Tin-Based Alloys

Anodes: Electroplating

Featuring a wide variety of alloys and shapes for all electroplating processes including INCO Nickel, High Grade Zinc, CDA 101 Copper.

View more

Babbitt Metals

Featuring tin-base and lead-base babbitt to ASTM, SAE, government, Navy specifications; special and custom alloys.

View more

Jackson Wheeler

Featuring Tuftin, Tuftex, Guntex, 4X, Hammer Alloy, Rollite, Duratex and Chipper Alloy

View more

Jewelry Alloys

Featuring: Art Caster’s Brass, Beryllium Copper, Brittania, Electrolytic Copper, Everdur, Jeweler’s Manganese Bronze, Nickel-Silver, Pewters, Superdie Zinc Alloys, and White Bronze

View more

Pewter

Featuring Lead Free Pewter and Lead Free Pewter alloyed with Silver, Indium, and Bismuth, as well as Brittania, and Genuine Pewter

View more

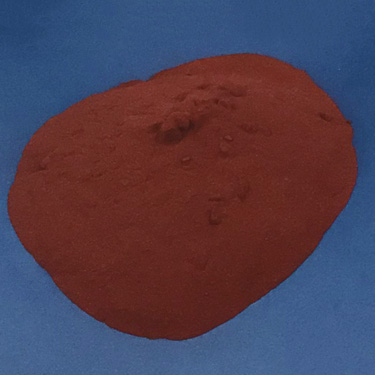

Powdered Metals

Featuring: Holtite Alsil Grit, Iron Powder, High Grade Zinc, Tin, and Copper-Aluminum Applications

View more

Solders

Featuring: Body solders, Lead-base, Lead-free solders, Low melting solders, Miter-Al-braze (MAB), Tin-Antimony solders, Tin-base, Tin-Cadmium solders, Tin-Lead solders, Tin-Zinc solders

View more

Tin Alloys

Featuring: jewelry alloys, Sn anodes for plating, Sn shot for gray iron and titanium alloy additions, Grade A and 99.99% Sn, Sn-base babbitts, 5% phosphor Sn, Pewter, Sn-base solders, Sn powder, Sn oxide powder, Sn granular.

View moreFeatured Products

-

Can be used for various soldering methods including Wave, Selective, and Hand. Known for best in class yields, this material outperforms all Sn/Cu based materials and delivers excellent performance across a wide range of Flux Technologies. SAC305 is used to stabilize the copper content in the wave solder bath depending on process conditions. Forms: - Regular Bar

- Shot

- Ingot

Belmont Product Code 7972 Nominal Composition: - Sn: 96.5%

- Ag: 3%

- Cu: 0.5%

Technical Info: - Solidus: 217 C (423 F)

- Liquidus: 220 C (428 F)

-

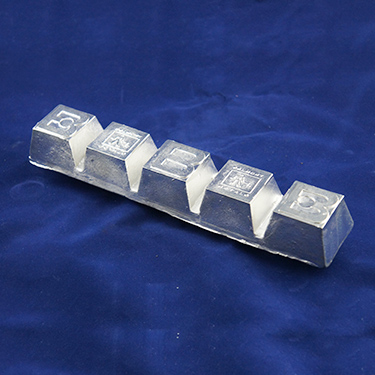

Easily cast White Brass Alloy with good fluidity and high detail. We offer this material in a variety of forms including Ingot, Cut Bars, Cubes and Shot. Forms: - Ingot

- 2" Cut Bar

- 1/2" Polished Cubes

- Shot

Belmont Product Code 45815 Nominal Composition: - Cu: 58%

- Mn: 20%

- Zn: 20%

- Al: 1%

- Pb: 1%

-

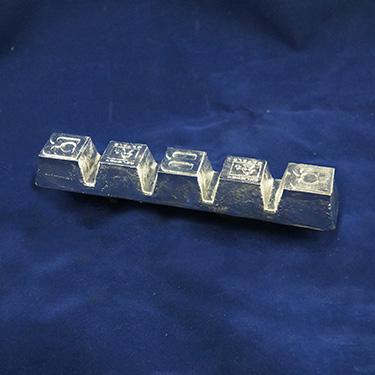

This is our Original, Lead Free, Zinc Based Alloy that works well in Spin Cast Vulcanized Silicone Molds for designs with thick cross sections or minimal detail. Contains Proprietary Grain Refiners for improved casting properties. Forms: - 4-20 lb. KZ Ingot

Belmont Product Code 892NS1 Nominal Composition: - 90-94% Zinc in a Proprietary Formula

Technical Info: - Elongation : 8%

- Liquidus Temperature: 734F

- Pouring Temperatire: 800 F - 875 F

- Density: .244 lbs / Cu. In.

- Tensile Strength: 54,000

- Compression Strength: 68,800 psi

- Brinell Hardness: 146

- Finishes: Mechanical, chemical, organic, and electro-deposited, plastic

-

This Solder has good corrosion resistance and tensile strength. With a melting range beginning at 390 Deg. F. it avoids causing damage to critical electronics as well preventing substrate deformation and segregation. It is used very often in spray wire form for capacitors and other electronic parts. Forms: - 1/16" Dia. Plus .000" Minus .004" on 5 Lb. Spools

- 2-5 Ingot

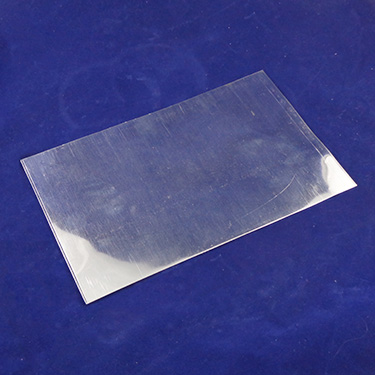

- Cast Flat Anodes

Belmont Product Code 7601DS1C Nominal Composition: - 60.5% Sn

- 39.5% Zn

-

Tin-Lead solders is the largest single group and the most widely used of the soldering alloys . Tin-Lead solders are compatible for use with all types of base metal cleaners, fluxes, and heating methods. 60/40 Tin Lead solder, almost the eutectic is particularly adaptable to delicate work or when soldering temperature may be critical. This particular item comes in 1/16" Diameter and can also be offered in other sizes as well. This is also a quick setting solder for fine electrical and tinsmith work. Forms: - 1/16" Dia. Solid Wire

Belmont Product Code 76001DSC Nominal Composition: - 60% Sn

- 40% Pb

-

Lead Silver solders such as this have physical properties - tensile, creep, and shear strength - which are good to 350 Deg. F. Fatigue properties are also better than the non silver solder alloys. Forms: - .063 Dia. Solid Wire

- 5Lb. Spools

- Capping Bars

Belmont Product Code 5951DS1C Nominal Composition: - 60% Sn

- 40% Pb

- 5.5% Ag

-

This is a Bismuth based non-eutectic alloy commonly used as a low-melting solder and also to make custom shaped blocks. It is also used to make metal inlays in wood and also useful for repairing antiques as the low melting temperature of Wood's metal makes it unlikely this will harm the original piece. Forms: - 1/4" Dia. Solid Wire

- 1/8" Dia Solid Wire

Belmont Product Code 2502DS1C Nominal Composition: - 12.5% Sn

- 25% Pb

- 50% Bi

- 12.5% Cd

-

-

-

-

Forms: - 5-6 Ingot

- 1/4" and Down Unpolished Irregular Shot

- .05" Dia. Solid Wire 1 Lb. Spools

Belmont Product Code 7921 Nominal Composition: - 91.75% Sn

- 8% Sb

- 0.25% Cu

Technical Info: - Elongation (2" Section) : 20% - 40%

- Liquidus Temperature: 465F - 485F

- Solidus Temperature: 515F - 635F

- Density: .23 - .275 lb. / Cu. In. @ 68F

- Brinell: 18 - 25

- Tensile Strength: 5,000 psi - 8700 psi

- Solderability: Can be soldered Easily with soft solder and flux

- Finishes: Mechanical, chemical, organic, and electroplated

-

Belmont Special 92% Tin Pewter alloy is an excellent casting alloy with approximately 92% Tin (Tin base alloy). Special Pewter for figurines, models, etc. with heavy sections - better casting characteristics than lead free Britannia. Forms: - 5-6 Ingot

Belmont Product Code 7924 Nominal Composition: - 92% Sn

- 4% Pb

- 4% Sb

-

35% Tin Pewter, Lead, Tin Alloy easy meltable with relatively low melting temperature. Offers opportunity for cost savings where its relatively high weight is not a problem . Offers opportunity for cost savings where its relatively high weight is not a problem. Forms: - 5-8 Ingot

Belmont Product Code 5632 Nominal Composition: - 62% Pb

- 3% Sb

- 35% Sn

-

A Proprietary Tin Base Lead Free Alloy with high tensile strength for heavy load applications. Belmont Product Code NV8 Nominal Composition: - Proprietary

-

A Proprietary Tin Base Alloy for medium load application. Belmont Product Code W1 Nominal Composition: - Proprietary

-

A Proprietary Tin Base Babbitt similar to ASTM B23 Grade 2 Babbitt with additions for added strength. Belmont Product Code F10 Nominal Composition: - Proprietary

-

A Prorietary Lead Base Babbitt for low speed applications. Belmont Product Code L2 Nominal Composition: - Proprietary

-

A Proprietary Tin Base Babbitt Alloy with Nickel additions for added strength. Belmont Product Code E5 Nominal Composition: - Proprietary

-

A Proprietary Lead Base Babbitt often used in the relining of bearings in elevators. Belmont Product Code P1 Nominal Composition: - Proprietary

-

-

A Proprietary Lead Base Babbitt with high compression, strength, and excellent heat transfer. Belmont Product Code B3 Nominal Composition: - Proprietary

-

A Proprietary Lead Base in the manufacture of wood chipper knives. Belmont Product Code C3 Nominal Composition: - Proprietary

-

A Proprietary Tin Base Alloy used for high speed high load applications. Belmont Product Code D3 Nominal Composition: - Proprietary

-

A Proprietary Lead Base Alloy with a small addition of Nickel for additional hardness. Belmont Product Code J1 Nominal Composition: - Proprietary

-

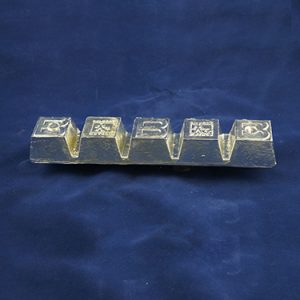

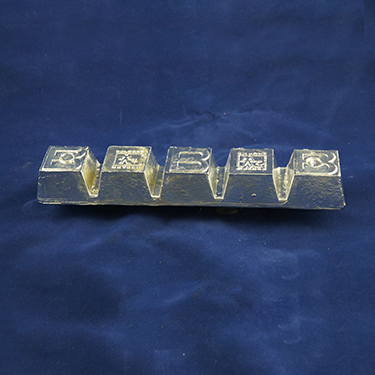

Phosphorus is used in tin as in tin solders to suppress dross formation keeping the metal bath cleaner. Forms: - Waffle

Belmont Product Code 7955 Nominal Composition: - 95% Sn

- 5% P

-

-

-

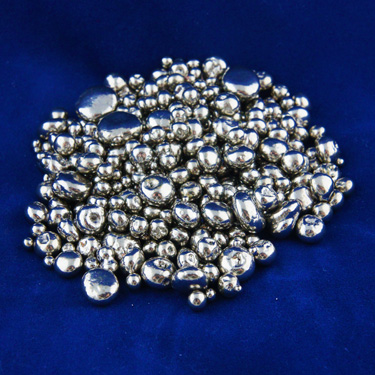

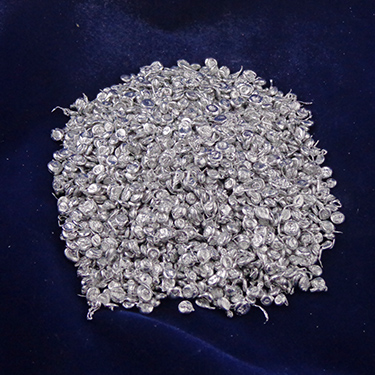

Nickel is known to improve corrosion resistance particularly in sea water. This makes it a good choice to improve the properties of marine alloys. Forms: - 2-14 Mesh Polished Shot

Belmont Product Code 45027 Nominal Composition: - 50% Cu

- 50% Ni

-

Master Alloy used in the production of Copper Alloys for a wide variety of industries. The introduction of Boron to Copper Alloys helps eliminate gas and porosity without the loss of conductivity. Forms: - 1/2" and Down Polished Shot

Belmont Product Code 49817 Nominal Composition: - 98% Cu

- 2% B

-

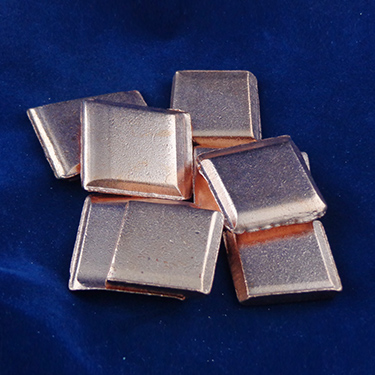

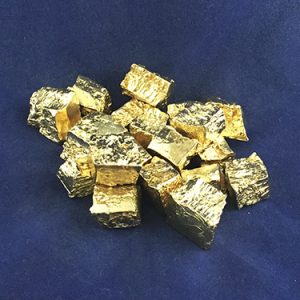

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - Cast Flat Top Anode Approx 1-1/4" Each

- 1" x 1" x 1" Nuggets

Belmont Product Code 48012A Nominal Composition: - 20% Zn

- 80% Cu

Technical Info: - CDA #: 87300

-

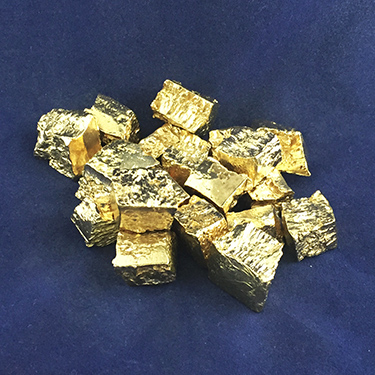

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - 1" x 1" x 1" Nuggets

- Cast Flat Top Anode Approx 1-1/4" Each

Belmont Product Code 47018A Nominal Composition: - 30% Zn

- 70% Cu

Technical Info: - CDA #: 96400

-

Mainly used in galvanizing steel to prevent rusting, in zinc die casting alloys and in copper based alloys, such as brass. Zinc is also essential to the growth of many kinds of organisms, both plant and animal. Zinc also extends the life of other material such as steel (by hot dipping or electrogalvanizing), rubber and plastics (as an aging inhibitor) and wood (in paints). Forms: - Flat Tops

Belmont Product Code 8000AM Nominal Composition: - 99.99% Zn

-

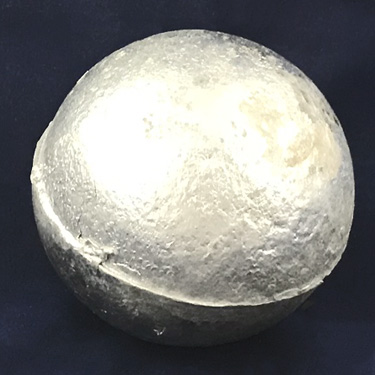

Zinc metal coatings provide better protection on Iron and Steel than any other corrosion resistant coatings. Plated SHG Zinc coatings are pure compared to hot dipped and are also thinner and more ductile, which allows them to be made brighter and more lustrous. We offer this material in 2" diameter balls that are solid and clean and do not have any flash orgates which would cause backet hang ups. Forms: - 2" Diameter Balls

Belmont Product Code 8000AG Nominal Composition: - 99.99% Zn