Showing all 9 results

Featured products

-

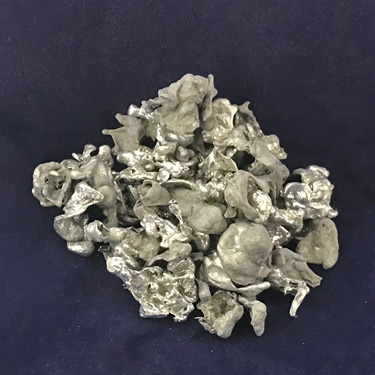

Can be considered either a deoxidizer or grain refiner. Generally, for pure copper its role would be deoxidizing but in brasses it’s more of a grain refiner. Forms: - 3/4" & Down Polished Shot

- 3/4" & Down Unpolished Shot

- 40-15 Waffle

- 4-5 Oz Pcs.

Belmont Product Code 4987 Nominal Composition: - 98% Cu

- 2% B

-

-

Phos Copper is the most commonly used deoxidizer. Effectively removes oxygen from molten metal with little or no reaction or dross formation. Forms: - 3 Mesh Shot

- Approx. 15 Lb. Waffle Ingots

Belmont Product Code 48514 Nominal Composition: - 85% Cu

- 15% P

-

Silicon ranks second to Copper in the importance in Aluminum Casting Alloys. Silicon reduces the melting temperature without causing brittleness, increases fluidity, and reduces hot tearing. This improves overall casting characteristics allowing for thinner and more intricate castings to be made. Silicon additions can reduce the amount casting shrinkage and in general Aluminum-Silicon Alloys have been resistance to corrosion. Forms: - 16-17 Waffle

- 30-60 Mesh Granular

Belmont Product Code 1503 Nominal Composition: - 50% Al

- 50% Si

-

-

The presence of Iron in Aluminum aides in the decrease of hot tears, improves tensile, yield, and hardness and preserves strength at elevated temperature. Forms: - 16-20 Waffle

Belmont Product Code 19013 Nominal Composition: - 90% Al

- 10% Fe

-

Phosphorus is used in tin as in tin solders to suppress dross formation keeping the metal bath cleaner. Forms: - Waffle

Belmont Product Code 7955 Nominal Composition: - 95% Sn

- 5% P

-