Zinc in used in many applications from die casting to electroplating. However, zinc, by itself, is brittle and weak. For that reason, it’s often alloyed with other metals, including titanium. When zinc is alloyed with titanium, it becomes lightweight and exceptionally strong. Here at Belmont Metals, we offer zinc titanium alloys for manufacturing processes.

Properties of Zinc

Zinc is used in many different applications. For example, you’ve probably heard of galvanized steel. Galvanized steel, which is steel that has been coated with layers of zinc in order to reduce the chances of corrosion. By itself or in pure forms, however, zinc tends to be a weak and brittle metal, especially when compared to steel.

- Blueish-white metal with a density of 7.13 g/cm3

- Forms a dull gray oxide coating when exposed to air

- Becomes malleable at 212F, Melts at 788F and boils at 1662.8

- Turns into a powder above 392F

- Known as a good conductor

Properties of Titanium

Titanium is known for its strength and durability. It’s often used for surgical instruments and airplane components, but it has uses in almost every industry. Titanium is nearly twice as strong as steel and 45 percent lighter.

- Dark gray to silver appearance

- Achieves tensile strengths of between 20,000 to 200,000psi

- Melts at 3034F

- Not a good conductor

- Not magnetic

- Can be alloyed with most other metals

Benefits and Uses of Zinc Titanium Alloys

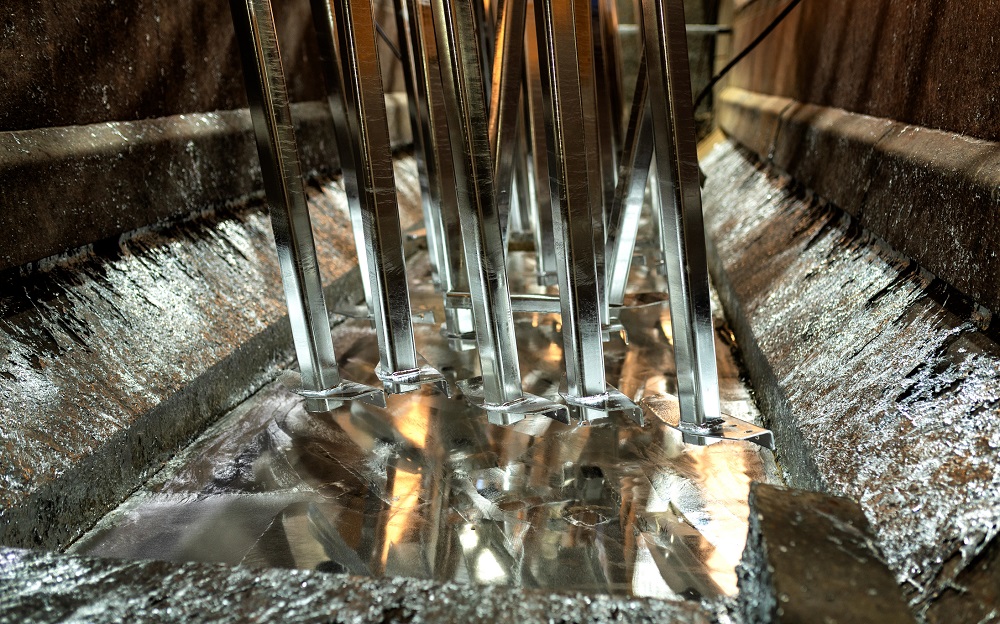

Zinc titanium alloys re primarily used for die casting and in different types of wrought applications. When it comes to die casting, zinc titanium alloys can be used with all types of molds, including permanent, shell, sand and plaster molds as well as for investment casting. It’s preferred by manufacturers because the alloy has a lower melting point, offers reduced wear and tear on machinery and a faster production timeline. Wrought zinc alloys achieve excellent corrosion resistance and are often used to manufacture photoengraver’s plates and for use in dry cell batteries as well as for stamping and coining.

Zinc titanium alloys are also often used in forging and extrusion applications, and finished products can be electroplated or painted. If end products require two or more sections or pieces, those sections can be joined via welding, soldering or adhesive joining.

Sourcing Zinc Titanium Alloys from Belmont Metals

Here at Belmont Metals, we have many different types of zinc alloys, including zinc titanium alloys that are great for a variety of industries, including manufacturing and industrial applications as well as for research purposes. If you need a specific zinc titanium alloy, we do provide custom alloys for research and development purposes, and we can supply custom alloys in the five to 10-pound range for specific applications and testing.

To learn more about our zinc titanium alloys and master alloys or to make a purchase, give us a call at 718-342-4900 or visit our easy to use online store.