Ensure you get the most out of this red-metal alloy by understanding its unique properties With each new generation of electronics, laptops get slimmer and more powerful and cell phones have even greater capacities for the amount of apps, music, and streaming sports and television that consumers want to carry around with them. All these…

Featuring Beryllium Copper Alloys in a Variety of forms; 4% Beryllium Copper, Beryllium Copper Alloys: 20C, 10C, 70C, 165C, 275C and more

Beryllium Copper, also known as Beryllium Bronze or Spring Copper, is a copper alloy with 0.5-3% Beryllium and sometimes other elements. The alloy combines high strength with non-magnetic and non-sparking qualities. It is typically used in applications where it is important to have to have a combination of excellent formability, high fatigue strength, good hysteresis properties and creep resistance. Beryllium Copper is also used where the requirements are for an alloy requiring corrosion resistance and relatively high electrical conductivity, or nonmagnetic behavior, coupled with high strength.

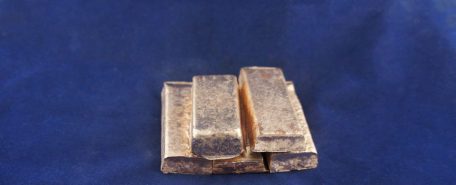

Beryllium Copper Alloy 20C, CDA 825, is our most popular offering in this category and contains 2% Beryllium, 0.5% Cobalt, and 0.25% Silicon. 20C Beryllium Copper (Belmont Product Code: 4977) is known for allowing excellent detail in your casting combined with high strength and an attractive color.

Forms: 2 Section 5 lb Ingot, Cut Bar – Cross Section ¾” x ½” x 1” lengths, 2”lengths, ½” polished cubes, polished and unpolished shot

Read More

Showing all 9 results

Featured products

-

A Beryllium containing copper base master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts. Forms: - Approx. 1" Pcs.

- 1/2" and Down Shot

- Slabs

Belmont Product Code 4962 Nominal Composition: - 96% Cu

- 4% Be

-

This alloy offers high strength, hardness, wear resistance with excellent fluidity. This alloy is ideal for investment, sand or ceramic casting and provides excellent replication of intricate detail. Forms: - 2-5 Ingot

- 2" Cut Bars

- 1" Cut Bar

- 1/2" Polished Cubes

- 1/2" x 14 Mesh Shot

Belmont Product Code 4977 Nominal Composition: - 97.2% Cu, 2.05% Be, 0.5% Co, 0.25% Si

-

This material offers the highest strength and hardness of all the BeCu alloys with excellent wear resistance and fluidity. Also offers extremely fine detail pick-up in ceramic or pressure cast processes. This also has the lowest pouring temperature of the BeCu alloys allowing almost any type of molding process to be used. Forms: - 1/2" and Down Polished Shot

- 1/2" X 14 Mesh Unpolished Shot

- 2-5 Ingot

Belmont Product Code 4971 Nominal Composition: - 96.43% Cu

- 2.7% Be

- 0.5% Co

- 0.3% Si

- 0.07% Ti

-

This alloy exhibits good strength, coupled with excellent corrosion resistance and material toughness properties. This comparatively lower percentage Beryllium alloy provides thermal conductivity properties that are far superior to most Aluminum, Magnesium & Steel alloys. Forms: - 2" Cut Bars

- 2-20 Ingot

- 2-5 Ingot

Belmont Product Code 4972 Nominal Composition: - 96.8% Cu

- 0.65% Be

- 2.55% Co

-

This Beryllium Copper alloy provides good resistance to corrosion along with high strength and hardness. It is very suitable for salt water immersion applications and also offer excellent replication of intricate detail. Forms: - 2" Cut Bars

- 2-5 Ingot

Belmont Product Code 4986 Nominal Composition: - 98% Cu

- 1.7% Be

- 0.3% Co

-

With the highest Copper content of all BeCu alloys this alloy offers superior strength and hardness along with superior thermal conductivity. It is recommended for Investment, continuous and centrifugal casting methods. Forms: - 2-5 Ingot

Belmont Product Code 4992 Nominal Composition: - 99.12% Cu

- 0.08% Be

- 0.8% Cr

RELATED POSTS

Bring out the best

Master alloys help copper shine Red metals have played an important role in many cultures, including those of the ancient Egyptians and Romans, who crafted tools, cookware, dishes, mirrors and razors out of copper. Modern uses for copper include electrical, heating/cooling applications, fluid handling and plumbing applications, as well as an increasing demand for the…

Controlling composition using Master Alloys

Create materials that meet specific needs by adding master alloys to the mix It’s important to choose the right materials for a job. Using inferior or unsuitable materials can make completing a project more difficult or even derail it entirely. In the metals industry, combinations of metals, called alloys, are generated to meet the specific…