrate deformation and segregation. It is used very often in spray wire form for capacitors and other electronic parts. Forms: - 1/16" Dia. Plus .000" Minus .004" on 5 Lb. Spools

- 2-5 Ingot

- Cast Flat Anodes

Belmont Product Code 7601DS1C Nominal Composition: - 60.5% Sn

- 39.5% Zn

-

A Copper (Cu) Alloy containing Chromium (Cr) used for their high strength and corrosion resistance. It offers high conductivity, good ductivity and strength. Serves as a master alloy to add chrome to various copper alloys. Forms: - 2-20 Ingot

Belmont Product Code 4989 Nominal Composition: - 98.7% Cu

- 1.3% Cr

Technical Info: - CDA #: 81500

- Melting Point (Liquidus): 1985 F, 1085 C

- Melting Point (Solidus): 1967 F, 1075 C

- Density: .319 lb./cu. in. @ 68 F

- Specific Gravity: 8.82

- Thermal Conductivity: 182 Btu./sq. ft./ft./hr/F @ 68 F

- Tensile Strength-ksi: 51

-

Chrome is an addition generally made in Copper Alloys for corrosion resistance and electrical conductivity. Forms: - 2-10 Ingot

Belmont Product Code 4906 Nominal Composition: - 90% Cu

- 10% Cr

-

Lithium added to Alloys containing Magnesium help prevent dross formation. Forms: - 1" x 6" X 12" Slabs

- 2-2 Ingot

Belmont Product Code 19515 Nominal Composition: - 95% Al

- 5% Li

-

-

Forms: - 3-16 Ingot

Belmont Product Code 18912 Nominal Composition: - 90% Al

- 2% Cu

- 0.8% Mg

- 1.2% Ni

- 6% Sn

-

319 has excellent casting and machining characteristics. Corrosion resistance and weldability are very good and the mechanical properties are good. The anodized color is generally gray with a brown cast depending on the amount and ratio of silicon and copper. Typical applications for sand casting 319.0 are a wide variety of structural castings for engine parts, gas and oil pans, and general commercial applications. Forms: - 22 Lb. Ingot

Belmont Product Code 10319 Nominal Composition: - 90.5% Al

- 3.5% Cu

- 6% Si

-

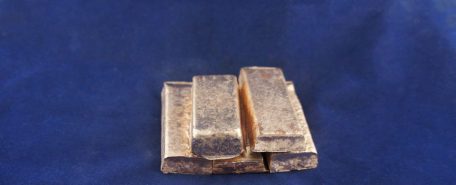

35% Tin Pewter, Lead, Tin Alloy easy meltable with relatively low melting temperature. Offers opportunity for cost savings where its relatively high weight is not a problem . Offers opportunity for cost savings where its relatively high weight is not a problem. Forms: - 5-8 Ingot

Belmont Product Code 5632 Nominal Composition: - 62% Pb

- 3% Sb

- 35% Sn

-

-

A380 offers the best combination of casting, mechanical, and thermal properties and exhibits excellent fluidity, pressure tightness, and resistance to hot cracking. It is used for a wide variety of products including chassis for electronic equipment, engine brackets, gearbox cases, household furniture, power, and hand tools. Forms: - 3-16 Ingot

Belmont Product Code 18810 Nominal Composition: - 88% Al

- 3.5% Cu

- 8.5% Si

-

-

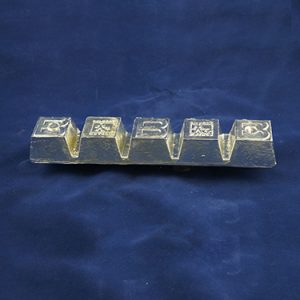

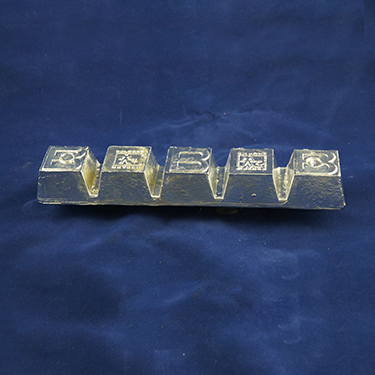

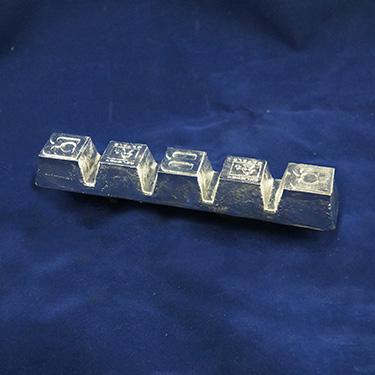

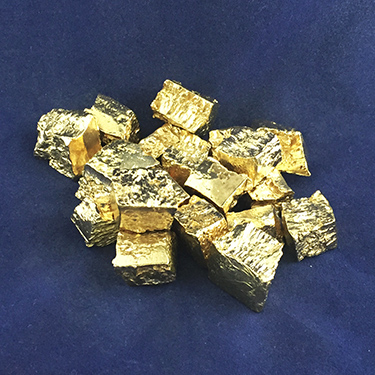

Bell metal is a hard alloy used for making bells and related instruments, such as cymbals. It is a form of bronze with a higher tin content, usually in approximately a 4:1 ratio of copper to tin (typically, 78% copper, 22% tin by mass). We offer this material in Ingot, shot, and cut pieces. Forms: - Ingot

- Irregular Shot

- 1/2" Polished Cubes

- 2" Cut Pieces

Belmont Product Code 4788 Nominal Composition: - Cu: 78%

- Sn: 22%

-

This alloy offers high strength, hardness, wear resistance with excellent fluidity. This alloy is ideal for investment, sand or ceramic casting and provides excellent replication of intricate detail. Forms: - 2-5 Ingot

- 2" Cut Bars

- 1" Cut Bar

- 1/2" Polished Cubes

- 1/2" x 14 Mesh Shot

Belmont Product Code 4977 Nominal Composition: - 97.2% Cu, 2.05% Be, 0.5% Co, 0.25% Si

-

Copper-Nickel 70/30 excellent resistance to corrosion and erosion. It's strong and dectile and is utilized in areas where high temperatures and pressures, combined with high velocities and turbulence are serious problems. Forms: - 2-20 Ingot

Belmont Product Code 47025 Nominal Composition: - 66% Cu

- 30.9% Ni

- 0.4% Si

- 1% Mn

- 0.7% Fe

- 1% Cb

Technical Info: - CDA #: 96400

-

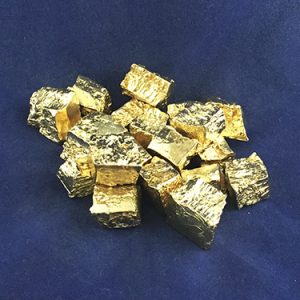

This material offers the highest strength and hardness of all the BeCu alloys with excellent wear resistance and fluidity. Also offers extremely fine detail pick-up in ceramic or pressure cast processes. This also has the lowest pouring temperature of the BeCu alloys allowing almost any type of molding process to be used. Forms: - 1/2" and Down Polished Shot

- 1/2" X 14 Mesh Unpolished Shot

- 2-5 Ingot

Belmont Product Code 4971 Nominal Composition: - 96.43% Cu

- 2.7% Be

- 0.5% Co

- 0.3% Si

- 0.07% Ti

-

-

A357 is typically used in situations where high strength combined with high corrosion resistance and/or pressure tightness are required. A357 is commonly used to make parts; including structural, machine, impellers, housings, pump and valve components, tools, frames, and brackets. Forms: - 30 lb Ingot

Belmont Product Code 19320 Nominal Composition: - 92.2%Al

- 7% Si

- 0.6% Mg

- Bal

-

Copper-Nickel 90/10 has a very good resistance to uniform and local corrosion in seawater and, as opposed to other copper alloys, is not as susceptible to stress corrosion cracking. Forms: - 2-20 Ingot

Belmont Product Code 49019 Nominal Composition: - 86.85% Cu

- 10% Ni

- 1% Mn

- 1.4% Fe

- 0.75% Cb

Technical Info: - CDA #: 96200

-

Slush Cast alloy is a high purpose-engineered product. This alloy was developed to provide a high fluidity casting material capable of producing a good surface definition when cast in metal permanent molds or rubber molds. It contains approximately 5% Aluminum and 95% Zinc. It is used primarily for the use of hollow castings. Forms: - 4-20 Ingot

Belmont Product Code 8952 Nominal Composition: - 95% Zn

- 5% Al

-

Zinc/Aluminum solder 99% Zinc and 1% Aluminum. Used by the Romans and is commonly used today, particularly in musical instruments and many hardware applications that must resist corrosion. Zinc is an alloy with Lead and Tin to make solder, a metal with a relatively low melting point used to join electrical components, pipes and other applications. Forms: - 4-20 Ingot

Belmont Product Code 8995 Nominal Composition: - 99% Zn

- 1% Al

-

The 200-Series of Aluminum-Copper Alloys are well known for very high strength; nearly double that of the more common 300-Series of Aluminum-Silicon alloys. However, the 200 series can be very difficult to cast. These alloys should be considered where the strength vs. weight ratio is the key consideration such as in the Aerospace and Transportation sector. Forms: - 3-16 Ingot

Belmont Product Code 19215 Nominal Composition: - 92.35% Al

- 5% Cu

- 1.5% Ni

- Bal

-

This is our Original, Lead Free, Zinc Based Alloy that works well in Spin Cast Vulcanized Silicone Molds for designs with thick cross sections or minimal detail. Contains Proprietary Grain Refiners for improved casting properties. Forms: - 4-20 lb. KZ Ingot

Belmont Product Code 892NS1 Nominal Composition: - 90-94% Zinc in a Proprietary Formula

Technical Info: - Elongation : 8%

- Liquidus Temperature: 734F

- Pouring Temperatire: 800 F - 875 F

- Density: .244 lbs / Cu. In.

- Tensile Strength: 54,000

- Compression Strength: 68,800 psi

- Brinell Hardness: 146

- Finishes: Mechanical, chemical, organic, and electro-deposited, plastic

-

-

-

-

Aluminum Bronze 415A Alloy CDA# 952 "Chemistry ONLY". Aluminum bronze bearings are used in heavy loaded applications. Forms: - 2-20 Ingot

Belmont Product Code 4872 Nominal Composition: - 87.5% Cu

- 9% Al

- 3.5% Fe

Technical Info: - CDA #: 95200

-

This alloy exhibits good strength, coupled with excellent corrosion resistance and material toughness properties. This comparatively lower percentage Beryllium alloy provides thermal conductivity properties that are far superior to most Aluminum, Magnesium & Steel alloys. Forms: - 2" Cut Bars

- 2-20 Ingot

- 2-5 Ingot

Belmont Product Code 4972 Nominal Composition: - 96.8% Cu

- 0.65% Be

- 2.55% Co

-

This Beryllium Copper alloy provides good resistance to corrosion along with high strength and hardness. It is very suitable for salt water immersion applications and also offer excellent replication of intricate detail. Forms: - 2" Cut Bars

- 2-5 Ingot

Belmont Product Code 4986 Nominal Composition: - 98% Cu

- 1.7% Be

- 0.3% Co

-

With the highest Copper content of all BeCu alloys this alloy offers superior strength and hardness along with superior thermal conductivity. It is recommended for Investment, continuous and centrifugal casting methods. Forms: - 2-5 Ingot

Belmont Product Code 4992 Nominal Composition: - 99.12% Cu

- 0.08% Be

- 0.8% Cr

-

Leaded red brass is typically found in plumbing applications. It is known for its reasonable cost with good machining and casting properties. The lead content ensures pressure tightness. Red brass is also used for low-cost bearing materials under low loads. Forms: - 1" x 6" x 12" Slabs

- 2-20 Ingot

- 2" Sheared Pcs.

Belmont Product Code 4852 Nominal Composition: - 85% Cu

- 5% Zn

- 5% Sn

- 5% Pb

Technical Info: - CDA #: 83600

-

Lead,Tin, Antimony Alloy. Low Melting fusible alloy. Excellent low-cost alloy. High-antimony lead alloy specially treated to increase ductility and fluidity. Useful where casting may be subject to bending. Forms: - 2-8 Ingot

Belmont Product Code 5877 Nominal Composition: - 86.925% Pb

- 10% Sb

- 3% Sn

- 0.0725% Te

-

-

Forms: - Approx. 35 Lb. Ingots

Belmont Product Code 1920 Nominal Composition: - 92.22% Al

- 7% Si

- 0.6% Mg

- Bal

-

Commercial Zinc base alloy, it contains approximately 15% Aluminum and 85% Zinc. Specially formulated and metallurgically designed to provide superior casting results in Spin-Casting applications. Forms: - 4-16 Ingot

Belmont Product Code 8853 Nominal Composition: - 85% Zn

- 15% Al

-

Belmont MAB ( Miter-AL-Braze ) rod is an effective and efficient joining material. While not as hard and strong as our No. I Regular version this item was developed to provide extra ductility. MAB II Hi-Test has often been used by aluminum window manufacturers to join mitered corners, where some bending is required during installation. The strength of an MAB joint in many cases is as great as that of a brazed joint and this material is most commonly used for joining aluminum pieces. Forms: - 1/8” X 18” Cast Strip

- 3/32” X 18” Cast Strip

- Ingot

Belmont Product Code 8911 Nominal Composition: - Proprietary

-

Manganeze bronze is a high strength and a hard alloy containing manganese and zinc. It's used for highly stressed machine parts. Forms: - 1/2" Polished Cubes

- 2-20 Ingot

Belmont Product Code 4643 Nominal Composition: - 65% Cu

- 25% Zn

- 3% Mn

- 4% Al

- 3% Fe

Technical Info: - CDA #: 86200

-

Navy M Leaded Bronze C92200 Bronze is an alloy of copper, further classified as a bronze (copper-tin- alloy). Is used for a variety of steam pressure applications involving temperatures up to 550 F. Forms: - 1-20 Ingot

Belmont Product Code 4884 Nominal Composition: - 88% Cu

- 4% Zn

- 8% Sn

Technical Info: - CDA #: 90300

-

Navy M Leaded Bronze C92200 Bronze is an alloy of copper, further classified as a bronze (copper-tin- alloy). Is used for a variety of steam pressure applications involving temperatures up to 550 F. Forms: - 20 Lb. Ingots

Belmont Product Code 4888 Nominal Composition: - 88% Cu

- 4.5% Zn

- 6% Sn

- 1.5% Cr

Technical Info: - CDA #: 92200

-

Forms: - 2-20 Ingot

Belmont Product Code 4562 Nominal Composition: - 57% Cu

- 20% Zn

- 12% Ni

- 2% Sn

- 9% Pb

Technical Info: - CDA #: 97300

-

Belmont Special 92% Tin Pewter alloy is an excellent casting alloy with approximately 92% Tin (Tin base alloy). Special Pewter for figurines, models, etc. with heavy sections - better casting characteristics than lead free Britannia. Forms: - 5-6 Ingot

Belmont Product Code 7924 Nominal Composition: - 92% Sn

- 4% Pb

- 4% Sb

-

-

A Proprietary Tin Base Babbitt similar to ASTM B23 Grade 2 Babbitt with additions for added strength. Belmont Product Code F10 Nominal Composition: - Proprietary

-

A Prorietary Lead Base Babbitt for low speed applications. Belmont Product Code L2 Nominal Composition: - Proprietary

-

A Proprietary Lead Base Babbitt with high compression, strength, and excellent heat transfer. Belmont Product Code B3 Nominal Composition: - Proprietary

-

A Proprietary Lead Base in the manufacture of wood chipper knives. Belmont Product Code C3 Nominal Composition: - Proprietary

-

A Proprietary Lead Base Babbitt often used in the relining of bearings in elevators. Belmont Product Code P1 Nominal Composition: - Proprietary

-

A Proprietary Tin Base Lead Free Alloy with high tensile strength for heavy load applications. Belmont Product Code NV8 Nominal Composition: - Proprietary

-

A Proprietary Lead Base Alloy with a small addition of Nickel for additional hardness. Belmont Product Code J1 Nominal Composition: - Proprietary

-

-

A Proprietary Tin Base Alloy for medium load application. Belmont Product Code W1 Nominal Composition: - Proprietary

-

A Proprietary Tin Base Alloy used for high speed high load applications. Belmont Product Code D3 Nominal Composition: - Proprietary

-

A Proprietary Tin Base Babbitt Alloy with Nickel additions for added strength. Belmont Product Code E5 Nominal Composition: - Proprietary

-

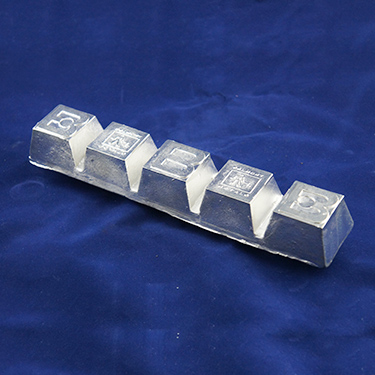

Zamak 12 offers high hardness and high tensille strenght. This is the preferred alloy for permanent mold applications although it can also be cold-chamber die-cast with excellent results. It combines low temperature melting efficiency and thin wall capabilities with premium mechanical properties. ZA-12 can usually be poured directly into molds designed for aluminum and brass. Forms: - 4-20 Ingot

Belmont Product Code 8871 Nominal Composition: - 88% Zn

- 11% Al

- 1% Cu

-

Zamak 3 is a family of alloys with a base metal of zinc and alloying elements of aluminum, magnesium and copper. It is the most commonly used in Zinc die casting, providing an excellent combination of strenght, ductility. It also provides excellent plating and finishing characteristics. This alloy is the designers first choice for die casting applications and the most widely used in North America. Forms: - 4-20 Lb. Ingot

Belmont Product Code 8961 Nominal Composition: - 96% Zn

- 4% Al

-

Zamak 7 is a modification of Zamak 3. However, Zamak 7 has higher ductility (for Forming and bending operations) and the highest casting fluidity of the Zamak family. Excibits excellent damping capacity and vibration attenuation in comparison with aluminum die casting alloys. Forms: - 4-20 Ingot

Belmont Product Code 8962 Nominal Composition: - 95.87% Zn

- 4.1% Al

- 0.015% Mg

- 0.015% Ni