Showing all 11 results

Featured products

-

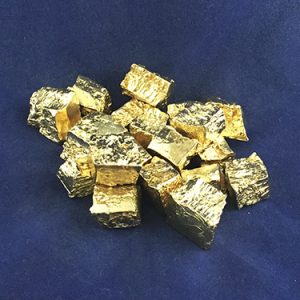

Bell metal is a hard alloy used for making bells and related instruments, such as cymbals. It is a form of bronze with a higher tin content, usually in approximately a 4:1 ratio of copper to tin (typically, 78% copper, 22% tin by mass). We offer this material in Ingot, shot, and cut pieces. Forms: - Ingot

- Irregular Shot

- 1/2" Polished Cubes

- 2" Cut Pieces

Belmont Product Code 4788 Nominal Composition: - Cu: 78%

- Sn: 22%

-

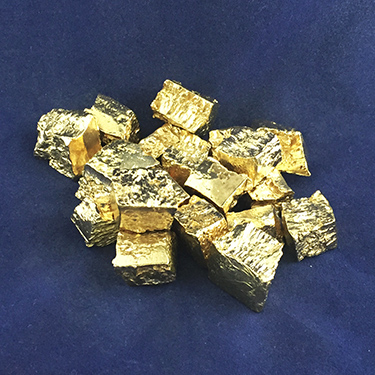

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - 1" x 1" x 1" Nuggets

- Cast Flat Top Anode Approx 1-1/4" Each

Belmont Product Code 47018A Nominal Composition: - 30% Zn

- 70% Cu

Technical Info: - CDA #: 96400

-

Brass, which is an alloy made of copper and zinc, can be varied to create a wide range of brasses with varying properties, is widely used for decorative applications in antiques and ox finishes. Brass plating is also a great alternation for sealing zinc die-castings for post molding operations. Brass plating provides an excellent diffusion barrier preventing components of the base material from migrating into the subsequent plating layers. Forms: - Cast Flat Top Anode Approx 1-1/4" Each

- 1" x 1" x 1" Nuggets

Belmont Product Code 48012A Nominal Composition: - 20% Zn

- 80% Cu

Technical Info: - CDA #: 87300

-

Leaded red brass is typically found in plumbing applications. It is known for its reasonable cost with good machining and casting properties. The lead content ensures pressure tightness. Red brass is also used for low-cost bearing materials under low loads. Forms: - 1" x 6" x 12" Slabs

- 2-20 Ingot

- 2" Sheared Pcs.

Belmont Product Code 4852 Nominal Composition: - 85% Cu

- 5% Zn

- 5% Sn

- 5% Pb

Technical Info: - CDA #: 83600

-

Navy M Leaded Bronze C92200 Bronze is an alloy of copper, further classified as a bronze (copper-tin- alloy). Is used for a variety of steam pressure applications involving temperatures up to 550 F. Forms: - 1-20 Ingot

Belmont Product Code 4884 Nominal Composition: - 88% Cu

- 4% Zn

- 8% Sn

Technical Info: - CDA #: 90300