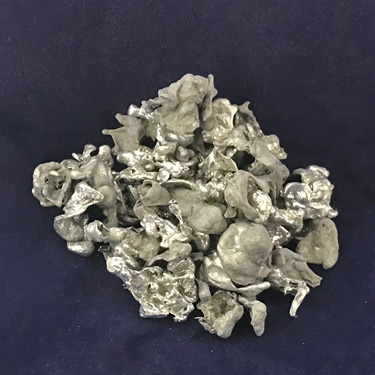

Zinc is a silvery white metal used throughout industrial manufacturing. This metal us used to create die casts that help create parts and components for a wide range of industries such as automotive, aerospace, and other industries. Another form or zinc, called zinc oxide, may be placed into paints, inks, plastics, pharmaceuticals, and even batteries. …

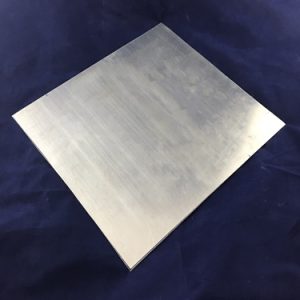

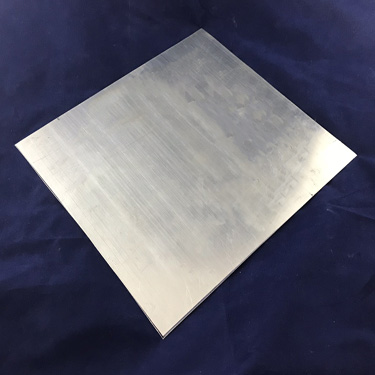

Featuring High Grade, Special High Grade, Mil Spec, MIL-A 1800L Zinc, and Zinc Sheet in a variety of forms

Centuries before it was identified as an element, zinc was used to make brass (an alloy of zinc and copper) and for medicinal purposes. Metallic zinc and zinc oxide were produced in India somewhere between the 11th and 14th centuries and in China in the 17th century, although the discovery of pure metallic zinc is credited to the German chemist Andreas Marggraf, who isolated the element in 1746. In modern times, Zinc is the 4th most widely consumed metal in the world after aluminum, iron, and copper.

The key property of Zinc, in its various uses, is the relatively slow and predictable rate of corrosion of Zinc compared to steel. As a result, Zinc’s most important uses is in galvanizing, the process of covering steel with a layer of Zinc for protection from corrosion. This is commonly used to protect roofing sheets, girders, nails, ladders, and buckets, and can be achieved by dipping the item in the molten metal or by electrolytic plating. Zinc and Zinc alloys are also used extensively to produce die-casting alloys where they compete fiercely with aluminum. Zinc sheet has many uses, including the cases for dry-cell batteries and the construction industry.

Read More

Showing all 10 results

Featured products

RELATED POSTS

Popular Applications and Uses for High Grade Virgin Zinc

Industries around the world rely on base metals and alloys in the manufacturing of parts, components, and complex assemblies that will be used in their operations or as products to consumers. One such metal is zinc. As the fourth most widely used metal in the world, zinc is a versatile and adaptable material that can…

The benefits of adding titanium to zinc alloys

Zinc in used in many applications from die casting to electroplating. However, zinc, by itself, is brittle and weak. For that reason, it’s often alloyed with other metals, including titanium. When zinc is alloyed with titanium, it becomes lightweight and exceptionally strong. Here at Belmont Metals, we offer zinc titanium alloys for manufacturing processes. Properties…

The benefits of adding aluminum to zinc alloys

Here at Belmont Metals, we offer zinc alloys, which are great for use in soldering applications, die casting and for use as a corrosion-resistant coating. Zinc is often alloyed with other types of metal in order to improve its strength and heat resistance. The Properties of Pure Forms of Zinc Pure forms of zinc are…

Sacrificial Anodes: Zinc Protecting Parts from Salt Water

Think about a corrosive substance that you deal with in your life. Most people will think about the rust on vehicles caused during the wintertime when road salt mixes with melting snow as it splashes onto the metal parts of their car. Now imagine dealing with saltwater on a daily basis when having maritime jobs…

Chemical reactions

ACS Reagent-grade Tin and Zinc for use in chemical analysis and compound creation Tin and Zinc are essential components of many alloys, but uses for these two elements extend beyond solders, die castings, galvanizing, and plating. Reagent grades of Zinc and Tin can be used in chemical analysis or other reactions. In organic chemistry, reagents…