When Baron Cronstedt originally extracted nickel in 1751, he intended to produce copper. That’s why he called this newly discovered metal kupfernickel, a German word that roughly translates in English to “devil’s copper.” Even though nickel’s a very useful and popular metal, the name might almost appear ironic to some people in modern times. Though…

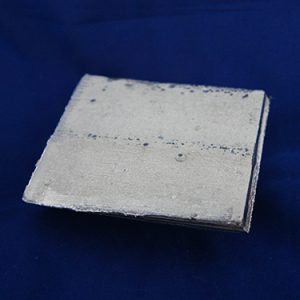

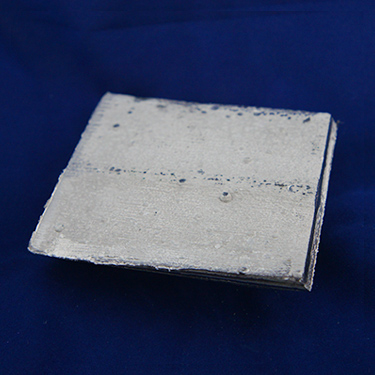

Featuring VALE, 99.9% Electrolytic Ni for gold alloying, and plating, and Ni shot for foundries.

Nickel was used by ancient man in swords and implements fashioned by from nickel-bearing meteorites and in coins made from pakton, a nickel-copper alloy first developed in China. It was extracted as an element in 1751 and named Nickel from the ore “kupfer-nickel”, so-called by superstitious miners who believed that the ore was bedeviled. The modern nickel industry dates from the opening of the New Caledonia mines in 1875 and those of Sudbury, Ontario, in 1886. Today, roughly 1 million tons of primary Nickel is produced and consumed annually in the world.

Nickel has a vast number of uses throughout industry. The most commonly known use must be in coins when alloyed with copper, and in stainless steel when alloyed with iron and chromium. It is used in metallic and salt form with and without other metals and salts, as a catalyst in a large range of inorganic chemical reactions. Many types of steel alloys contain nickel especially when resistance to corrosion is required. It is used for plating, especially in the automotive industry and for cutlery. Some types of batteries use nickel. It forms part of many high strength alloys used in the aeronautics industry.

Read More

Showing all 7 results

Featured products

RELATED POSTS

Gold Karat Alloying: Adding Master Alloys and Virgin Additives to Enhance Characteristics

The beauty and rarity of gold is well-known. It’s treasured by jewelers due to its brilliant color and historians who are in search of antique coins. For everyday applications, gold is found throughout our lives in smart phones, laptops and other electronics as this metal is crafted into gold-plated circuit boards. Applications will use gold…