Bronze and brass are both copper alloys, but they solve different problems. One excels at reducing friction, while the other is ideal for applications requiring high levels of conductivity. They also differ in corrosion resistance, wear, machining time, and cost. Understanding how each metal performs under various service conditions can help you meet performance targets…

RELATED POSTS

A Potential Forecast for the Copper Market in 2022

For the last several months, metal markets have remained tough to predict because of the pandemic’s various impacts on demand and supply and the overall economic climate. Still, prudent businesses must base forecasts upon the best information they have available. Take a look at this year’s copper market and business developments to gain perspective on…

Why Companies Are Switching from Lead to Bismuth for Copper and Tin Alloys

Are you looking for an alternative to lead-based alloys? Many companies are moving away from lead and copper and tin alloys due to the regulations and toxicity associated with the heavy metal, and that often means choosing bismuth. The good news is that bismuth has a relatively low melting point, and it’s durable and malleable…

Understanding the Various Metals Used for Plating

Are you considering plating metals? The process of metal plating is performed to improve corrosion resistance, add aesthetic appeal, enhance the metal’s hardness, reduce friction in moving pieces, increase or decrease conductivity and to improve solderability. The most common plating metals include brass, bronze, cadmium, nickel and tin, and here at Belmont Metals, we sell…

A Brief Guide to Understanding the Electroplating Process

Electroplating refers to a process used to bind a layer of one metal over the surface of another one. Electroplating changes the properties of an item’s surface, providing protection, improving its appearance, or very often, both. Besides creating a protective coating for a metal item, manufacturers also might use electroplating to increase its thickness or…

Different Grades of Copper

Copper is a commercial metal that is used throughout the world due to its mechanical and structural properties. This metal offers excellent thermal and electrical conductivity. Also, it resists corrosion as its malleability and ductility allows the metal to be easily worked and fabricated. There are different grades of metal based on its purity levels….

Copper Preventing Future Pandemics? Research Study Evaluates the Metal’s Anti-Microbial Properties

When working with commercial and industrial manufacturing operations, many companies use specific metals in their applications due to their inherent capabilities. One of the most common metals used is copper, as Belmont Metals offers copper metal, copper alloys, and copper-master alloys such as beryllium copper, lithium copper and zirconium copper to manufacturers, jewelers, artists, and…

Electroplating Advantages: Using Different Coating Products to Provide Enhanced Benefits

You would be surprised just how many items in our lives have electroplating. From your car when driving to work to the jewelry worn on special occasions, commercial manufacturing processes rely on this process to protect metals, as well as plastics, by coating them with an exterior layer of metal. While the most well-known reason…

What is electroplating?

Electroplating refers to a process that adds a surface layer of metal to another type of metal. It’s typically used to prevent corrosion and rust and to extend the useful life of the metal underneath the electroplated metal. Of course, it’s also used to make gold and silver plated jewelry and knickknacks and to give…

Gold Karat Alloying: Adding Master Alloys and Virgin Additives to Enhance Characteristics

The beauty and rarity of gold is well-known. It’s treasured by jewelers due to its brilliant color and historians who are in search of antique coins. For everyday applications, gold is found throughout our lives in smart phones, laptops and other electronics as this metal is crafted into gold-plated circuit boards. Applications will use gold…

Electroplating with Tin Anodes: Uses and Examples

Machinery used in manufacturing applications can consist of a range of metals and alloys that provide strength, electrical and thermal conductivity, durability, workability and other characteristics. However, the metal part itself could be detrimentally impacted by the environment and the working application itself. In other instances, the metal part could create problems if it comes…

Alloy Impurities: Trace Elements Changing the Characteristics of Copper

Throughout industrial and manufacturing operations, you’ll find copper metals used in both equipment and finished products. Pure copper has incredible thermal and conducive properties. It also provides exceptional corrosion resistance. So you’ll often find it in electrical applications and electronic products. In addition, pure copper is very soft and malleable, making it ideal for numerous…

Choosing an Alloy to Get the Best Application Results

Brass and bronze are used in a range of applications, such as component parts for factories, end products for commercial retailers, and creating jewelry for the public. Brass alloys consist of the base metal of copper with varying amounts of zinc added, while bronze contains copper with aluminum, tin, magnesium and other materials. Yet how…

Water safety

Lead-free and low-lead alloys keep up with plumbing industry regulations Copper faucets, sinks and appliances have a lustrous color that helps create a warm atmosphere, making a house feel like a home. Copper and its alloys also are functional and durable. They resist corrosion and require little maintenance, which makes red metals an ideal choice…

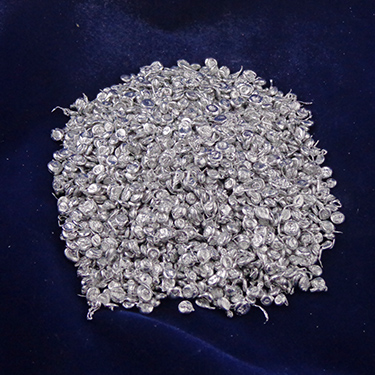

Bring out the best

Master alloys help copper shine Red metals have played an important role in many cultures, including those of the ancient Egyptians and Romans, who crafted tools, cookware, dishes, mirrors and razors out of copper. Modern uses for copper include electrical, heating/cooling applications, fluid handling and plumbing applications, as well as an increasing demand for the…