Craftspeople have been casting with bronze for so long that the BBC called it the “first alloy.” Introduced around 3,500 BC and typically made with mostly copper and tin, items made with bronze offered a more durable alternative to coper alone. Artifacts from brass have been dated to 500 BC. Brass may have been favored over bronze for some artwork and other items because of its more golden appearance and high malleability.

In comparison to brass and bronze, silicon hasn’t been used or blended with other alloys for very long at all. As metal-cast artists, you’re probably familiar with some basic facts about various alloys. Still, you may have some questions about how silicon bronze and silicon brass compare to each other and to traditional alloys.

Silicon Brass Vs. Silicon Bronze in Art Casting Applications

Before discussing silicon brass and bronze, it’s helpful to review these alloys’ similarities and differences. Both brass and bronze are called copper alloys. The combination of copper and zinc gives brass its unique qualities, such as the ability to flow easily for casting and its relative softness and malleability. Bronze, on the other hand, comes mainly from copper and tin. Its harder than brass but also somewhat brittle and not as flexible.

For instance, house keys are generally made from brass and not bronze because brass is soft enough for cutting with inexpensive tools. Though artists use both brass and bronze for sculptures, jewelry, and other works of art, you will see typically see more intricate designs made from brass than bronze. On the other hand, the ancients typically crafted tools from harder bronze and not softer brass.

How Silicon Changes Bronze and Brass

Silicone is abundant, inexpensive, and non-toxic. It can also change the characteristics of copper alloys when compared to materials made without silicon. For some applications, such as art casting, adding silicon to copper alloys can improve both the process and the results.

Silicon Brass

Some advantages of silicon brass over typical brass are:

- Better corrosion resistance

- Lower conductivity

- Improves strength and is considered a high-strength brass

Silicon Bronze

Benefits of using silicon bronze over typical bronze include:

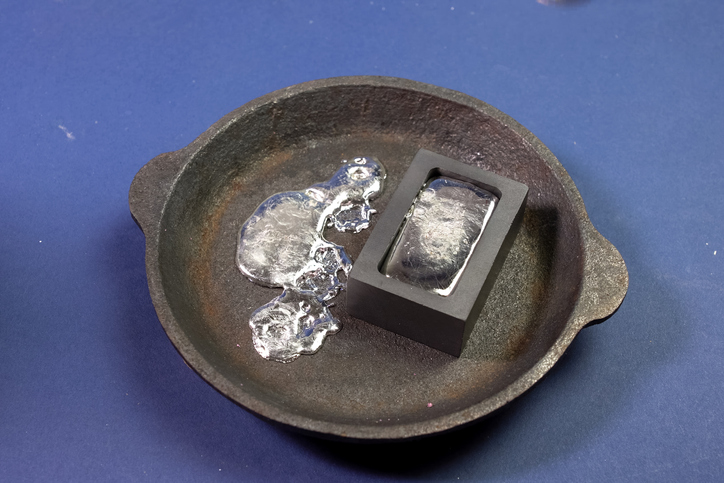

- More fluidity during casting

- Less brittle

- Reduced contraction when cooling

All Copper Alloys

For all copper alloys, silicon also helps deoxygenate the material. This benefit helps lower the chance of having gas bubbles form and helps reduce brittleness and improve strength. Silicon also has some self-lubricating properties, which may make it ideal for applications that need connections or fixtures. It also reduces the melting temperature of either alloy. Though brass and bronze are both considered resistant to corrosion, silicon can improve this characteristic even more.

Simply put, silicon can reduce some perceived drawbacks of using either of these materials in a more traditional form. At the same time, it can offer additional benefits that make the silicon version of these copper alloys a better choice. For instance, silicon brass is stronger than traditional brass, and silicon bronze is less brittle than a typical bronze alloy.

Buy Silicon Bronze and Silicon Brass for Art Casting Applications

Silicon brass and silicon bronze may offer you benefits that will help you achieve your artistic vision in a way that typical copper alloys won’t. Because of silicon’s abundance, these two metals may also provide you with cost-effective alternatives to other copper alloys.

Located in Brooklyn, NY, Belmont offers a wide selection of copper alloys, including both silicon brass and silicon bronze. Purchasers can choose from a variety of forms and from small to large quantities. Order today, or call or email your questions about these alloys and other metals.