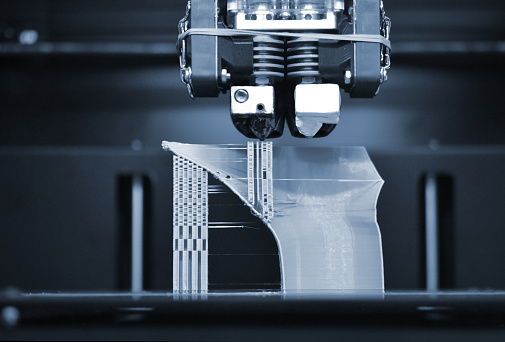

Additive manufacturing processes involve using materials to create parts, components, and finished products by layering the materials together. These processes create both simple and complex geometric parts for a range of industries including medical, aerospace, and automotive. In addition, many manufacturers use additive manufacturing for prototyping design concepts. These prototypes are made quickly and modified until the chosen design is selected. Then the manufacturer may mass produce the items once gaining approval and authorization from the customer.

A customer has a wide selection of material to use for their products when selecting additive manufacturing techniques. Metals are often used in various forms, including wire and in powdered form, to create simple and complex 3-D objects. Due to advancing technologies, other metal forms have been used such as rods and filaments.

Metals Used in Additive Manufacturing

The types of metals are wide-ranging. Common metals include the following stainless steel, aluminum, titanium, cobalt chrome, and Inconel. Gold, silver, bronze, and nickel are also metals that may be used in this process.

Many metals are chosen due to their corrosion resistance, ductility, and strength. However, pricing can become expensive when using certain metals in this process, such as titanium and stainless steel. In the case of stainless steel, some metals also take too much time to create an item using additive manufacturing.

Metals used in manufacturing are often non-reflective. Non-reflective metals do not reflect light away or back to its source. Since some additive manufacturing processes use lasers or ultraviolet light to heat, melt, or cure materials together, a reflective metal would send the laser or UV light back to its source. So the metal materials would not bond to each other and could damage equipment.

Newer innovations have switched to using a blue light laser that does not reflect the laser or light away. This process allows reflective metals such as copper to be used in additive manufacturing processes. Some techniques are more suitable for certain metals, so speaking with the manufacturer during the design stages may allow you to figure out the best options.

Benefits of Additive Manufacturing

There are several benefits to using the additive manufacturing process. A main advantage of this process involves the efficient use of materials to lessen waste. Instead of removing materials that will later be thrown away, additive manufacturing produces a lower amount of waste since materials are layered on top of each other. So manufacturers can decrease procurement costs when acquiring raw materials for their processes. They also decrease lead times as well as have the ability to perform rapid prototyping.

Also, in addition to using metals for additive manufacturing, ceramics, thermoplastics, and biochemicals may also be used. This process may create parts with complex internal structures as a whole single item instead of creating multiple pieces that will later need to be assembled together.