Babbitt metals are either lead or tin based, and the metal makes excellent bearings that are easy to pour as a DIY project. However, before you pour your bearings, you must select the correct babbitt metal in order to ensure your engine or piece of machinery operates correctly and efficiently. If you know the composition…

Featuring tin-base and lead-base babbitt to ASTM, SAE, government, Navy specifications; special and custom alloys.

The use of bearing materials to reduce bearing friction can be traced at least back to the Roman chariot days. Soft metals such as Tin and Lead were unsuccessfully tried in the 1700’s; but, it was not until 1839 that Isaac Babbitt patented a bearing with a Steel or Bronze shell lined with a Tin-base alloy. The alloy mentioned in the patent was 89% Tin, 9% Antimony and 2% Copper, which is amazingly close to today’s very popular ASTM B-23 Grade 2 “Babbitt” was originally applied to Tin-base alloys, it is now used to describe bearing metals with Lead or other metals as the major element.

Belmont Babbitt Metals are manufactured under strict metallurgical control to provide sufficient softness for excellent conformability and embeddability, thereby offering good fluid-forming properties. They are easily cast, can be rigidly bonded to Cast Iron, Steel or Bronze, will run satisfactory against a Steel shaft, and show excellent corrosion resistance. Given suitable design of a bearing assembly, a properly selected Belmont Babbitt alloy will give effective service under a wide variety of conditions

In addition the traditional method of pouring molten Babbitt to form the bearing surface, Babbitt is often sprayed onto the bearing surface using Babbitt wire in metallizing equipment. The apray method is also used to seal the ends of rolled or stacked electronic condensors.

Belmont offers a broad range of both Tin and Lead-base Babbitt alloys to meet requirements for most common applications. We also invite inquiries on Cadmium-base, Copper-base, Aluminum-base, and Zinc-base bearing alloys.

Forms Available

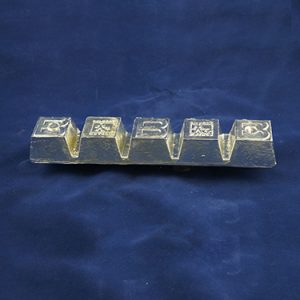

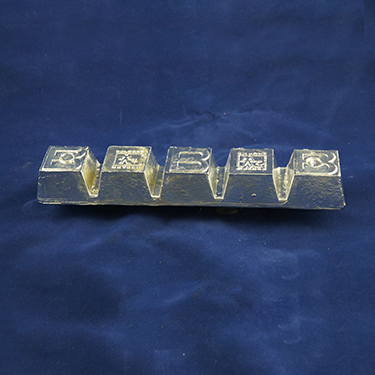

Belmont Babbitt metals are provided as 40-lb. ingots, or as smaller ingots, six to eight lbs., with five sections, and wire for flame spraying/metallizing applications

Read More

Showing all 15 results

Featured products

RELATED POSTS

How to Pour Babbitt Bearings

Do you have old babbitt bearings that need to be replaced? Babbitt is a special type of metal that was designed for use as bearings due to its heat resistance and durability. The metal is normally comprised of varying percentages of copper, antimony, lead, arsenic and tin. The exact percentages vary, according to the grade….

Antimony: Possessing Durability and Versatility When Alloyed with Other Metals

Semiconductors, machine bearings, and utensils are all made from varying amounts of metal alloys. Yet these items also possess one common factor: antimony. Antimony is a semi-metal element that comes in both a powdered form as well as a hard and brittle metal. Possessing a silvery, blush white appearance, this element is highly desired when…

Smooth operation

Choosing the right Babbitt alloy helps to increase a bearing’s useful life Reliable machine operation depends on a properly working bearing assembly. If there is a failure within the bearing, such as a decrease in lubrication, the resulting heat from friction can not only decrease the life of the bearing but also cause equipment to…

Keep on rolling

Babbitt metals ensure machinery runs smoothly Bearings play an integral role in machine efficiency by reducing friction between moving parts. The earliest recorded examples of bearing usage date back to the Romans, and in the year 1500, Leonardo da Vinci sketched a design for a helicopter that incorporated ball bearings. Today, common types of bearings…