Showing all 22 results

Featured products

-

Bismuth is a white, brittle metal with a slight pink color and is typically recovered as a by-product of lead and copper. It is commonly used as an alloying element for various low melting alloys where it is mixed with other metals such as Lead, Tin, or Cadmium. It is also used as well for a lead substitute in other materials. The Ingots are our largest size available and have a purity of 99.99% and often serve as grain refiner in the foundry industry as well. Our regular bars can be used in solder applications as a replacement for Lead since it is non-toxic. Our 1/8" & down shot product allows you to make smaller additions during your casting process and has a purity of 99.9%. Forms: - Slabs

- #6 Small Shot Approx. 1/8" and Down

- Regular Bar 1/2" X 7/8" X 13"

Belmont Product Code 2001 Nominal Composition: - 99.99% Bi

-

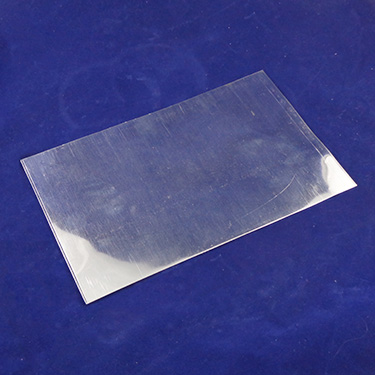

Our standard Grade A Tin is sourced from highest quality supplier and is certified conflict free. We offer this material in a wide variety of forms so we can tailor the metal for your needs. Forms: - Granular

- Pigs

- Approx. 1 Lb. Regular Bars

- Sheet

- Cast Flat Anodes

- 1/4# Capping Bar

- Wire

- 2-5 Ingot

- 8-20 Mesh Shot

- Slabs

Belmont Product Code 7001 Nominal Composition: - 99.85 Sn

- Bal

-

We offer Ultra Pure Tin that is used for specific applications where higher grades are required. Our grade is refined to the highest standards. Ultra Pure Tin has extremely low levels of lead, cadmium, antimony, and copper. And we offer this material in a variety of forms that we can tailor to your application. Forms: - 8-20 Mesh Shot

- Approx. 1 Lb. Bars

- Approx. 53 Lb. Pigs

- Approx. 5 Lb. Ingots

Belmont Product Code 7004 Nominal Composition: - 99.99% Sn

- Bal

-

Excellent general use Bronze for most any Jewelry Applications. This alloy offers very high detail, easy castability, and accepts patinas very well. This alloy has a very warm bronze color. Forms: - 2-20 Ingot

- 2-5 Ingot

- 1/2" & Down Polished Shot

- 1/2" & Down Cubes

- 2" Polished Cut Bar

- Slabs

- Unpolished Shot 1/2" x 14 Mesh

Belmont Product Code 4951 Nominal Composition: - 95% Cu

- 4% Si

- 1% Mn

Technical Info: - CDA #: 87300

- Melting Range: 1550 F - 1780 F, 840 C - 971 C

- Pouring Range: 1900 F - 2250 F, 1010 C - 1235 C

- Density: 0.302 lbs/cu. in, 8.36 g/cu. cm

- Tensile Strength: 55000 lbs/sq. in.

- Yield Strength: 25000 lbs/sq in.

- Brinell Hardness: 85

-

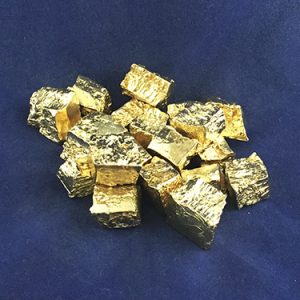

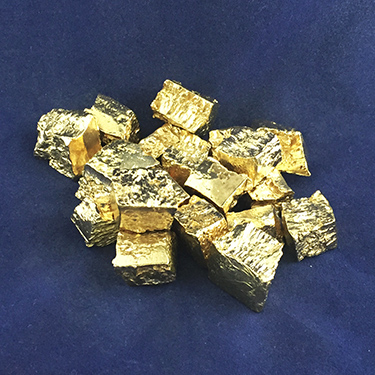

This is a proprietary alloy especially developed for Jewelry casting. This alloy has a warm yellow color. Forms: - 1/2" Polished Cubes

- 1/2" x 14 Mesh Unpolished Shot

- 1" Cut Bar

- 2" Cut Bars

- 2-20 Ingot

- 2-5 Ingot

- Slabs

Belmont Product Code 46316 Nominal Composition: - Proprietary

Technical Info: - Melting Range: 1625 - 1650 F

- Pouring Range: 1700 - 1900 F

- Density: 0.30 lbs per cubic inch

- Specific Gravity: 8.4

- Pattern Makers Shrinkage: 3/16" per foot

- Machinability vs. free cutting brass: 80%

-

Belmont Special "H" Silicon Bronze Alloy has gained increased popularity in recent years with art and jewelry casters, primarily because of its excellent fluidity, low-drossing tendency, sharp detail reproduction, minimal finishing requirements, high ductility and suitable as a cost-effective alternative to tin bronzes. Forms: - 1/2" x 14 Mesh Polished Shot

- 1/2" X 14 Mesh Unpolished Shot

- 1/2" Polished Cubes

- 2" Cut Bars

- 2-20 Ingot

- 2-5 Ingot

Belmont Product Code 4939 Nominal Composition: - 92% Cu

- 4% Si

- 4% Zn

-

-

This alloy offers a white color that is similar to White Gold Alloys and Stainless Steel Alloys. Often used for larger pieces such as belt buckles and larger jewelry pieces. Forms: - 1/2" Polished Cubes

- 1/2" x 14 Mesh Unpolished Shot

- 2" Cut Bars

- 2-20 Ingot

- 2-5 Ingot

- Slabs

Belmont Product Code 4587 Nominal Composition: - Proprietary

-

Lead has been commonly used for thousands of years because it is widespread, easy to extract and easy to work with since it is highly malleable as well as easy to smelt. Lead is used in lead-acid batteries, bullet and shot, weights, and Bricks for Radiation Protection. Forms: - Ingot

- 0.08", 0.09", 0.11", 0.15" Shot

- Pigs

- Capping Bar

- 1 lb Bar

- Powder

- Sheet

- Wool

Belmont Product Code 5002 Nominal Composition: - 99.9% Pb

- Bal

-

Tin-Lead solders is the largest single group and the most widely used of the soldering alloys . Tin-Lead solders are compatible for use with all types of base metal cleaners, fluxes, and heating methods. 60/40 Tin Lead solder, almost the eutectic is particularly adaptable to delicate work or when soldering temperature may be critical. This particular item is a soldering bar weighing approx. 1 Lb. with dimensions of approx. 3/4" wide x 1/4" thick x 14" long. Forms: - 1" Pcs.

- 1/8" & Down Shot

- Capping Bars

- Regular Bar

Belmont Product Code 76015 Nominal Composition: - 60% Sn

- 40% Pb

-

Solders such as this can be used to join copper and most copper alloys, lead, nickel alloys and steel. This general purpose solder has a wide melting range used for automotive, radiator, gutter repair and electrical applications. Can also be offer in various wire diameters as well. Forms: - Regular Bar

- Capping Bar

Belmont Product Code 75012 Nominal Composition: - 50% Sn

- 49.65% Pb

- Bal

-

This solder is primarily used for soldering Aluminum to Aluminum or Copper usually where lower soldering temperature than Zinc-Aluminum solders is required. It is used extensively in spray wire from for capacitors and other electronic parts and also has a high tensile strength. Forms: - 1/4" LB. Capping Bar

- 2-8 Ingot

- 2MM Dia. (.078" - .079") Wire

Belmont Product Code 7702 Nominal Composition: - 70% Sn

- 30% Zn

-

99.99% Pure Indium Shot it is most notably used in the semiconductor industry, in low melting-point metal alloys such as solders, soft metal high vacuum seals and in the production of transparent conductive coatings. Forms: - Ingot

- 1/4" and Down Shot

- Wire

- Bars

Belmont Product Code IN99AAA Nominal Composition: - 99.99% In

- Bal

-

This is a Bismuth based Eutectic low melting alloy used very often to bend tubes and rolled or extruded shapes. This alloy which is normally used for tubes up to 2-1/2" Diameter allows them to be bent or formed to the desired shape without any kinks. Without using this material the tubes or shapes may kink or bend irregularly. It can also be used for work-holding, fusible safety devices and low temperature soldering. Forms: - Cakes

- Capping Bars

- 1/8" & Down Shot

- .05", 1/8", 3/32" Dia Solid Wire

- 1/8" x 18" Cast Strips

Belmont Product Code 2505 Nominal Composition: - 50% Bi

- 10% Cd

- 26.7% Pb

- 13.3% Sn

Technical Info: - Melting Point - Solidus 158 F, 70 C

- Melting Point - Liquidus 158 F, 70 C

- Short-Term Tensile Strength lbs/sq.in. 5990

- Yield Temperature 158

- Weight lbs/cu.in 0.339

- Brinnell Hardness No. (500 kg) 9.2

- Growth/Shrinkage - Time after Casting: after 2 mi.: 0.0025

- after 1 hour: 0.0051

- after 24 hrs: 0.0051

- after 500 hrs: 0.0057

-

This is a Bismuth based Eutectic low melting alloy used for tooling and production aids. It provides you with easily castable material that is ready for use as soon as it freezes. This alloy can be recovered easily and recycled into new uses a number of times. It is mainly used in the optical industry for lens blocking when grinding glass, plastic lenses and optical components. It's low meeting point allows it not to distort the glass or plastic which it supports, Also can be used for proof casting as well. In comparison to its 117 Deg F. counterpart this alloy does not contain Cadmium. Forms: - 2 Lb. Cake Even Weight

- 1/8" Dia Solid Wire

- Capping Bars

Belmont Product Code 2491 Nominal Composition: - 49% Bi

- 18% Pb

- 21% In

- 12% Sn

Technical Info: - Melting Point - Solidus 136 F, 58 C

- Melting Point - Liquidus 136 F, 58 C

- Short-Term Tensile Strength lbs/sq.in. 6300

- Yield Temperature 136

- Weight lbs/cu.in 0.31

- Brinnell Hardness No. (500 kg) 14

- Growth/Shrinkage - Time after Casting: after 2 mi.: 0.0003

- after 1 hour: 0

- after 24 hrs: -0.0002

- after 500 hrs: -0.0002

-

This is a Bismuth based Eutectic low melting alloy used very often to bend tubes and rolled or extruded shapes. This alloy which is normally used for tubes greater than 2-1/2" Diameter allows them to be bent or formed to the desired shape without any kinks. With out using this material the tubes or shapes may kink or bend irregularly. It can also be used for work-holding, fusible safety devices and low temperature soldering. Forms: - Cakes

- 1/4# Capping Bar

- 1/8" Dia Solid Wire

- 10-20 Mesh

- 1-1/2 Lb. Regular Bars

- 40 Lb. Pigs

Belmont Product Code 2562 Nominal Composition: - 55.5% Bi

- 44.5% Pb

Technical Info: - Melting Point - Solidus 255 F, 124 C

- Melting Point - Liquidus 255 F, 124 C

- Short-Term Tensile Strength lbs/sq.in. 6400

- Yield Temperature 255

- Weight lbs/cu.in 0.38

- Brinnell Hardness No. (500 kg) 10.2

- Growth/Shrinkage - Time after Casting: after 2 mi.: -0.0008

- after 1 hour: -0.0008

- after 24 hrs: 0.0008

- after 500 hrs: 0.0022

-

This is a Bismuth based non-eutectic alloy commonly used as a low-melting solder and also to make custom shaped blocks. It is also used to make metal inlays in wood and also useful for repairing antiques as the low melting temperature of Wood's metal makes it unlikely this will harm the original piece. Forms: - Capping Bars

- Cakes

- 1/4" Dia. Solid Wire

- 1/8" Dia Solid Wire

Belmont Product Code 2502 Nominal Composition: - 50% Bi

- 25% Pb

- 12.5% Sn

- 12.5% Cd

Technical Info: - Melting Point - Solidus 158 F, 70 C

- Melting Point - Liquidus 169 F, 76 C

- Short-Term Tensile Strength lbs/sq.in. 6100

- Yield Temperature 158

- Weight lbs/cu.in 0.347

- Brinnell Hardness No. (500 kg) 9.3

- Growth/Shrinkage - Time after Casting: after 2 mi.: -0.0001

- after 1 hour: 0.0002

- after 24 hrs: 0.0031

- after 500 hrs: 0.0035

-

This material is used for soldering applications primarily in electronic circuit boards and various high voltage or high power applications. Consisting of 60% Bismuth and 40% Cadmium the shape of the bars are approx. 1/4' x 1/4" x 14" long. Forms: - 1/4" Capping Bar

Belmont Product Code 2601 Nominal Composition: - 60% Bi

- 40% Cd

-

Silicon brass a copper/zinc alloy with some tin and / or lead tossed in to improve hardness, color and machining qualities. This alloy is especially desirable for fluid moving applications. Forms: - 1/2" Polished Cubes

- 1/2" x 14 Mesh Polished Shot

- 2" Cut Polished Pcs.

- 2-20 Ingot

- 2-5 Ingot

- Slabs

Belmont Product Code 4811 Nominal Composition: - 82.5% Cu

- 4% Si

- 13.5% Zn

Technical Info: - CDA #: 87500

-

95/5 Zinc Aluminum M Solder alloy composed of 95% Zinc 5% Aluminum that exhibits remarkable coating corrosion resistance and adhesion. Resistance to corrosion of joints soldered with 95ZN-5AL is superior to that obtainable with other solders; it is comparable to that obtain with pure Zinc. Forms: - 1/4# Capping Bar

- 4-20 Ingot

- Approx. 1 Lb. Regular Bars

Belmont Product Code 8951 Nominal Composition: - 95% Zn

- 5% Al

-

-

Zamak 5 should be consider when moderately greater hardness strength and creep resistance is require over Zamak 3. Zamak 5 has the same composition as Zamak 3 with the additional of 1% copper in order to increase strength (by approximately 10%), hardness and corrosive resistance, but reduces ductility. Zamak 5, or Zinc alloy 5, is the most widely used Zinc die casting in Europe. It has higher strengh and less ductility than other members of the Zamak. Forms: - 1/4# Capping Bar

- 4-20 Ingot

- Approx. 1 Lb. Regular Bars

- Margash Bar

Belmont Product Code 89511 Nominal Composition: - 95% Zn

- 4% Al

- 1% Cu