Copper-Based Alloys

Anodes: Electroplating

Featuring a wide variety of alloys and shapes for all electroplating processes including INCO Nickel, High Grade Zinc, CDA 101 Copper.

View more

Beryllium Copper

Featuring Beryllium Copper Alloys in a Variety of forms; 4% Beryllium Copper, Beryllium Copper Alloys: 20C, 10C, 70C, 165C, 275C and more

View more

Brass and Bronze

Featuring Silicon Bronze Everdur, Silicon Bronze, Special H Silicon Brass, Art Casters Brass, White Bronze, and many other different Brass alloys meeting CDA specifications

View more

Brazing Alloys

Featuring Holtite Alloys and Miter-Al-Braze Alloys for Aluminum Metal Joining

View more

Copper Alloys

Featuring a wide variety of Copper-Based Alloys meeting CDA specifications, Brass and Bronzes for Jewelry and Sculpture, Copper-Based Master Alloys, and Custom Alloys

View more

Copper Master Alloys

with: Beryllium, Boron, Cadmium, Chromium, Iron, Lithium, Magnesium, Manganese, Nickel, Phosphorous, Silicon, Tellurium, Titanium, Zinc, Zirconium

View more

Deoxidizers and Degasifiers

Featuring 2% boron-copper and 2% lithium-copper hardeners, master alloys, deoxidizers, and degasifiers.

View more

Jewelry Alloys

Featuring: Art Caster’s Brass, Beryllium Copper, Brittania, Electrolytic Copper, Everdur, Jeweler’s Manganese Bronze, Nickel-Silver, Pewters, Superdie Zinc Alloys, and White Bronze

View more

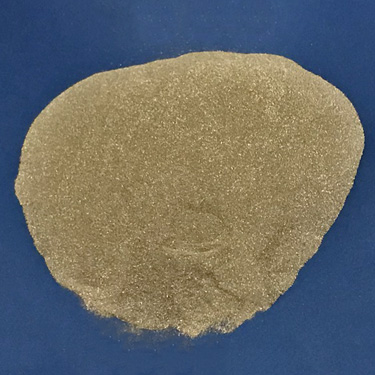

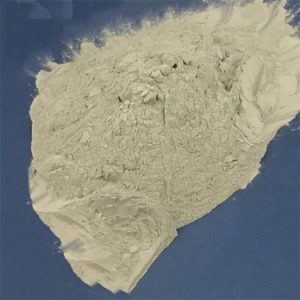

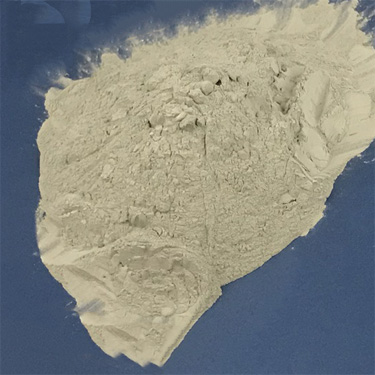

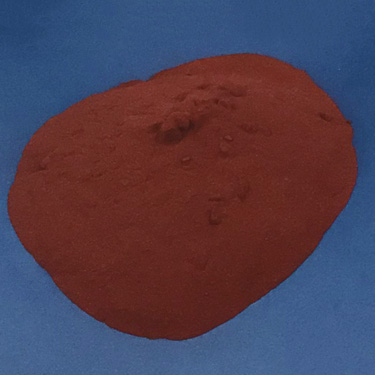

Powdered Metals

Featuring: Holtite Alsil Grit, Iron Powder, High Grade Zinc, Tin, and Copper-Aluminum Applications

View more

Sculpture Alloys

Featuring Everdur Silicon Bronze, Art Caster’s Brass, Special H Silicon Bronze, Beryllium Copper, Jewelers’ Manganese Bronze, and White Bronze.

View moreFeatured Products

-

This alloy is used to introduce Titanium into Copper alloys which improves strength. Forms: - 1" x 6" x 12" Slabs

Belmont Product Code 47024 Nominal Composition: - 70% Cu

- 30% Ti

-

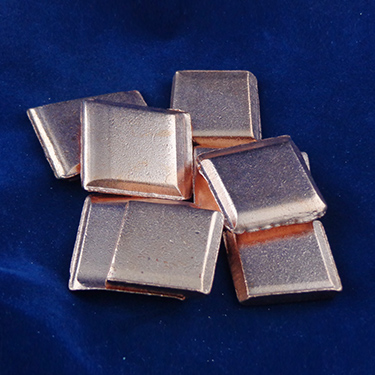

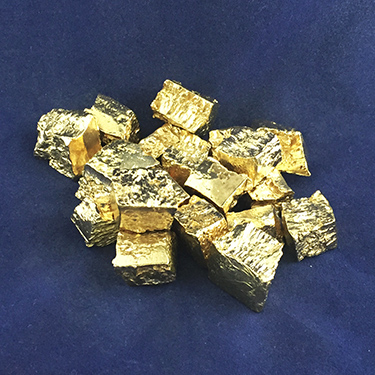

Easily cast White Brass Alloy with good fluidity and high detail. We offer this material in a variety of forms including Ingot, Cut Bars, Cubes and Shot. Forms: - Ingot

- 2" Cut Bar

- 1/2" Polished Cubes

- Shot

Belmont Product Code 45815 Nominal Composition: - Cu: 58%

- Mn: 20%

- Zn: 20%

- Al: 1%

- Pb: 1%

-

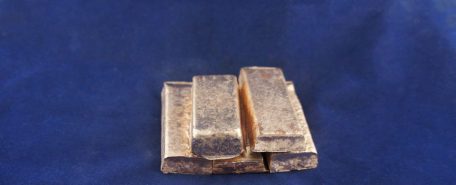

Bell metal is a hard alloy used for making bells and related instruments, such as cymbals. It is a form of bronze with a higher tin content, usually in approximately a 4:1 ratio of copper to tin (typically, 78% copper, 22% tin by mass). We offer this material in Ingot, shot, and cut pieces. Forms: - Ingot

- Irregular Shot

- 1/2" Polished Cubes

- 2" Cut Pieces

Belmont Product Code 4788 Nominal Composition: - Cu: 78%

- Sn: 22%

-

This is our Original, Lead Free, Zinc Based Alloy that works well in Spin Cast Vulcanized Silicone Molds for designs with thick cross sections or minimal detail. Contains Proprietary Grain Refiners for improved casting properties. Forms: - 4-20 lb. KZ Ingot

Belmont Product Code 892NS1 Nominal Composition: - 90-94% Zinc in a Proprietary Formula

Technical Info: - Elongation : 8%

- Liquidus Temperature: 734F

- Pouring Temperatire: 800 F - 875 F

- Density: .244 lbs / Cu. In.

- Tensile Strength: 54,000

- Compression Strength: 68,800 psi

- Brinell Hardness: 146

- Finishes: Mechanical, chemical, organic, and electro-deposited, plastic

-

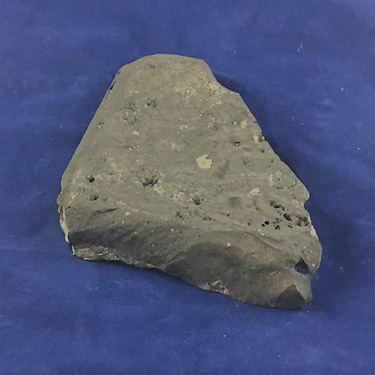

Zirconium acts as a grain refiner in Copper Alloys and can improve mechanical properties. Forms: - 1" x 6" x 12" Broken Slabs

Belmont Product Code 45046 Nominal Composition: - 50% Cu

- 50% Zr

-

Zirconium acts as a grain refiner in Copper Alloys and can improve mechanical properties. Forms: - Broken Slabs

Belmont Product Code 49011 Nominal Composition: - 90% Cu

- 10% Zr

-

-

-

Belmont Special 92% Tin Pewter alloy is an excellent casting alloy with approximately 92% Tin (Tin base alloy). Special Pewter for figurines, models, etc. with heavy sections - better casting characteristics than lead free Britannia. Forms: - 5-6 Ingot

Belmont Product Code 7924 Nominal Composition: - 92% Sn

- 4% Pb

- 4% Sb

-

35% Tin Pewter, Lead, Tin Alloy easy meltable with relatively low melting temperature. Offers opportunity for cost savings where its relatively high weight is not a problem . Offers opportunity for cost savings where its relatively high weight is not a problem. Forms: - 5-8 Ingot

Belmont Product Code 5632 Nominal Composition: - 62% Pb

- 3% Sb

- 35% Sn

-

-

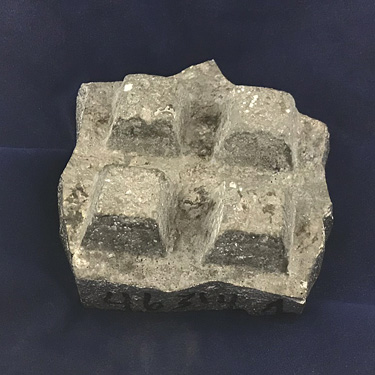

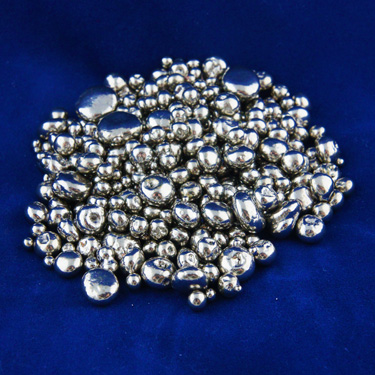

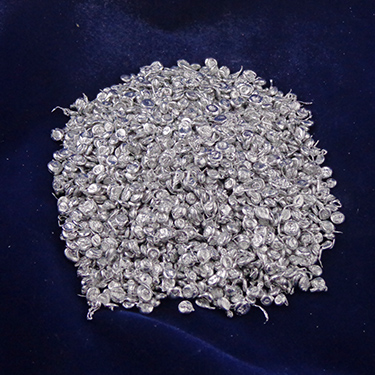

Phos Copper is the most commonly used deoxidizer. Effectively removes oxygen from molten metal with little or no reaction or dross formation. Forms: - 3 Mesh Shot

- Approx. 15 Lb. Waffle Ingots

Belmont Product Code 48514 Nominal Composition: - 85% Cu

- 15% P

-

Compound Degasifier engineered to be effective at removing unwanted gases when used with Nickel Alloys. Forms: - 2" and Down

Belmont Product Code 48515 Nominal Composition: - Proprietary

-

-

Phosphorus is used in tin as in tin solders to suppress dross formation keeping the metal bath cleaner. Forms: - Waffle

Belmont Product Code 7955 Nominal Composition: - 95% Sn

- 5% P

-

-

-

Silicon increases fluidity in brasses and copper nickel alloys. Silicon copper can become a deoxidizer if phosphorous cannot be used. Forms: - 1/2" x 14" Mesh Broken Pieces

- Broken Slabs

Belmont Product Code 4710 Nominal Composition: - 70% Cu

- 30% Si

-

Magnesium is a strong deoxidizer particularly for nickel alloys. As a Copper master alloy it is effective and less reactive. If alloyed, in can improve mechanical properties. Forms: - Broken Slabs

Belmont Product Code 4800 Nominal Composition: - 80% Cu

- 20% Mg

-

-

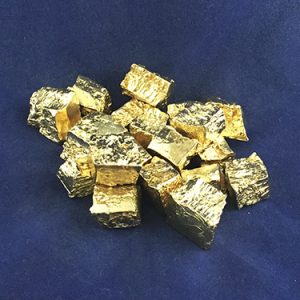

Chrome is an addition generally made in Copper Alloys for corrosion resistance and electrical conductivity. Forms: - 2-10 Ingot

Belmont Product Code 4906 Nominal Composition: - 90% Cu

- 10% Cr

-

-

Lithium has the advantage of being able to combine with both oxygen and hydrogen. Used on its own, Lithium will be more of a deoxidizer. Used in a “duplex treatment”, deoxidizing first, then Lithium can be considered a degasifier now available to be a scavenger for hydrogen and other unwanted gasses. Forms: - 1 Lb. Pcs. 1" X 1" x 4"

- 3-4 Oz. Polished Pieces

- 1" x 6" x 12" Slabs

Belmont Product Code 4981 Nominal Composition: - 98% Cu

- 2% Li

-

Nickel is known to improve corrosion resistance particularly in sea water. This makes it a good choice to improve the properties of marine alloys. Forms: - 2-14 Mesh Polished Shot

Belmont Product Code 45027 Nominal Composition: - 50% Cu

- 50% Ni

-

Manganeze bronze is a high strength and a hard alloy containing manganese and zinc. It's used for highly stressed machine parts. Forms: - 1/2" Polished Cubes

- 2-20 Ingot

Belmont Product Code 4643 Nominal Composition: - 65% Cu

- 25% Zn

- 3% Mn

- 4% Al

- 3% Fe

Technical Info: - CDA #: 86200

-

Navy M Leaded Bronze C92200 Bronze is an alloy of copper, further classified as a bronze (copper-tin- alloy). Is used for a variety of steam pressure applications involving temperatures up to 550 F. Forms: - 1-20 Ingot

Belmont Product Code 4884 Nominal Composition: - 88% Cu

- 4% Zn

- 8% Sn

Technical Info: - CDA #: 90300

-

Navy M Leaded Bronze C92200 Bronze is an alloy of copper, further classified as a bronze (copper-tin- alloy). Is used for a variety of steam pressure applications involving temperatures up to 550 F. Forms: - 20 Lb. Ingots

Belmont Product Code 4888 Nominal Composition: - 88% Cu

- 4.5% Zn

- 6% Sn

- 1.5% Cr

Technical Info: - CDA #: 92200

-

Aluminum Bronze 415A Alloy CDA# 952 "Chemistry ONLY". Aluminum bronze bearings are used in heavy loaded applications. Forms: - 2-20 Ingot

Belmont Product Code 4872 Nominal Composition: - 87.5% Cu

- 9% Al

- 3.5% Fe

Technical Info: - CDA #: 95200

-

Copper-Nickel 90/10 has a very good resistance to uniform and local corrosion in seawater and, as opposed to other copper alloys, is not as susceptible to stress corrosion cracking. Forms: - 2-20 Ingot

Belmont Product Code 49019 Nominal Composition: - 86.85% Cu

- 10% Ni

- 1% Mn

- 1.4% Fe

- 0.75% Cb

Technical Info: - CDA #: 96200

-

Copper-Nickel 70/30 excellent resistance to corrosion and erosion. It's strong and dectile and is utilized in areas where high temperatures and pressures, combined with high velocities and turbulence are serious problems. Forms: - 2-20 Ingot

Belmont Product Code 47025 Nominal Composition: - 66% Cu

- 30.9% Ni

- 0.4% Si

- 1% Mn

- 0.7% Fe

- 1% Cb

Technical Info: - CDA #: 96400

-

Forms: - 2-20 Ingot

Belmont Product Code 4562 Nominal Composition: - 57% Cu

- 20% Zn

- 12% Ni

- 2% Sn

- 9% Pb

Technical Info: - CDA #: 97300

-

A Copper (Cu) Alloy containing Chromium (Cr) used for their high strength and corrosion resistance. It offers high conductivity, good ductivity and strength. Serves as a master alloy to add chrome to various copper alloys. Forms: - 2-20 Ingot

Belmont Product Code 4989 Nominal Composition: - 98.7% Cu

- 1.3% Cr

Technical Info: - CDA #: 81500

- Melting Point (Liquidus): 1985 F, 1085 C

- Melting Point (Solidus): 1967 F, 1075 C

- Density: .319 lb./cu. in. @ 68 F

- Specific Gravity: 8.82

- Thermal Conductivity: 182 Btu./sq. ft./ft./hr/F @ 68 F

- Tensile Strength-ksi: 51

-

Leaded red brass is typically found in plumbing applications. It is known for its reasonable cost with good machining and casting properties. The lead content ensures pressure tightness. Red brass is also used for low-cost bearing materials under low loads. Forms: - 1" x 6" x 12" Slabs

- 2-20 Ingot

- 2" Sheared Pcs.

Belmont Product Code 4852 Nominal Composition: - 85% Cu

- 5% Zn

- 5% Sn

- 5% Pb

Technical Info: - CDA #: 83600

-

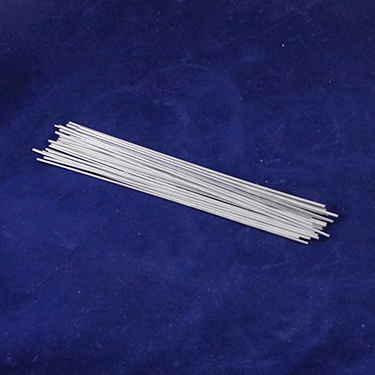

Belmont MAB ( Miter-AL-Braze ) rod is an effective and efficient joining material. Our regular version is harder and stronger than the MAB II Hi-Test that we also offer. Most users find the No. 1 Regular to be effective for general purposes. The strength of an MAB joint in many cases is as great as that of a brazed joint and this material is most commonly used for joining aluminum pieces. Forms: - 1/8" x 18" Cast Strip

- 1/8" x 12" Cast Strips

- 1/8" x 18"Cast Strips

- 3/16" x 18" Cast Strips

- 3/32" x 18" Rods

- 3/32" x 36" Cast Strips

- 3/32" x 36" Cast Strips

Belmont Product Code 8934 Nominal Composition: - Proprietary

-

Belmont MAB ( Miter-AL-Braze ) rod is an effective and efficient joining material. While not as hard and strong as our No. I Regular version this item was developed to provide extra ductility. MAB II Hi-Test has often been used by aluminum window manufacturers to join mitered corners, where some bending is required during installation. The strength of an MAB joint in many cases is as great as that of a brazed joint and this material is most commonly used for joining aluminum pieces. Forms: - 1/8” X 18” Cast Strip

- 3/32” X 18” Cast Strip

- Ingot

Belmont Product Code 8911 Nominal Composition: - Proprietary

-

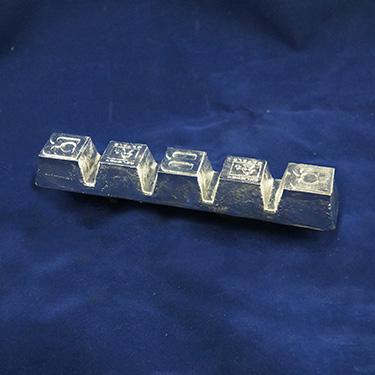

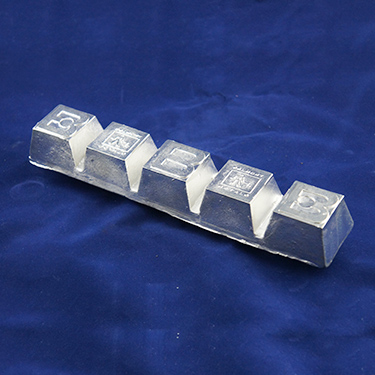

This Copper based brazing alloy acts as a filler metal which is heated above the melting point and distributed between two or more close fitting parts by capillary action. We offer this material in differing Powder sizes as well as half inch cubes. Forms: - 1/2" Cubes

- 20-40 Mesh Granular

- 40-80 Mesh Granular

Belmont Product Code 4505 Nominal Composition: - Proprietary

-

Master Alloy used in the production of Copper Alloys for a wide variety of industries. The introduction of Boron to Copper Alloys helps eliminate gas and porosity without the loss of conductivity. Forms: - 1/2" and Down Polished Shot

Belmont Product Code 49817 Nominal Composition: - 98% Cu

- 2% B

-

Can be considered either a deoxidizer or grain refiner. Generally, for pure copper its role would be deoxidizing but in brasses it’s more of a grain refiner. Forms: - 3/4" & Down Polished Shot

- 3/4" & Down Unpolished Shot

- 40-15 Waffle

- 4-5 Oz Pcs.

Belmont Product Code 4987 Nominal Composition: - 98% Cu

- 2% B

-

This alloy offers high strength, hardness, wear resistance with excellent fluidity. This alloy is ideal for investment, sand or ceramic casting and provides excellent replication of intricate detail. Forms: - 2-5 Ingot

- 2" Cut Bars

- 1" Cut Bar

- 1/2" Polished Cubes

- 1/2" x 14 Mesh Shot

Belmont Product Code 4977 Nominal Composition: - 97.2% Cu, 2.05% Be, 0.5% Co, 0.25% Si

-

This alloy exhibits good strength, coupled with excellent corrosion resistance and material toughness properties. This comparatively lower percentage Beryllium alloy provides thermal conductivity properties that are far superior to most Aluminum, Magnesium & Steel alloys. Forms: - 2" Cut Bars

- 2-20 Ingot

- 2-5 Ingot

Belmont Product Code 4972 Nominal Composition: - 96.8% Cu

- 0.65% Be

- 2.55% Co

-

With the highest Copper content of all BeCu alloys this alloy offers superior strength and hardness along with superior thermal conductivity. It is recommended for Investment, continuous and centrifugal casting methods. Forms: - 2-5 Ingot

Belmont Product Code 4992 Nominal Composition: - 99.12% Cu

- 0.08% Be

- 0.8% Cr

-

This Beryllium Copper alloy provides good resistance to corrosion along with high strength and hardness. It is very suitable for salt water immersion applications and also offer excellent replication of intricate detail. Forms: - 2" Cut Bars

- 2-5 Ingot

Belmont Product Code 4986 Nominal Composition: - 98% Cu

- 1.7% Be

- 0.3% Co

-

This material offers the highest strength and hardness of all the BeCu alloys with excellent wear resistance and fluidity. Also offers extremely fine detail pick-up in ceramic or pressure cast processes. This also has the lowest pouring temperature of the BeCu alloys allowing almost any type of molding process to be used. Forms: - 1/2" and Down Polished Shot

- 1/2" X 14 Mesh Unpolished Shot

- 2-5 Ingot

Belmont Product Code 4971 Nominal Composition: - 96.43% Cu

- 2.7% Be

- 0.5% Co

- 0.3% Si

- 0.07% Ti

-

A Beryllium containing copper base master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts. Forms: - Approx. 1" Pcs.

- 1/2" and Down Shot

- Slabs

Belmont Product Code 4962 Nominal Composition: - 96% Cu

- 4% Be

-

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - Cast Flat Top Anode Approx 1-1/4" Each

- 1" x 1" x 1" Nuggets

Belmont Product Code 48012A Nominal Composition: - 20% Zn

- 80% Cu

Technical Info: - CDA #: 87300

-

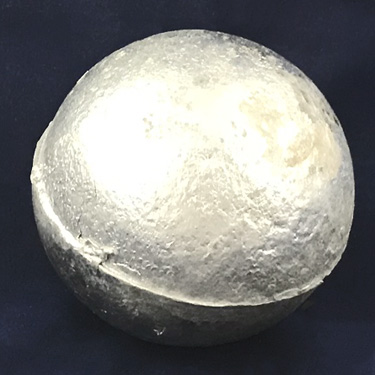

Zinc metal coatings provide better protection on Iron and Steel than any other corrosion resistant coatings. Plated SHG Zinc coatings are pure compared to hot dipped and are also thinner and more ductile, which allows them to be made brighter and more lustrous. We offer this material in 2" diameter balls that are solid and clean and do not have any flash orgates which would cause backet hang ups. Forms: - 2" Diameter Balls

Belmont Product Code 8000AG Nominal Composition: - 99.99% Zn

-

Mainly used in galvanizing steel to prevent rusting, in zinc die casting alloys and in copper based alloys, such as brass. Zinc is also essential to the growth of many kinds of organisms, both plant and animal. Zinc also extends the life of other material such as steel (by hot dipping or electrogalvanizing), rubber and plastics (as an aging inhibitor) and wood (in paints). Forms: - Flat Tops

Belmont Product Code 8000AM Nominal Composition: - 99.99% Zn

-

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - 1" x 1" x 1" Nuggets

- Cast Flat Top Anode Approx 1-1/4" Each

Belmont Product Code 47018A Nominal Composition: - 30% Zn

- 70% Cu

Technical Info: - CDA #: 96400

-

This solder filler has a lower melting temperature than our brazing alloys. In solder joints the base metals will typically be much stronger than the solder following the soldering process. Forms: - 40-120 Mesh

Belmont Product Code 4508 -

This Fine mesh Brazing Solder has a lower melting temperature than our other Holtite versions and is Aluminum & Silicon based. Forms: - 100 Mesh & Down Powder

- 30 - 60 Mesh Granular

- 40 - 100 Mesh Granular

Belmont Product Code 1503D Nominal Composition: - Proprietary