For the last several months, metal markets have remained tough to predict because of the pandemic’s various impacts on demand and supply and the overall economic climate. Still, prudent businesses must base forecasts upon the best information they have available. Take a look at this year’s copper market and business developments to gain perspective on…

|

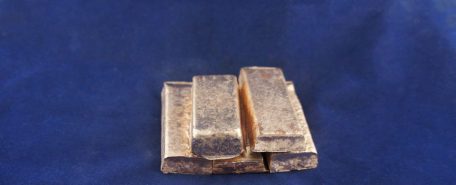

This material offers the highest strength and hardness of all the BeCu alloys with excellent wear resistance and fluidity. Also offers extremely fine detail pick-up in ceramic or pressure cast processes. This also has the lowest pouring temperature of the BeCu alloys allowing almost any type of molding process to be used. |

|

| Forms: |

|

|---|---|

| Belmont Product Code | 4971 |

| Nominal Composition: |

|

|---|

Downloads:

| SDS |

Related products

-

This alloy offers high strength, hardness, wear resistance with excellent fluidity. This alloy is ideal for investment, sand or ceramic casting and provides excellent replication of intricate detail.

Forms: - 2-5 Ingot

- 2" Cut Bars

- 1" Cut Bar

- 1/2" Polished Cubes

- 1/2" x 14 Mesh Shot

Belmont Product Code 4977 Nominal Composition: - 97.2% Cu, 2.05% Be, 0.5% Co, 0.25% Si

-

This alloy exhibits good strength, coupled with excellent corrosion resistance and material toughness properties. This comparatively lower percentage Beryllium alloy provides thermal conductivity properties that are far superior to most Aluminum, Magnesium & Steel alloys.

Forms: - 2" Cut Bars

- 2-20 Ingot

- 2-5 Ingot

Belmont Product Code 4972 Nominal Composition: - 96.8% Cu

- 0.65% Be

- 2.55% Co

-

A Beryllium containing copper base master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts.

Forms: - Approx. 1" Pcs.

- 1/2" and Down Shot

- Slabs

Belmont Product Code 4962 Nominal Composition: - 96% Cu

- 4% Be

RELATED POSTS

Why Companies Are Switching from Lead to Bismuth for Copper and Tin Alloys

Are you looking for an alternative to lead-based alloys? Many companies are moving away from lead and copper and tin alloys due to the regulations and toxicity associated with the heavy metal, and that often means choosing bismuth. The good news is that bismuth has a relatively low melting point, and it’s durable and malleable…

Benefits of Adding Silicon to Brass & Bronze Alloys for Certain

When certain materials are added to copper it changes the physical and mechanical composition of the metal. Two such materials are tin and zinc. Copper that has tin added into it is considered bronze. Bronze alloys provide a very hard metal that can sometimes be brittle and inflexible. When zinc is added to copper, it…

Bell Metals: Properties and Uses in the Musical Industry

When out for a walk by a church or watching a marching band in a parade, you may have listened to the deep ringing tones of a bell or strikes against a cymbal. Such melodious vibrating sounds are created due to the specific type of metal that is used. Bell metals have been around for…

Shot and Cubed Alloys: Advantages of Using Different Shaped Metals

Due to advanced manufacturing processes, companies today can use a range of base metals and alloys to create the right products and components to their industries. When obtaining the metals that will be used in casting, extruding and forming processes, manufacturers can request the alloys and base metals in various sizes and shapes. Ingots, cubes,…

Copper Preventing Future Pandemics? Research Study Evaluates the Metal’s Anti-Microbial Properties

When working with commercial and industrial manufacturing operations, many companies use specific metals in their applications due to their inherent capabilities. One of the most common metals used is copper, as Belmont Metals offers copper metal, copper alloys, and copper-master alloys such as beryllium copper, lithium copper and zirconium copper to manufacturers, jewelers, artists, and…

Magnesium and Copper Alloys: Benefits and Applications

Copper is well known for its electrical and thermal conductivity. It’s often used for electrical wiring purposes and electrical contacts for small and large applications. This metal is also considered a very soft material, as its malleability allows it to be worked into wires and cables. To add strength without impacting its ductility, magnesium is…

The Difference Silicon Bronze and Silicon Brass for Art Casting Applications

Craftspeople have been casting with bronze for so long that the BBC called it the “first alloy.” Introduced around 3,500 BC and typically made with mostly copper and tin, items made with bronze offered a more durable alternative to coper alone. Artifacts from brass have been dated to 500 BC. Brass may have been favored…

Brass and Bronze: Popular Use in Home Hardware Applications

Craftsman of home cabinetry, doors, windows and other features require hardware finishings to add functionality and beauty to the room. Home hardware consists of a wide range of applications, including door knockers, knobs, handles, hinges, cabinet pulls, and even air register covers. These items are typically made of a solid metal such as brass and…

Alloy Impurities: Trace Elements Changing the Characteristics of Copper

Throughout industrial and manufacturing operations, you’ll find copper metals used in both equipment and finished products. Pure copper has incredible thermal and conducive properties. It also provides exceptional corrosion resistance. So you’ll often find it in electrical applications and electronic products. In addition, pure copper is very soft and malleable, making it ideal for numerous…

Art Casting with Bronze and Brass

Creating art using the casting process dates back thousands of years as the oldest surviving piece of cast art dates back to 3200 BC. Yet artists today still enjoy creating a range of decorations, statues, figurines, jewelry and other artistic pieces using this process. The procedure involves using molten metals that are poured into a…

Magnesium Elements: Providing Positive Benefits to Copper and Aluminum Alloys

Alloys on their own can offer a range of mechanical and structural benefits for manufacturers and other industries. Yet your application may require the alloy to have increased strength, workability, or ductility for the particular application. Magnesium is one of many chemical elements that becomes added to other alloys such as copper and aluminum to…

Choosing an Alloy to Get the Best Application Results

Brass and bronze are used in a range of applications, such as component parts for factories, end products for commercial retailers, and creating jewelry for the public. Brass alloys consist of the base metal of copper with varying amounts of zinc added, while bronze contains copper with aluminum, tin, magnesium and other materials. Yet how…

Environmentally Friendly Metals

Are you looking to go green with your manufacturing business? If you are, Belmont Metals has the lead-free, environmentally conscious metals you need to help make your business more productive while protecting the soil and water from lead contamination and reducing the risk of health problems in your employees from accidentally coming into contact with…

Water safety

Lead-free and low-lead alloys keep up with plumbing industry regulations Copper faucets, sinks and appliances have a lustrous color that helps create a warm atmosphere, making a house feel like a home. Copper and its alloys also are functional and durable. They resist corrosion and require little maintenance, which makes red metals an ideal choice…

Playing up Beryllium Copper’s strengths

Ensure you get the most out of this red-metal alloy by understanding its unique properties With each new generation of electronics, laptops get slimmer and more powerful and cell phones have even greater capacities for the amount of apps, music, and streaming sports and television that consumers want to carry around with them. All these…

Bring out the best

Master alloys help copper shine Red metals have played an important role in many cultures, including those of the ancient Egyptians and Romans, who crafted tools, cookware, dishes, mirrors and razors out of copper. Modern uses for copper include electrical, heating/cooling applications, fluid handling and plumbing applications, as well as an increasing demand for the…

Controlling composition using Master Alloys

Create materials that meet specific needs by adding master alloys to the mix It’s important to choose the right materials for a job. Using inferior or unsuitable materials can make completing a project more difficult or even derail it entirely. In the metals industry, combinations of metals, called alloys, are generated to meet the specific…