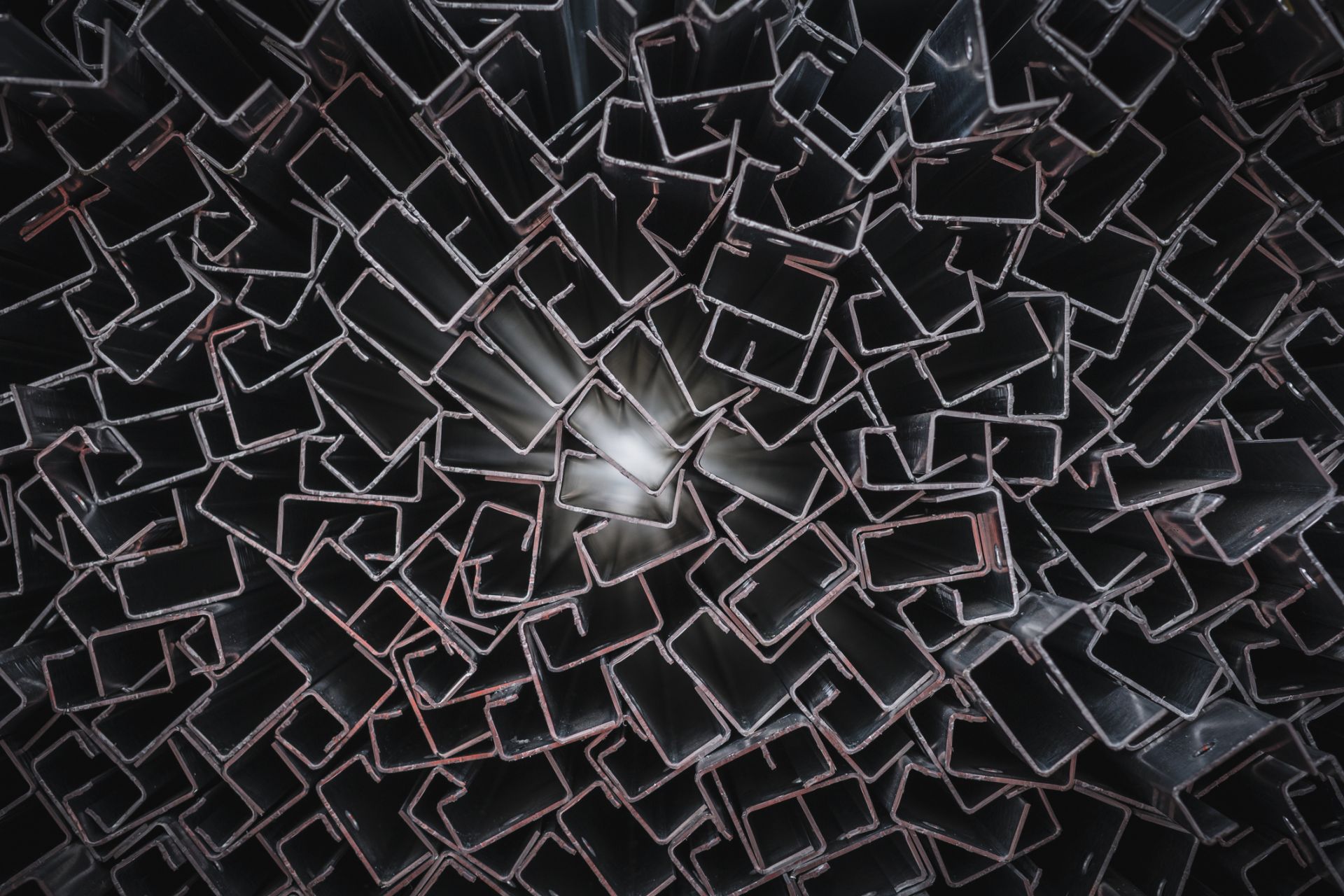

Satisfying Quality Assurance While Meeting Client Specifications

Manufacturers of delicate components look beyond just creating a product that will meet customer demand. They must also focus on quality parts that must stand up to the test of time. Using custom alloys can allow some companies to overcome manufacturing challenges when standard alloys are prone to failure when crafted into specific components. Quality…