For jewelry casting, manufacturers have a wide range of base metals and alloys to select from for their pieces. Most common metals that consumers are familiar with are gold, silver, platinum, and sterling silver. Yet there are many other types of alloys that may be used, including tin and zinc. When determining which alloy to…

RELATED POSTS

Manufacturing Benefits of Pure Tin in Shot & Granular Form

When evaluating metals used to strengthen other alloys and to provide unique mechanical and physical properties, tin in higher purities is one metal that manufacturers take a close look at. Tin is an abundant metal as it is used in a number of manufacturing purposes and industries. This metal is often used as an outer…

Benefits of Alloying Ag with Sn Alloys

While tin (Sn) is not mentioned as often as copper, it is another widely used metal for industrial applications. Tin is used most in electroplating, where the metal is used to coat other base metals to provide protection from other factors such as corrosion. Electroplating can also provide a more aesthetically pleasing appearance. The tin…

Different Grades of Tin

Tin is used through the world in a range of different applications. It is commonly used as coatings on other metals, such as steel sheets that are manufactured into beverage cans and other food containers. This metal is also found in ornamental products as well as costume jewelry. Tin can be alloyed to other base…

Shot and Cubed Alloys: Advantages of Using Different Shaped Metals

Due to advanced manufacturing processes, companies today can use a range of base metals and alloys to create the right products and components to their industries. When obtaining the metals that will be used in casting, extruding and forming processes, manufacturers can request the alloys and base metals in various sizes and shapes. Ingots, cubes,…

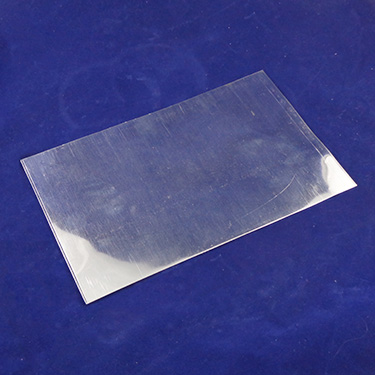

Applications and Uses for Tin Sheet

Tin has been around for thousands of years and was most commonly used for the manufacturing of bronze, which is a tin and copper alloy. Today, most people would associate tin with the tin can found on grocery store shelves. However, tin and its alloys are used for far more than the making of bronze…

Selecting the Appropriate Babbitt Alloy

Babbitt metals are either lead or tin based, and the metal makes excellent bearings that are easy to pour as a DIY project. However, before you pour your bearings, you must select the correct babbitt metal in order to ensure your engine or piece of machinery operates correctly and efficiently. If you know the composition…

Antimony: Possessing Durability and Versatility When Alloyed with Other Metals

Semiconductors, machine bearings, and utensils are all made from varying amounts of metal alloys. Yet these items also possess one common factor: antimony. Antimony is a semi-metal element that comes in both a powdered form as well as a hard and brittle metal. Possessing a silvery, blush white appearance, this element is highly desired when…

Chemical reactions

ACS Reagent-grade Tin and Zinc for use in chemical analysis and compound creation Tin and Zinc are essential components of many alloys, but uses for these two elements extend beyond solders, die castings, galvanizing, and plating. Reagent grades of Zinc and Tin can be used in chemical analysis or other reactions. In organic chemistry, reagents…

Keep on rolling

Babbitt metals ensure machinery runs smoothly Bearings play an integral role in machine efficiency by reducing friction between moving parts. The earliest recorded examples of bearing usage date back to the Romans, and in the year 1500, Leonardo da Vinci sketched a design for a helicopter that incorporated ball bearings. Today, common types of bearings…

Safe sparklers

Using lead-free pewter alloys for making jewelry helps alleviate health concerns Adding lead to an alloy can help create characteristics—such as softness and lower melting temperatures—that are useful for many applications. However, lead also is a neurotoxin that is dangerous to animals and humans. Small children are more vulnerable to the effects of lead exposure…