Jewelry casters are always on the lookout for metals and alloys that offer good castability, beauty, and economical prices to create sculptures, rings, earrings, necklaces, bracelets, and other fine jewelry. One jewelry that has a goldfish color is Everdur Silicon Bronze. This alloy provides a wide range of benefits for castings. What is Everdur Silicon…

Featuring Silicon Bronze Everdur, Silicon Bronze, Special H Silicon Brass, Art Casters Brass, White Bronze, and many other different Brass alloys meeting CDA specifications

Brass is an alloy containing Zinc as the principal alloying element with or without other designated alloys such as Tin, Aluminum, Nickel, and Lead . By Comparison Bronze is principally an alloy of Copper and Tin. Bronze does not necessarily contain Tin, and a variety of alloys of Copper, including alloys with Iron, Phosphorus, Lead, Aluminum, Manganese, and Silicon are commonly termed Bronze. It is hard and tough, and it was so significant in antiquity that the Bronze Age was named after the metal.

Applications:

Brass is used for decoration for its bright gold-like appearance; for applications where low friction is required such as locks, gears, bearings, doorknobs, ammunition casing and valves. It is also used for plumbing and electrical applications; and extensively in brass musical instruments such as horns and bells for its acoustic properties.

Bronze is the most popular metal for cast metal sculptures. Bronze alloys have the unusual and desirable property of expanding slightly just before they set, thus filling the finest details of the mold. Then as the bronze cools, it shrinks a little making it easier to separate from the mold.

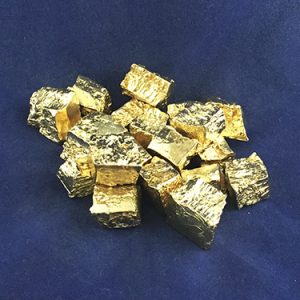

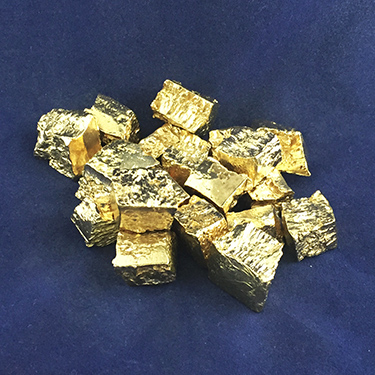

Forms: 20 Lb. Ingot, 5 Lb. ingot, Shot ( Polished or Unpolished ), 1/2” Polished Cubes, 2” Cut Bars

Read More

Showing all 24 results

Featured products

-

Easily cast White Brass Alloy with good fluidity and high detail. We offer this material in a variety of forms including Ingot, Cut Bars, Cubes and Shot. Forms: - Ingot

- 2" Cut Bar

- 1/2" Polished Cubes

- Shot

Belmont Product Code 45815 Nominal Composition: - Cu: 58%

- Mn: 20%

- Zn: 20%

- Al: 1%

- Pb: 1%

-

Bell metal is a hard alloy used for making bells and related instruments, such as cymbals. It is a form of bronze with a higher tin content, usually in approximately a 4:1 ratio of copper to tin (typically, 78% copper, 22% tin by mass). We offer this material in Ingot, shot, and cut pieces. Forms: - Ingot

- Irregular Shot

- 1/2" Polished Cubes

- 2" Cut Pieces

Belmont Product Code 4788 Nominal Composition: - Cu: 78%

- Sn: 22%

-

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - 1" x 1" x 1" Nuggets

- Cast Flat Top Anode Approx 1-1/4" Each

Belmont Product Code 47018A Nominal Composition: - 30% Zn

- 70% Cu

Technical Info: - CDA #: 96400

-

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - Cast Flat Top Anode Approx 1-1/4" Each

- 1" x 1" x 1" Nuggets

Belmont Product Code 48012A Nominal Composition: - 20% Zn

- 80% Cu

Technical Info: - CDA #: 87300

-

Leaded red brass is typically found in plumbing applications. It is known for its reasonable cost with good machining and casting properties. The lead content ensures pressure tightness. Red brass is also used for low-cost bearing materials under low loads. Forms: - 1" x 6" x 12" Slabs

- 2-20 Ingot

- 2" Sheared Pcs.

Belmont Product Code 4852 Nominal Composition: - 85% Cu

- 5% Zn

- 5% Sn

- 5% Pb

Technical Info: - CDA #: 83600

-

Navy M Leaded Bronze C92200 Bronze is an alloy of copper, further classified as a bronze (copper-tin- alloy). Is used for a variety of steam pressure applications involving temperatures up to 550 F. Forms: - 1-20 Ingot

Belmont Product Code 4884 Nominal Composition: - 88% Cu

- 4% Zn

- 8% Sn

Technical Info: - CDA #: 90300

RELATED POSTS

Benefits of Adding Silicon to Brass & Bronze Alloys for Certain

When certain materials are added to copper it changes the physical and mechanical composition of the metal. Two such materials are tin and zinc. Copper that has tin added into it is considered bronze. Bronze alloys provide a very hard metal that can sometimes be brittle and inflexible. When zinc is added to copper, it…

Art Casting: White Bronze vs. White Brass

Brass and bronze has long been used in the art casting and jewelry manufacturing industries. Brass alloys have excellent fluidity and malleability, while bronze alloys are very hard and brittle with low melting points. While we often think of these alloys as having colors ranging from brown to gold or red, there are also white…

Shot and Cubed Alloys: Advantages of Using Different Shaped Metals

Due to advanced manufacturing processes, companies today can use a range of base metals and alloys to create the right products and components to their industries. When obtaining the metals that will be used in casting, extruding and forming processes, manufacturers can request the alloys and base metals in various sizes and shapes. Ingots, cubes,…

The Use of White Bronze VS Pewter for Art Casting Applications

When it comes to casting applications, do you know which is better, white bronze or pewter? The most popular choice today and in the past has been pewter, but the use of white bronze has increased in recent years. Here at Belmont Metals, we have both white bronze and pewter that’s perfect for all your…

The Difference Silicon Bronze and Silicon Brass for Art Casting Applications

Craftspeople have been casting with bronze for so long that the BBC called it the “first alloy.” Introduced around 3,500 BC and typically made with mostly copper and tin, items made with bronze offered a more durable alternative to coper alone. Artifacts from brass have been dated to 500 BC. Brass may have been favored…

Brass and Bronze: Popular Use in Home Hardware Applications

Craftsman of home cabinetry, doors, windows and other features require hardware finishings to add functionality and beauty to the room. Home hardware consists of a wide range of applications, including door knockers, knobs, handles, hinges, cabinet pulls, and even air register covers. These items are typically made of a solid metal such as brass and…

Art Casting with Bronze and Brass

Creating art using the casting process dates back thousands of years as the oldest surviving piece of cast art dates back to 3200 BC. Yet artists today still enjoy creating a range of decorations, statues, figurines, jewelry and other artistic pieces using this process. The procedure involves using molten metals that are poured into a…

Brass and Bronze for Casting Alloys in Decorative Applications

When talking about brass and bronze, we most often think about these alloys in industrial settings, such as bronze industrial bushings and bearings, or brass valves and plumbing fixtures. Yet walk into a museum and will be surrounded by sculptures made out of bronze, or attend a classical opera and you will see brass instruments….

Choosing an Alloy to Get the Best Application Results

Brass and bronze are used in a range of applications, such as component parts for factories, end products for commercial retailers, and creating jewelry for the public. Brass alloys consist of the base metal of copper with varying amounts of zinc added, while bronze contains copper with aluminum, tin, magnesium and other materials. Yet how…

Nickel in Alloys For Jewelry Makers: Looking for Safer Alternatives

No matter the latest fashion trends hitting the New York and Paris runways, every model will have one thing in common: the jewelry they wear. Jewelry manufacturing is a booming business as adults and children of all ages are looking for the right jewelry to wear for everyday activities, special occasions and to have as…

Bring out the best

Master alloys help copper shine Red metals have played an important role in many cultures, including those of the ancient Egyptians and Romans, who crafted tools, cookware, dishes, mirrors and razors out of copper. Modern uses for copper include electrical, heating/cooling applications, fluid handling and plumbing applications, as well as an increasing demand for the…