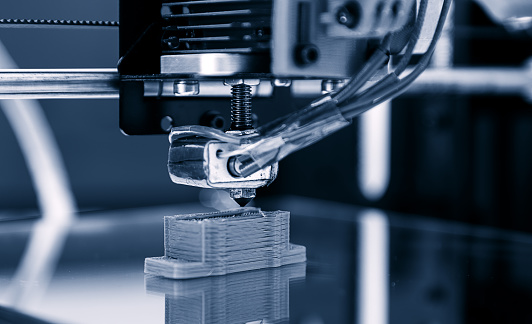

Production manufacturers use the term additive manufacturing to refer to 3D printing on an industrial scale. Many high-value products rely on aluminum alloys. In addition, production-scale 3D printing keeps growing increasingly popular. Thus, effective aluminum alloys for additive manufacturing have received much attention from manufacturers, researchers, and various industries.

Manufacturers often turn to additive manufacturing because the process reduces waste, lowering the quantity of materials needed for production. In addition, 3D printing decreases the lead time for developing prototypes, so it can help decrease the amount of time required to create products for production.

Pros and Cons of Common Aluminum Alloys Used for 3D printing

Previously, companies often reserved 3D printing for prototyping or rarely-ordered products. Nowadays, additive manufacturing can offer a cost-effective solution for designers and manufacturers. In particular, automotive, aerospace, and other industries benefit from lightweight and chemical-resistant aluminum alloys.

For instance, Ford recently announced their intention to use additive manufacturing to produce 200,000 vehicle parts on an industrial scale. The company had to develop a specialized alloy but found the overall process cheaper and faster than alternatives. Also, 3D printing allowed Ford to make the part lighter in weight than its previous production method.

Mobility Engineering contrasted aluminum alloys to copper, titanium, and magnesium alloys for additive manufacturing. They found that aluminum may not offer the best choice for some properties. However, it often provides the optimal combination of ease of manufacture, performance, and cost. Many specialized aluminum alloys for 3D printing also contain silicone for flowability and magnesium for strength.

Popular Aluminum Alloys for Additive Manufacturing

Manufacturers can choose between several aluminum alloys for 3D printing based on their application’s requirements and the machines they plan to use. Some specific examples of common choices include:

- AISi10Mg: The strength and hardness of this alloy make it a common choice for such applications as ductwork, tools, and engine parts.

- AISi10Mg: The lighter weight and durability of this combination of aluminum, magnesium, and silicone make it ideal for complex geometries and fine lines.

- F357: This alloy can produce lightweight, strong products and is often used in the automotive, defense, and aerospace industries.

In addition, 6000-series aluminum alloys may offer desirable properties, such as high conductivity, elasticity, and corrosion resistance. In contrast, the 7000-series can offer the strength needed for high-stress applications, like airplane parts.

In addition to aluminum, other common metals used in additive manufacturing include copper, titanium, stainless steel, chrome, and even silver, gold, and bronze. Most commonly, 3D printing uses powdered aluminum alloys but might also employ other forms, like wire, rods, and filaments.

Belmont Metals can assist in the development of specialized alloys for additive manufacturing, Shop online for additive manufacturing alloys or contact Belmont Metals with queries.