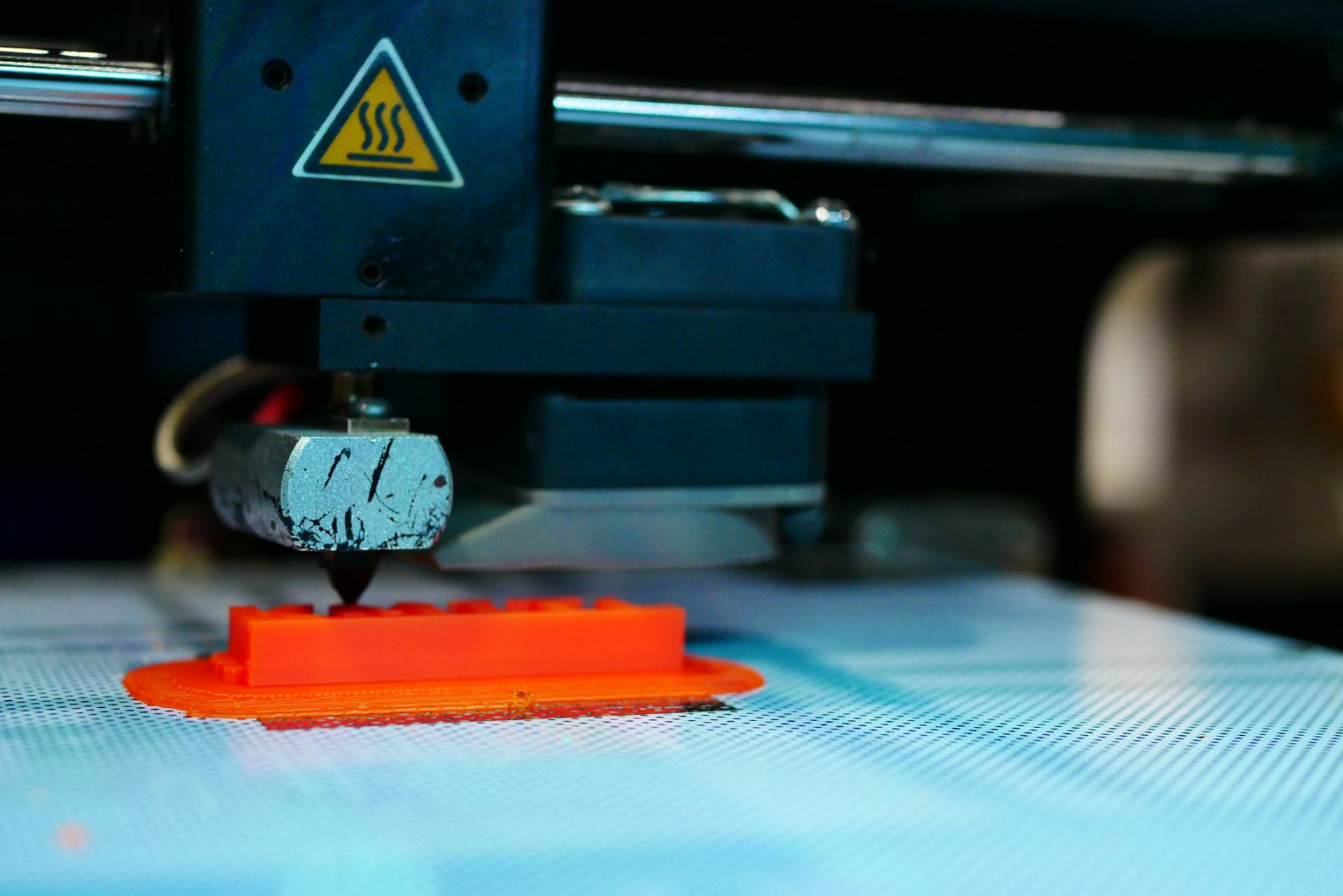

The technologies of 3D printing have advanced in many different ways as new materials are being used in the production of parts and finished products. Often, we think of thermoplastic materials in 3D printing components. There are even 3D printers that use food materials. Yet powdered metals such as nickel alloys and copper can be used in 3D metal printing applications.

Creating Components Through Printing Processes

Manufacturers looking to create mass produced components and parts are looking at 3D printing capabilities to design prototypes that can be tested and changed before the production run for the final product begins. When creating prototypes using traditional methods and metals, a lot of material waste can be created just to make a prototype that will be changed numerous times to increase its functionality. With 3D printing using powdered metals, less materials are wasted as the majority of the powdered metal goes into the prototype itself.

In addition to using powdered metal for 3D printing applications where a prototype will be created or a finished product, the powdered metal can also be used to fill out products where more thickness is desired. The 3D printer can provide greater control for these topologically optimized parts. Powdered metals commonly used in 3D printing include:

- Copper/Brass/Bronze: These powdered metals are often found in jewelry and art crafts. Filaments filled with powdered copper, bronze and brass are then extruded to make the 3D component.

- Titanium: Titanium is commonly used in 3D printing processes due to its strength and lightness as 3D printed components can be found in the aerospace, automotive, medical and tooling industries. Creating powdered titanium 3D components can be dangerous as it is highly reactive and can explode if not done in argon gas atmosphere or vacuum environment.

- Steel: Stainless steel is also commonly used in 3D printing because it is strong and has a high elastic property. It is commonly used in industrial components and jewelry as is applied using a filament method.

- Aluminum: Aluminum’s popularity in 3D printing processes has increased throughout the years. Due to its versatility and lightness, this aluminum-based alloys can be found in functional parts that have a low weight and high strength characteristics.

- Gold/Silver/Platinum: Precious metals are commonly printed using the 3D method to create medical products, electronics, and jewelry. The laser sintering method is a common application method.

Ways that Powdered Metal Are Used in 3D Printing

There are typically 3 technological methods on how powdered metal is used in 3D printing: direct metal laser sintering, metal binder jetting and directed energy deposition.

Direct Metal Laser Sintering: This method involves placing a bed of the powdered metal onto the surface. Then a laser melts the powdered metal into a 2-dimensional design. Another layer of powdered metal is added and the laser process is repeated until a 3D shape begins to form from the combined 2D melted layers.

Metal Binder Jetting: In metal binder jetting, the powdered metal is combined with a liquid resin. The 3D printer will lay down a layer of powdered metal and then the binding resin layer until the component is completely formed.

Directed Energy Deposition: This method consists of an extruder and a laser. The powdered metal is placed into the extruder. As a stream of the powdered metal comes out, it is met by the laser on the top of the component. While this method can be used to create parts, it can also be used to repair broken components.

Belmont Metals based in Brooklyn New York has been providing manufacturers and jewelers cost-effective metal products used in a variety of applications. Powdered metals are a popular choice, especially for 3D printing capabilities, to help control material costs while providing high quality products. Contact our team today to learn more.