Showing all 39 results

Featured products

-

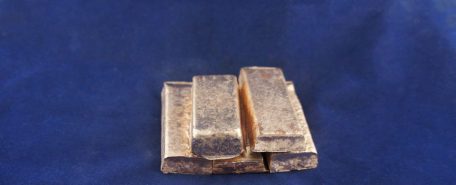

Copper Silver alloys in varying compositions have become increasingly popular in the use of producing diamond impregnated bits due to increased infiltration rates and wearability which improves product performance depending on the drilling requirements. Custom compositions are available upon request. Forms: - 1/2" & Down Polished Shot

- Ingot

Belmont Product Code 48024 Nominal Composition: - Proprietary

-

Can be considered either a deoxidizer or grain refiner. Generally, for pure copper its role would be deoxidizing but in brasses it’s more of a grain refiner. Forms: - 3/4" & Down Polished Shot

- 3/4" & Down Unpolished Shot

- 40-15 Waffle

- 4-5 Oz Pcs.

Belmont Product Code 4987 Nominal Composition: - 98% Cu

- 2% B

-

Forms: - 5-6 Ingot

- 1/4" and Down Unpolished Irregular Shot

- .05" Dia. Solid Wire 1 Lb. Spools

Belmont Product Code 7921 Nominal Composition: - 91.75% Sn

- 8% Sb

- 0.25% Cu

Technical Info: - Elongation (2" Section) : 20% - 40%

- Liquidus Temperature: 465F - 485F

- Solidus Temperature: 515F - 635F

- Density: .23 - .275 lb. / Cu. In. @ 68F

- Brinell: 18 - 25

- Tensile Strength: 5,000 psi - 8700 psi

- Solderability: Can be soldered Easily with soft solder and flux

- Finishes: Mechanical, chemical, organic, and electroplated

-

Master Alloy used in the production of Copper Alloys for a wide variety of industries. The introduction of Boron to Copper Alloys helps eliminate gas and porosity without the loss of conductivity. Forms: - 1/2" and Down Polished Shot

Belmont Product Code 49817 Nominal Composition: - 98% Cu

- 2% B

-

Phos Copper is the most commonly used deoxidizer. Effectively removes oxygen from molten metal with little or no reaction or dross formation. Forms: - 3 Mesh Shot

- Approx. 15 Lb. Waffle Ingots

Belmont Product Code 48514 Nominal Composition: - 85% Cu

- 15% P

-

-

Nickel is known to improve corrosion resistance particularly in sea water. This makes it a good choice to improve the properties of marine alloys. Forms: - 2-14 Mesh Polished Shot

Belmont Product Code 45027 Nominal Composition: - 50% Cu

- 50% Ni

-

-

A Beryllium containing copper base master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts. Forms: - Approx. 1" Pcs.

- 1/2" and Down Shot

- Slabs

Belmont Product Code 4962 Nominal Composition: - 96% Cu

- 4% Be

-

Linotype shot for hydrometals and bullet casting. It is good for varmit cast bullets. Linotype does not have a larger % of tin in it but it really has a larger percentage of antimony that makes for hard and brittle bullets. Forms: - 10-20 Mesh .078" x .033"

Belmont Product Code 58410 Nominal Composition: - 84.25% Pb

- 11.5% Sb

- 4.25% Sn

-

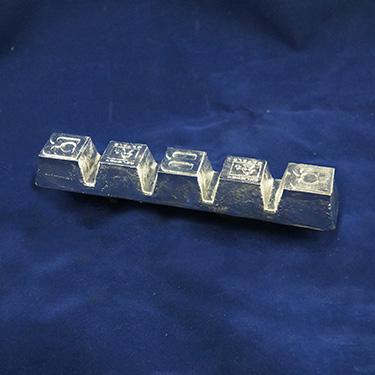

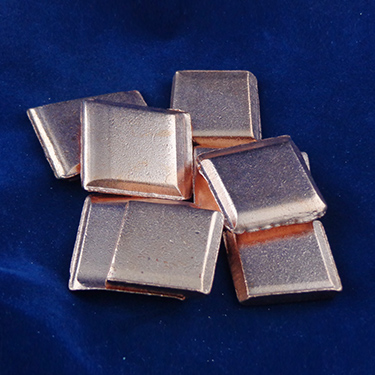

Bell metal is a hard alloy used for making bells and related instruments, such as cymbals. It is a form of bronze with a higher tin content, usually in approximately a 4:1 ratio of copper to tin (typically, 78% copper, 22% tin by mass). We offer this material in Ingot, shot, and cut pieces. Forms: - Ingot

- Irregular Shot

- 1/2" Polished Cubes

- 2" Cut Pieces

Belmont Product Code 4788 Nominal Composition: - Cu: 78%

- Sn: 22%

-

This alloy offers high strength, hardness, wear resistance with excellent fluidity. This alloy is ideal for investment, sand or ceramic casting and provides excellent replication of intricate detail. Forms: - 2-5 Ingot

- 2" Cut Bars

- 1" Cut Bar

- 1/2" Polished Cubes

- 1/2" x 14 Mesh Shot

Belmont Product Code 4977 Nominal Composition: - 97.2% Cu, 2.05% Be, 0.5% Co, 0.25% Si

-

This material offers the highest strength and hardness of all the BeCu alloys with excellent wear resistance and fluidity. Also offers extremely fine detail pick-up in ceramic or pressure cast processes. This also has the lowest pouring temperature of the BeCu alloys allowing almost any type of molding process to be used. Forms: - 1/2" and Down Polished Shot

- 1/2" X 14 Mesh Unpolished Shot

- 2-5 Ingot

Belmont Product Code 4971 Nominal Composition: - 96.43% Cu

- 2.7% Be

- 0.5% Co

- 0.3% Si

- 0.07% Ti

-

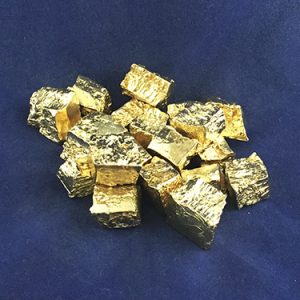

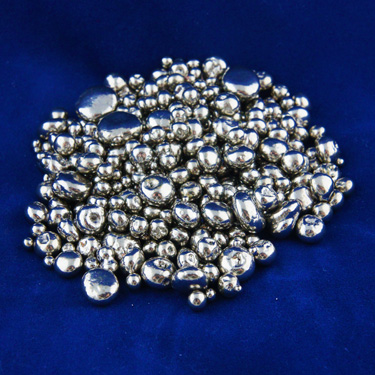

Lead base alloy for casting bullets and fishing jigs. Linotype will have a brinell hardness and good strength. Used to be used a lot in the printing industry. Forms: - 10-20 Mesh 0.078" x 0.033

- 12-30 Mesh .0661 in. - .032"

- 20-25 Lb. Pig

- 40 Lb. Pigs

- Approx. 40 Lb. Pigs

Belmont Product Code 5841 Nominal Composition: - 84% Pb

- 12% Sb

- 4% Sn

-

This is a Bismuth based eutectic alloy which finds uses in shielding during medical radiation treatments and is also a cadmium-free solution for radiation therapy. This material also has a rapid growth of up to .0061 after casting. It has also been used as anchoring material and for designing fusible links. Forms: - Cakes

- 1/8", 1/32" Dia. Solid Wire

- Irregular Shot

- Pigs

Belmont Product Code 2531 Nominal Composition: - 52.5% Bi

- 32% Pb

- 15.5% Sn

Technical Info: - Melting Point - Solidus 203 F, 95 C

- Melting Point - Liquidus 203 F, 95 C

- Short-Term Tensile Strength lbs/sq.in. 6100

- Yield Temperature 203

- Weight lbs/cu.in 0.35

- Brinnell Hardness No. (500 kg) 9

- Growth/Shrinkage - Time after Casting: after 2 mi.: -0.0002

- after 1 hour: 0.0055

- after 24 hrs: 0.0057

- after 500 hrs: 0.0061

-

R-8-18 size 0.18" Diameter, but tend to vary in size. It is used for a variety of other purposes with dense material for weight/balance. Due to lead's high desity, it is used to attenuate radiation, especially X-rays. Lead shot may be enclosed in a bag and then placed around a point source for radiation protection or for radiation shielding. Forms: - 8-16 Mesh Shot

Belmont Product Code 5011 Nominal Composition: - 99.90 Pb

-

Lead shot is available for different applications. Type BB Lead shot prepare for ammunition measure 0.18 inches in diameter. Lead is the most common material for shotgun. Forms: - 0.18" Dia

Belmont Product Code 5010 Nominal Composition: - 99.90% Pb