Zinc-Based Alloys

Zinc Alloys

Featuring pure Zn shot for precious metal alloying and other uses; Zn plating anodes; Superdie and other Zn alloys for rubber-mold and permanent mold casting, ultrasonic solders.

View more

Solders

Featuring: Body solders, Lead-base, Lead-free solders, Low melting solders, Miter-Al-braze (MAB), Tin-Antimony solders, Tin-base, Tin-Cadmium solders, Tin-Lead solders, Tin-Zinc solders

View more

White Metals

Featuring Aluminum, Lead, Pewter, Solders, Jewelry, Sculpture, Tin, Zinc Alloys in a variety of forms for many applications

View more

Anodes:Cathodic

Featuring Mil Spec zinc anodes, MIL-DTL-18001 (Type ZHS, ZHB, ZSS, ZEP, and more) and ultra-pure anodes to ASTM B418 Type II.

View more

Anodes: Electroplating

Featuring a wide variety of alloys and shapes for all electroplating processes including INCO Nickel, High Grade Zinc, CDA 101 Copper.

View more

Brazing Alloys

Featuring Holtite Alloys and Miter-Al-Braze Alloys for Aluminum Metal Joining

View moreFeatured Products

-

Can be used for various soldering methods including Wave, Selective, and Hand. Known for best in class yields, this material outperforms all Sn/Cu based materials and delivers excellent performance across a wide range of Flux Technologies. SAC305 is used to stabilize the copper content in the wave solder bath depending on process conditions. Forms: - Regular Bar

- Shot

- Ingot

Belmont Product Code 7972 Nominal Composition: - Sn: 96.5%

- Ag: 3%

- Cu: 0.5%

Technical Info: - Solidus: 217 C (423 F)

- Liquidus: 220 C (428 F)

-

-

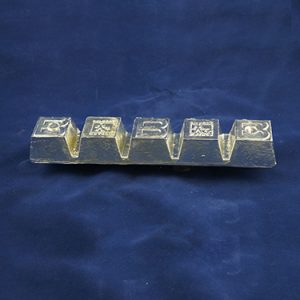

This is our Original, Lead Free, Zinc Based Alloy that works well in Spin Cast Vulcanized Silicone Molds for designs with thick cross sections or minimal detail. Contains Proprietary Grain Refiners for improved casting properties. Forms: - 4-20 lb. KZ Ingot

Belmont Product Code 892NS1 Nominal Composition: - 90-94% Zinc in a Proprietary Formula

Technical Info: - Elongation : 8%

- Liquidus Temperature: 734F

- Pouring Temperatire: 800 F - 875 F

- Density: .244 lbs / Cu. In.

- Tensile Strength: 54,000

- Compression Strength: 68,800 psi

- Brinell Hardness: 146

- Finishes: Mechanical, chemical, organic, and electro-deposited, plastic

-

Our pencil anodes, or engine anodes, are consumed by electrolytic action that would otherwise corrode and harm your equipment. They come with hex brass plugs that vary in in size from 1/4" to 1". Length of the rod varies, from 1" to 24". Forms: - .375" Dia., 3/8-16 NC Thread, 1/4" NPT Plug Size

- .500" Dia., 3/8-16 NC Thread, 3/8"" NPT Plug Size

- .675" Dia., 3/8-16 NC Thread, 1/2" NPT Plug Size

- .750" Dia., 5/8-11 NC Thread, 3/4" NPT Plug Size

- .840" Dia., 1/2" NPT, 1" NPT Plug Size

- Length of the rod varies, from 1" to 24".

Belmont Product Code 8001PEN Nominal Composition: - 99.55% Zn

- Bal

-

Anode assembly includes brass retaining plug and replaceable zinc elements. The first element screws into the the one preceding it. Forms: - Plug NPT Sizes: 3/8", 1/2", 3/4", 1"

- Zinc Element options: .500" dia x .750" ht., .625" dia. x .750" ht, .825" dia. x .750" ht., 1.050" dia. x .750" ht

Belmont Product Code 8001ZDM Nominal Composition: - 99.55% Zn

- Bal

-

-

-

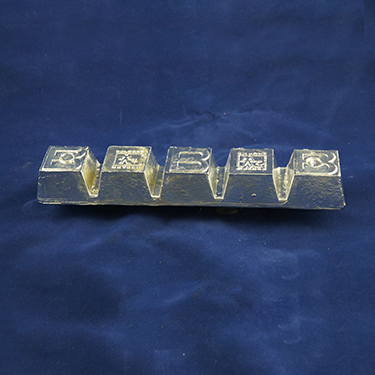

Commercial Zinc base alloy, it contains approximately 15% Aluminum and 85% Zinc. Specially formulated and metallurgically designed to provide superior casting results in Spin-Casting applications. Forms: - 4-16 Ingot

Belmont Product Code 8853 Nominal Composition: - 85% Zn

- 15% Al

-

Zamak 12 offers high hardness and high tensille strenght. This is the preferred alloy for permanent mold applications although it can also be cold-chamber die-cast with excellent results. It combines low temperature melting efficiency and thin wall capabilities with premium mechanical properties. ZA-12 can usually be poured directly into molds designed for aluminum and brass. Forms: - 4-20 Ingot

Belmont Product Code 8871 Nominal Composition: - 88% Zn

- 11% Al

- 1% Cu

-

Zinc/Aluminum solder 99% Zinc and 1% Aluminum. Used by the Romans and is commonly used today, particularly in musical instruments and many hardware applications that must resist corrosion. Zinc is an alloy with Lead and Tin to make solder, a metal with a relatively low melting point used to join electrical components, pipes and other applications. Forms: - 4-20 Ingot

Belmont Product Code 8995 Nominal Composition: - 99% Zn

- 1% Al

-

Slush Cast alloy is a high purpose-engineered product. This alloy was developed to provide a high fluidity casting material capable of producing a good surface definition when cast in metal permanent molds or rubber molds. It contains approximately 5% Aluminum and 95% Zinc. It is used primarily for the use of hollow castings. Forms: - 4-20 Ingot

Belmont Product Code 8952 Nominal Composition: - 95% Zn

- 5% Al

-

Zamak 3 is a family of alloys with a base metal of zinc and alloying elements of aluminum, magnesium and copper. It is the most commonly used in Zinc die casting, providing an excellent combination of strenght, ductility. It also provides excellent plating and finishing characteristics. This alloy is the designers first choice for die casting applications and the most widely used in North America. Forms: - 4-20 Lb. Ingot

Belmont Product Code 8961 Nominal Composition: - 96% Zn

- 4% Al

-

Zamak 7 is a modification of Zamak 3. However, Zamak 7 has higher ductility (for Forming and bending operations) and the highest casting fluidity of the Zamak family. Excibits excellent damping capacity and vibration attenuation in comparison with aluminum die casting alloys. Forms: - 4-20 Ingot

Belmont Product Code 8962 Nominal Composition: - 95.87% Zn

- 4.1% Al

- 0.015% Mg

- 0.015% Ni

-

This Solder has good corrosion resistance and tensile strength. With a melting range beginning at 390 Deg. F. it avoids causing damage to critical electronics as well preventing substrate deformation and segregation. It is used very often in spray wire form for capacitors and other electronic parts. Forms: - 1/16" Dia. Plus .000" Minus .004" on 5 Lb. Spools

- 2-5 Ingot

- Cast Flat Anodes

Belmont Product Code 7601DS1C Nominal Composition: - 60.5% Sn

- 39.5% Zn

-

This is a Bismuth based non-eutectic alloy commonly used as a low-melting solder and also to make custom shaped blocks. It is also used to make metal inlays in wood and also useful for repairing antiques as the low melting temperature of Wood's metal makes it unlikely this will harm the original piece. Forms: - 1/4" Dia. Solid Wire

- 1/8" Dia Solid Wire

Belmont Product Code 2502DS1C Nominal Composition: - 12.5% Sn

- 25% Pb

- 50% Bi

- 12.5% Cd

-

Lead Silver solders such as this have physical properties - tensile, creep, and shear strength - which are good to 350 Deg. F. Fatigue properties are also better than the non silver solder alloys. Forms: - .063 Dia. Solid Wire

- 5Lb. Spools

- Capping Bars

Belmont Product Code 5951DS1C Nominal Composition: - 60% Sn

- 40% Pb

- 5.5% Ag

-

Tin-Lead solders is the largest single group and the most widely used of the soldering alloys . Tin-Lead solders are compatible for use with all types of base metal cleaners, fluxes, and heating methods. 60/40 Tin Lead solder, almost the eutectic is particularly adaptable to delicate work or when soldering temperature may be critical. This particular item comes in 1/16" Diameter and can also be offered in other sizes as well. This is also a quick setting solder for fine electrical and tinsmith work. Forms: - 1/16" Dia. Solid Wire

Belmont Product Code 76001DSC Nominal Composition: - 60% Sn

- 40% Pb

-

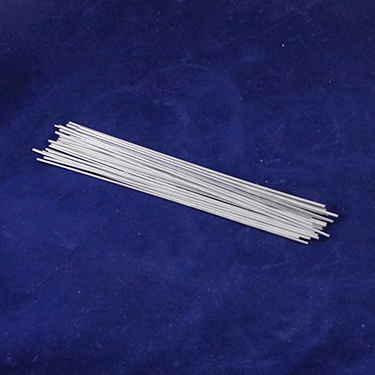

Belmont MAB ( Miter-AL-Braze ) rod is an effective and efficient joining material. Our regular version is harder and stronger than the MAB II Hi-Test that we also offer. Most users find the No. 1 Regular to be effective for general purposes. The strength of an MAB joint in many cases is as great as that of a brazed joint and this material is most commonly used for joining aluminum pieces. Forms: - 1/8" x 18" Cast Strip

- 1/8" x 12" Cast Strips

- 1/8" x 18"Cast Strips

- 3/16" x 18" Cast Strips

- 3/32" x 18" Rods

- 3/32" x 36" Cast Strips

- 3/32" x 36" Cast Strips

Belmont Product Code 8934 Nominal Composition: - Proprietary

-

Belmont MAB ( Miter-AL-Braze ) rod is an effective and efficient joining material. While not as hard and strong as our No. I Regular version this item was developed to provide extra ductility. MAB II Hi-Test has often been used by aluminum window manufacturers to join mitered corners, where some bending is required during installation. The strength of an MAB joint in many cases is as great as that of a brazed joint and this material is most commonly used for joining aluminum pieces. Forms: - 1/8” X 18” Cast Strip

- 3/32” X 18” Cast Strip

- Ingot

Belmont Product Code 8911 Nominal Composition: - Proprietary

-

This Copper based brazing alloy acts as a filler metal which is heated above the melting point and distributed between two or more close fitting parts by capillary action. We offer this material in differing Powder sizes as well as half inch cubes. Forms: - 1/2" Cubes

- 20-40 Mesh Granular

- 40-80 Mesh Granular

Belmont Product Code 4505 Nominal Composition: - Proprietary

-

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - Cast Flat Top Anode Approx 1-1/4" Each

- 1" x 1" x 1" Nuggets

Belmont Product Code 48012A Nominal Composition: - 20% Zn

- 80% Cu

Technical Info: - CDA #: 87300

-

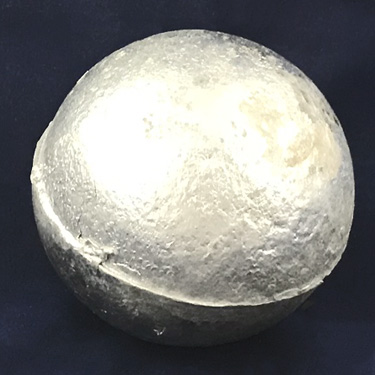

Zinc metal coatings provide better protection on Iron and Steel than any other corrosion resistant coatings. Plated SHG Zinc coatings are pure compared to hot dipped and are also thinner and more ductile, which allows them to be made brighter and more lustrous. We offer this material in 2" diameter balls that are solid and clean and do not have any flash orgates which would cause backet hang ups. Forms: - 2" Diameter Balls

Belmont Product Code 8000AG Nominal Composition: - 99.99% Zn

-

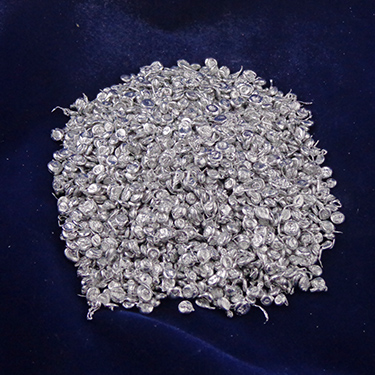

Mainly used in galvanizing steel to prevent rusting, in zinc die casting alloys and in copper based alloys, such as brass. Zinc is also essential to the growth of many kinds of organisms, both plant and animal. Zinc also extends the life of other material such as steel (by hot dipping or electrogalvanizing), rubber and plastics (as an aging inhibitor) and wood (in paints). Forms: - Flat Tops

Belmont Product Code 8000AM Nominal Composition: - 99.99% Zn

-

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - 1" x 1" x 1" Nuggets

- Cast Flat Top Anode Approx 1-1/4" Each

Belmont Product Code 47018A Nominal Composition: - 30% Zn

- 70% Cu

Technical Info: - CDA #: 96400

-

Belmont manufactures style B round anodes for Cathodic Protection of steel hulls & tanks. Available with either 3/8" or 1/2" IPS. The 11" piece has 2 3/4" IPS. Forms: - 2" Diameter x 1" Thick Circle

- 3" Diameter x 1" Thick Circle

- 4" Diameter x 1" Thick Circle

- 5" Diameter x 1" Thick Circle

- 6" Diameter x 1" Thick Circle

- 9" Diameter x 1" Thick Circle

- 11" Diameter x 1" Thick Circle

Belmont Product Code 8001B Nominal Composition: - 99.55% Zn

- Bal

-

-

-

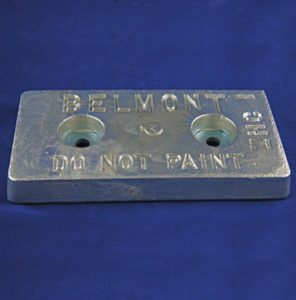

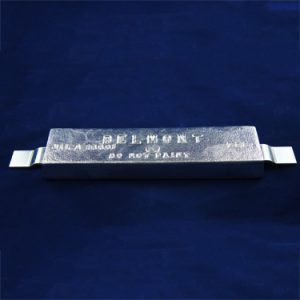

Available for welding or bolt on applications to meet most any requirements for Industrial use or for sale to US Government. Forms: - 1-1/4" x 6" x 12" with Core Strap and 2 Recessed Holes (ZHC-23)

- 2 1/2" x 6" x 12" with Core Strap and 2 Recessed Holes (ZHC-42)

Belmont Product Code 8001ZHC Nominal Composition: - 99.55% Zn

- Bal

-

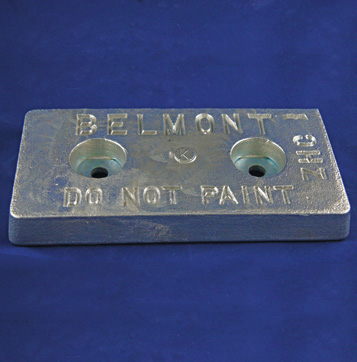

Available for welding or bolt on applications to meet most any requirements for Industrial use or for sale to US Government. Forms: - 1-1/4" x 3" x 12" with 1 Steel Strap approx. 11.5 lbs

- 2 1/2" x 3 1/2" x 12" with 1 Steel Strap approx. 24 lbs

Belmont Product Code 8001ZSS Nominal Composition: - 99.55% Zn

- Bal

-

-

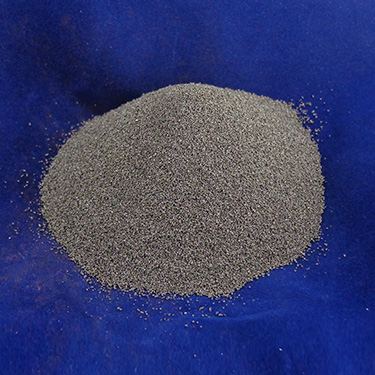

This solder filler has a lower melting temperature than our brazing alloys. In solder joints the base metals will typically be much stronger than the solder following the soldering process. Forms: - 40-120 Mesh

Belmont Product Code 4508 -

This Fine mesh Brazing Solder has a lower melting temperature than our other Holtite versions and is Aluminum & Silicon based. Forms: - 100 Mesh & Down Powder

- 30 - 60 Mesh Granular

- 40 - 100 Mesh Granular

Belmont Product Code 1503D Nominal Composition: - Proprietary