Showing all 5 results

Featured products

-

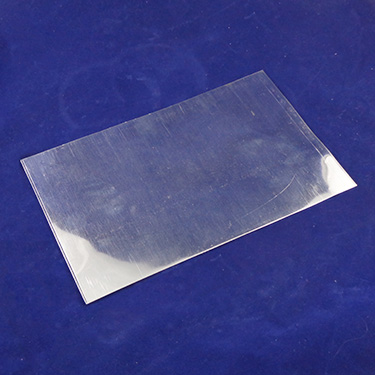

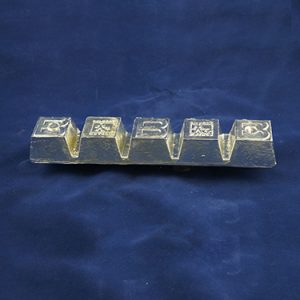

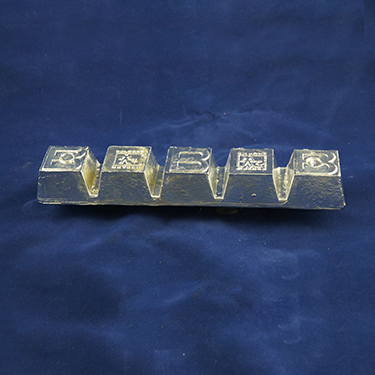

Our standard Grade A Tin is sourced from highest quality supplier and is certified conflict free. We offer this material in a wide variety of forms so we can tailor the metal for your needs. Forms: - Granular

- Pigs

- Approx. 1 Lb. Regular Bars

- Sheet

- Cast Flat Anodes

- 1/4# Capping Bar

- Wire

- 2-5 Ingot

- 8-20 Mesh Shot

- Slabs

Belmont Product Code 7001 Nominal Composition: - 99.85 Sn

- Bal

-

We offer Ultra Pure Tin that is used for specific applications where higher grades are required. Our grade is refined to the highest standards. Ultra Pure Tin has extremely low levels of lead, cadmium, antimony, and copper. And we offer this material in a variety of forms that we can tailor to your application. Forms: - 8-20 Mesh Shot

- Approx. 1 Lb. Bars

- Approx. 53 Lb. Pigs

- Approx. 5 Lb. Ingots

Belmont Product Code 7004 Nominal Composition: - 99.99% Sn

- Bal

-

For high speed and heavy load applications slightly softer than Grade 1. Forms: - 5-6 Ingot

- 1/8", 1/16", 1/32", 3/16", 5/32" Dia Solid Wire

- Pigs

Belmont Product Code 7881 Nominal Composition: - 89% Sn

- 7.5% Sb

- 3.5% Cu

Technical Info: - ASTM B-23 Grade # : 2

- Melting Point-Solidus : 241 C, 466 F

- Melting Point - Liquidus : 354 C, 669 F

- Pouring Temperature : 425 C, 795 F

-

-

This is a Bismuth based Eutectic low melting alloy whose main attribute is the minimal volume change between its liquid and solid state. This is the highest melting point of the bismuth-base alloys commonly used in the industry and provides an easily castable material ready for use soon after it freezes. It is used primarily for holding parts such as jet engine blades for machining and also for foundry patterns and fusible elements in safety devices. Forms: - Cakes

- .063" Dia. Solid Wire on 1 Lb. Spools

- 1/8" x 18" Cast Strips

- 1/8" X Down Shot

- 30 Lb. Pigs

- 5 lb. Ingot

Belmont Product Code 2581 Nominal Composition: - 58% Bi

- 42% Sn

Technical Info: - Melting Point - Solidus 281 F, 138 C

- Melting Point - Liquidus 281 F, 138 C

- Short-Term Tensile Strength lbs/sq.in. 8000

- Yield Temperature 281

- Weight lbs/cu.in 0.315

- Brinnell Hardness No. (500 kg) 22

- Growth/Shrinkage - Time after Casting: after 2 mi.: 0.0007

- after 1 hour: 0.0006

- after 24 hrs: 0.0005

- after 500 hrs: 0.0005