Cobalt has seen rapid market growth for the past few decades. It has wide ranging uses in a number of applications as prices have skyrocketed for this metal since 2017. With the increase in demand, and its use in certain specific applications, manufacturers have to consider whether they will have enough supplies for their current and future production needs.

Cobalt Properties

Cobalt is a silver-white metal that has a slight bluish tinge. In its pure state, it is brittle and hard. The metal also has magnetic properties, as it is considered a ferromagnetic like iron. Since it is brittle in its pure form, it is used as an additive and alloy in other materials to improve their characteristics and physical properties. Cobalt has a very high melting point as it maintains its magnetic properties even at higher temperatures. It is also hard-wearing at these temperatures, which makes it suitable when added to other metals such as high speed steel, aluminum, and nickel.

Cobalt Applications and Availability

Cobalt is used in numerous, diverse industries. It can be found in automotive, aerospace, industrial, chemical and military applications. Some common products that contain cobalt include:

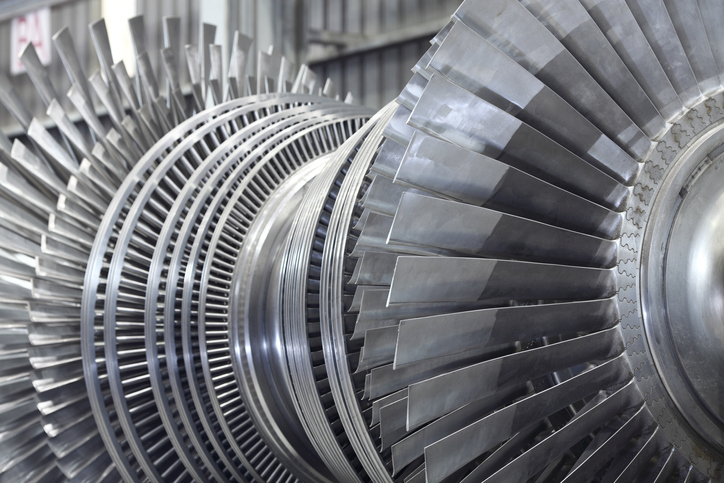

- gas turbine engines

- automobile airbags

- cemented carbides

- wear-resistant and corrosion resistant alloys

- magnetic recording media

- petroleum and chemical catalysts

- vehicle batteries

Cobalt can also be used for electroplating for many products, drying agents in paints, and as dyes and pigments. The main leading uses of this metal are for rechargeable battery electrodes and jet turbine blades.

While cobalt is not a rare metal, about 55% of its global supply is mined from the Democratic Republic of the Congo (DRC). It is also mined in China, Zambia, Australia and Russia. Many of the cobalt materials are formed from by-products when refining nickel.

The availability of cobalt has been in flux for many years. Rising demands for this metal in the electric vehicle and aerospace industries have leveled off due to the recent pandemic. As more surplus is created from manufacturers pulling orders for these products, prices that were previously skyrocketing since 2017 are expected to lower through 2020. So cobalt supplies will continue to meet present short-term demand.

For future availability, cobalt demand will still remain at a level pace due to the continuing trade wars with China and the pandemic shutdown for several countries. However, demand for used in the production of batteries, electric vehicles and other electronic products is expected to rebound and recover at a faster pace than in other industries, such as aerospace, in the near future. With incentives for cleaner air initiatives offered by differing government agencies around the world, manufacturers will have to consider and revamp their supply chain strategies to adjust to these customer demand fluctuations, availability and prices that may impact their production processes when using this metal.

Here at Belmont Metals, we offer 99.9% cobalt as squares and down broken cathodes to manufacturers. Contact us today to learn more.