Copper’s immense popularity in products made around the world requires manufacturers to develop this alloy in high quantities to meet rising demand. However, copper by itself is often not suitable for products when it is melted and cast into shape. Its soft properties require strengthening yet also elasticity so it does not become brittle. In…

with: Beryllium, Boron, Cadmium, Chromium, Iron, Lithium, Magnesium, Manganese, Nickel, Phosphorous, Silicon, Tellurium, Titanium, Zinc, Zirconium

Belmont Copper Master Alloys are alloying elements manufactured from high purity Copper and is combined with a high percentages of one or more elements. Our alloys enable casting houses and ingot manufacturers to overcome problems associated with alloying that they may experience when working with molten metals.

Master Alloys are commonly used as additives in the manufacture of other alloys or as deoxidants, degasifiers, desulphurizing agents or of similar use in the metallurgy of non ferrous metals. A Master Alloy can be referred to as a “hardener”, “grain refiner” or “modifier”, depending on the application

There are several reasons for adding a Master Alloys to a melt, the main one being selective composition adjustment. They are used to modify the composition of the molten metal, allowing you to achieve a desired chemical specification. A second important application is for specific performance requirements. Master Alloys have the ability to change the micro-structure of a metal during casting and solidification in order to change its properties. Properties that can be modified include: castability, surface finish, electrical conductivity, mechanical strength or ductility.

The use of a Master Alloy instead of a pure metal can be for economical reasons, since certain elements will have a poor yield or create high losses when melted in pure form. Technical issues may also prevent the pure metals from dissolving completely or the required furnace temperature is too high for a basic casting operations equipment. Our Master Alloys provide the solution by dissolving quicker at lower temperatures while saving valuable time and energy.

Applications: Used to enhance properties of Copper Alloys to increase fluidity, hardness, color, ductility, and others

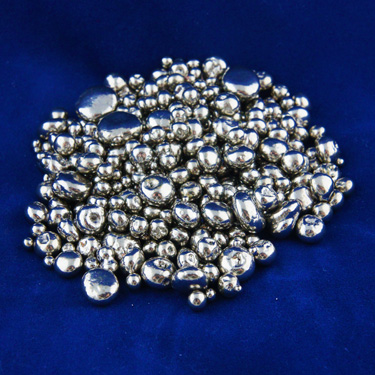

Forms: Slab, Ingot, Cut Bar, Cubes, Shot

Read More

Showing all 34 results

Featured products

-

Lithium has the advantage of being able to combine with both oxygen and hydrogen. Used on its own, Lithium will be more of a deoxidizer. Used in a “duplex treatment”, deoxidizing first, then Lithium can be considered a degasifier now available to be a scavenger for hydrogen and other unwanted gasses. Forms: - 1 Lb. Pcs. 1" X 1" x 4"

- 3-4 Oz. Polished Pieces

- 1" x 6" x 12" Slabs

Belmont Product Code 4981 Nominal Composition: - 98% Cu

- 2% Li

-

Can be considered either a deoxidizer or grain refiner. Generally, for pure copper its role would be deoxidizing but in brasses it’s more of a grain refiner. Forms: - 3/4" & Down Polished Shot

- 3/4" & Down Unpolished Shot

- 40-15 Waffle

- 4-5 Oz Pcs.

Belmont Product Code 4987 Nominal Composition: - 98% Cu

- 2% B

-

-

Silicon increases fluidity in brasses and copper nickel alloys. Silicon copper can become a deoxidizer if phosphorous cannot be used. Forms: - 1/2" x 14" Mesh Broken Pieces

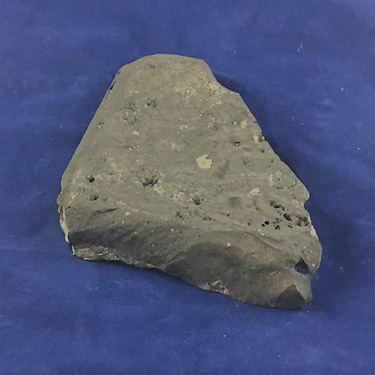

- Broken Slabs

Belmont Product Code 4710 Nominal Composition: - 70% Cu

- 30% Si

-

-

Nickel is known to improve corrosion resistance particularly in sea water. This makes it a good choice to improve the properties of marine alloys. Forms: - 2-14 Mesh Polished Shot

Belmont Product Code 45027 Nominal Composition: - 50% Cu

- 50% Ni

-

-

Zirconium acts as a grain refiner in Copper Alloys and can improve mechanical properties. Forms: - 1" x 6" x 12" Broken Slabs

Belmont Product Code 45046 Nominal Composition: - 50% Cu

- 50% Zr

-

This alloy is used to introduce Titanium into Copper alloys which improves strength. Forms: - 1" x 6" x 12" Slabs

Belmont Product Code 47024 Nominal Composition: - 70% Cu

- 30% Ti

-

A Copper (Cu) Alloy containing Chromium (Cr) used for their high strength and corrosion resistance. It offers high conductivity, good ductivity and strength. Serves as a master alloy to add chrome to various copper alloys. Forms: - 2-20 Ingot

Belmont Product Code 4989 Nominal Composition: - 98.7% Cu

- 1.3% Cr

Technical Info: - CDA #: 81500

- Melting Point (Liquidus): 1985 F, 1085 C

- Melting Point (Solidus): 1967 F, 1075 C

- Density: .319 lb./cu. in. @ 68 F

- Specific Gravity: 8.82

- Thermal Conductivity: 182 Btu./sq. ft./ft./hr/F @ 68 F

- Tensile Strength-ksi: 51

-

Chrome is an addition generally made in Copper Alloys for corrosion resistance and electrical conductivity. Forms: - 2-10 Ingot

Belmont Product Code 4906 Nominal Composition: - 90% Cu

- 10% Cr

-

Magnesium is a strong deoxidizer particularly for nickel alloys. As a Copper master alloy it is effective and less reactive. If alloyed, in can improve mechanical properties. Forms: - Broken Slabs

Belmont Product Code 4800 Nominal Composition: - 80% Cu

- 20% Mg

-

-

A Beryllium containing copper base master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts. Forms: - Approx. 1" Pcs.

- 1/2" and Down Shot

- Slabs

Belmont Product Code 4962 Nominal Composition: - 96% Cu

- 4% Be

RELATED POSTS

Adding Iron into Copper Alloys: Properties and Advantages

Many of the metals used in applications are the combinations of several different types of materials. The reason for this is quite simple. Many pure metals have the unique properties we need in certain types of applications. Such as in the case of copper, this metal offers excellent corrosion resistance in saltwater environments. It also…

Cobalt Applications: Increasing Demand for This Metal Impacting Availability

Cobalt has seen rapid market growth for the past few decades. It has wide ranging uses in a number of applications as prices have skyrocketed for this metal since 2017. With the increase in demand, and its use in certain specific applications, manufacturers have to consider whether they will have enough supplies for their current…

Zirconium: An Alloying Element with Copper Alloys

Copper alloys are widely used metals for manufacturing purposes around the world. From copper pipes, electrical wires, mechanical components and other applications, manufacturers are creating the products for companies to run their operations and for the public to improve their daily lives. This unique alloy offers excellent thermal and electrical capabilities. Other elements will also…

Magnesium and Copper Alloys: Benefits and Applications

Copper is well known for its electrical and thermal conductivity. It’s often used for electrical wiring purposes and electrical contacts for small and large applications. This metal is also considered a very soft material, as its malleability allows it to be worked into wires and cables. To add strength without impacting its ductility, magnesium is…

Oversupply and Slow Demand Creating Fluctuating Cobalt Prices into 2019

When it comes to tools, superalloys, magnets and batteries, cobalt is a key material used in manufacturing products we need in our daily lives. Purchasing this metal at an acceptable price and answering consumer demand can influence a manufacturer’s operations now and in the future. When looking at the price market, there has been drastic…

Alloy Properties: Altering the Composition of Metals

For specific applications, you know that using alloys will be the best choice when you are looking for metals that will provide special properties such as strength, thermal conductivity or corrosion resistance. Yet you may be wondering why you can’t simply use the metal it its original form. For example, why can’t you get the…

The Properties of Boron and How Its Used as an Alloying Agent

Are you looking for high-quality copper boron that can be easily mixed with other metals in order to create custom alloys? If you are, we offer 2 percent boron copper, which is a great degassifier, deoxifier and grain refiner. Boron: Uses and Properties Boron is a non-metallic element located in group 13, period 2, block…

Zirconium: Deoxidation and Corrosion Resistance Properties for Copper

Metals such as copper are very popular in a range of industries including manufacturing, plumbing and construction. However, it can be prone to deformations when hot worked or during machining. The deformations can cause the metal to fail to keep its desired shape and impact its structure, especially during pipe bending processes. Adding zirconium can…

Lithium’s Properties and Alloying Capabilities in Manufacturing Processes

When discussing lithium, most people associate this element to the lithium batteries that are found in computing devices such as laptops, smartphones and tablet devices. Yet lithium is a metal that is used throughout a range of commercial, manufacturing and industrial processes including the aviation and aerospace industries. The Properties of Lithium Lithium is considered…

Magnesium Elements: Providing Positive Benefits to Copper and Aluminum Alloys

Alloys on their own can offer a range of mechanical and structural benefits for manufacturers and other industries. Yet your application may require the alloy to have increased strength, workability, or ductility for the particular application. Magnesium is one of many chemical elements that becomes added to other alloys such as copper and aluminum to…

Silicon: Increasing the Properties of Aluminum and Copper Alloys

Copper and aluminum are used in a range of applications around the world. You can find aluminum as beverage cans, metal building sheets and storage tanks. Copper is often found in environments that are electrically conducive, as you may see it as wiring. You can also find copper in electronics and used as brass or…

Zirconium adding resistance capabilities to copper for an increase in hardness while handling higher temperatures

Name a metal alloy that has been used for centuries, and many people will think of aluminum, iron or copper. Yet Zirconium should also be added to the list. There are numerous products in our workplaces and our homes that uses this silvery-gray metal, such as lamp filaments, television glass, and even in some deodorants….

Lithium Copper Improving Alloy Quality for Better Product Manufacturing

Working with various copper, pure copper and nickel-based alloys allow for manufacturers to create end products for customers and the necessary components for their operations. However, one issue that companies experience is alloy quality during the melting and casting process. When copper and nickel-based alloys are melted, oxygen becomes introduced into the alloys from the…

Deoxidation of Copper Alloys

The deoxidation of copper alloys involves removing the oxygen using a chemical process, usually other metals. As the oxygen and other gases are removed from the metal, certain properties are either enhanced or decreased. For example, when Phosphor is added to bronze alloys, it reacts by removing the oxygen content from the metal which can…

Playing up Beryllium Copper’s strengths

Ensure you get the most out of this red-metal alloy by understanding its unique properties With each new generation of electronics, laptops get slimmer and more powerful and cell phones have even greater capacities for the amount of apps, music, and streaming sports and television that consumers want to carry around with them. All these…

Beyond base metals

Minor metals are major players in high-tech innovation Typically the word “minor” refers to things of lesser importance, size or degree. Minor metals, however, are far from inferior—they are major players in a wide range of specialty, high-tech industries and used to create alloys with desirable mechanical properties, including deformability and corrosion resistance. Minor metals…

The right metal for the job

Custom alloys can help streamline production Although custom alloys often are associated with new and advanced applications, they also can solve real-world production problems. For more than a century, Belmont Metals, based in Brooklyn, New York, has been working collaboratively with its customers to create materials that can improve their manufacturing processes. Coming up with…

Bring out the best

Master alloys help copper shine Red metals have played an important role in many cultures, including those of the ancient Egyptians and Romans, who crafted tools, cookware, dishes, mirrors and razors out of copper. Modern uses for copper include electrical, heating/cooling applications, fluid handling and plumbing applications, as well as an increasing demand for the…

Controlling composition using Master Alloys

Create materials that meet specific needs by adding master alloys to the mix It’s important to choose the right materials for a job. Using inferior or unsuitable materials can make completing a project more difficult or even derail it entirely. In the metals industry, combinations of metals, called alloys, are generated to meet the specific…