Soldering is performed in a wide range of industries including plumbing, electronics, heating/AC and manufacturing processes. Selecting the right solder is based on many factors including the solder’s melting temperature range, the properties of the soldering wire for the application, bonding capabilities, and the strength and hardness of the solder. Tin lead wire is a…

|

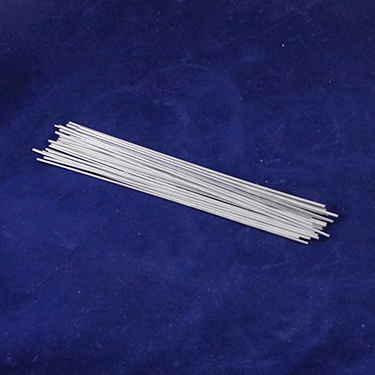

Belmont MAB ( Miter-AL-Braze ) rod is an effective and efficient joining material. While not as hard and strong as our No. I Regular version this item was developed to provide extra ductility. MAB II Hi-Test has often been used by aluminum window manufacturers to join mitered corners, where some bending is required during installation. The strength of an MAB joint in many cases is as great as that of a brazed joint and this material is most commonly used for joining aluminum pieces. |

|

| Forms: |

|

|---|---|

| Belmont Product Code | 8911 |

| Nominal Composition: |

|

|---|

Related products

-

This Copper based brazing alloy acts as a filler metal which is heated above the melting point and distributed between two or more close fitting parts by capillary action. We offer this material in differing Powder sizes as well as half inch cubes.

Forms: - 1/2" Cubes

- 20-40 Mesh Granular

- 40-80 Mesh Granular

Belmont Product Code 4505 Nominal Composition: - Proprietary

-

Belmont MAB ( Miter-AL-Braze ) rod is an effective and efficient joining material. Our regular version is harder and stronger than the MAB II Hi-Test that we also offer. Most users find the No. 1 Regular to be effective for general purposes. The strength of an MAB joint in many cases is as great as that of a brazed joint and this material is most commonly used for joining aluminum pieces.

Forms: - 1/8" x 18" Cast Strip

- 1/8" x 12" Cast Strips

- 1/8" x 18"Cast Strips

- 3/16" x 18" Cast Strips

- 3/32" x 18" Rods

- 3/32" x 36" Cast Strips

- 3/32" x 36" Cast Strips

Belmont Product Code 8934 Nominal Composition: - Proprietary

-

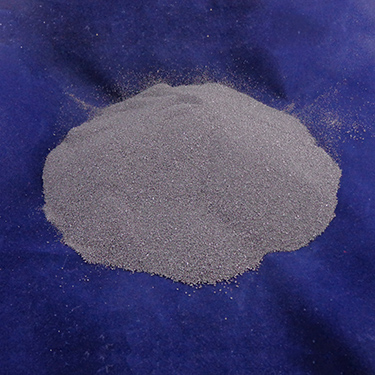

This Fine mesh Brazing Solder has a lower melting temperature than our other Holtite versions and is Aluminum & Silicon based.

Forms: - 100 Mesh & Down Powder

- 30 - 60 Mesh Granular

- 40 - 100 Mesh Granular

Belmont Product Code 1503D Nominal Composition: - Proprietary

RELATED POSTS

MAB Rods for Soldering Aluminum Joints and Corners

Manufacturers and repair people often use soldering or brazing to repair or join two metals together. You can also use Miter-Al-Braze rods to join a variety of aluminum alloys. These alloy rods and the MAB technique will offer often offer you excellent corrosion resistance, appearance, and strength. Two products to consider include the Belmont MAB…

Applications Using Low Melting Alloys

Low melting alloys are considered fusible alloys because they melt at temperatures below 300 degrees are often combined with other metals in order to increase certain properties. For example, Bismuth is often combined with tin and/or silver to create lead-free solders that are non-toxic. Low Melting Alloy Applications and Uses Low melting alloys can be…

Creating complex shapes

Powdered metals help engineers produce parts cost-effectively What is the best way to make a 3-D part out of metal? It depends. There are a number of considerations involved, including time and money. To create parts, manufacturers can choose either a subtractive or an additive manufacturing process. Subtractive manufacturing involves taking a block of material…