With evidence of widespread use dating back to ancient Rome, lead has been a popular metal for millennia. However, despite being flexible and useful for diverse applications, it has fallen out of favor in recent decades. Notably, growing concerns around lead’s significant health and environmental safety risks have driven companies to search for alternatives. In that search, bismuth has emerged as the top contender.

Bismuth Versus Lead

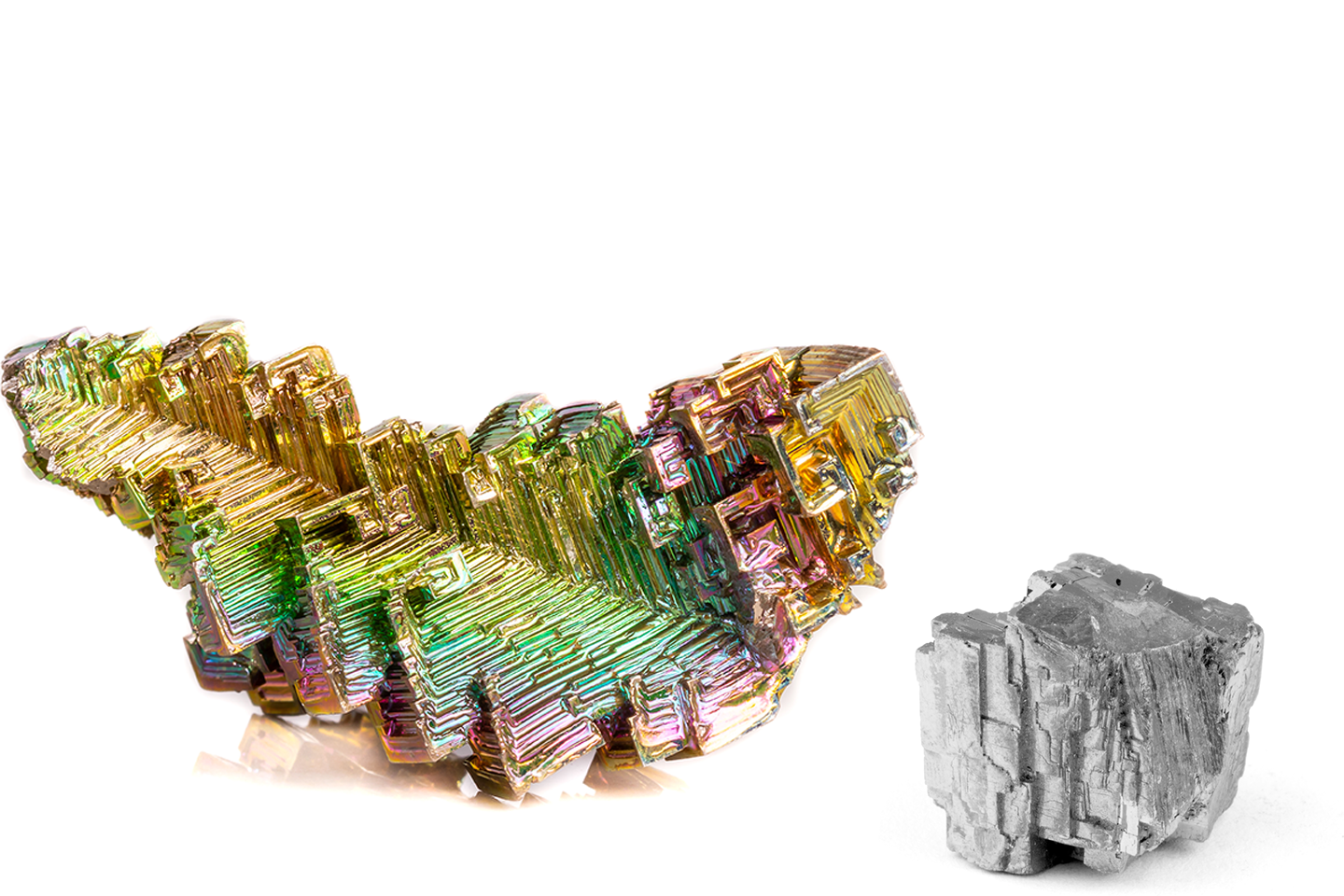

Lead is dense (11.34 g/cm³) and malleable with a melting point of 621.4 degrees Fahrenheit (327.5 degrees Celsius). These properties make it easy to manipulate and mold. Historically, lead was the material of choice for applications, including ballast, pipes, casting, and soldering.

Bismuth has a similar density (9.78 g/cm³) and a lower melting point of 520.5 degrees Fahrenheit (271.5 degrees Celsius). It’s suitable for weight-critical applications, fusible alloys, and products that require minimal thermal transfer. More importantly, bismuth is nontoxic, biologically inert, and safer for consumers.

Companies choosing between lead and bismuth typically consider three factors:

- Toxicity: The World Health Organization classifies lead as a toxic substance — there’s no safe level of exposure. It poses profound health risks, including kidney damage, cardiovascular problems, and stillbirth. Nontoxic bismuth is a safer alternative for consumer-facing applications.

- Cost considerations: Lead is affordable and easy to access, thanks to an abundant supply and established mining and refining processes. Bismuth is more expensive and requires higher initial cash outlays. The purchase price is just one consideration; since bismuth requires fewer health and environmental protections, it creates long-term savings.

- Environmental impact: Lead has documented environmental hazards; it can contaminate water, reduce biodiversity, and damage animals’ reproductive and neurological systems. Low-toxicity bismuth is a green alternative. Used as a lead replacement, it can reduce the environmental impact of heavy metals.

The Shift From Lead to Bismuth

The risks of lead have prompted a shift toward alternative metals. To avoid the practical and regulatory dangers of lead poisoning and environmental pollution, businesses are switching from lead to bismuth.

Bismuth is particularly attractive to additive manufacturers. Its properties provide important advantages for printing alloys:

- Melting point and printer compatibility: Lead’s higher melting point requires a printer that can maintain adequate temperatures. Since bismuth has a lower melting point, it’s suitable for lower-temperature equipment.

- Print speed and precision: Lead solidifies quickly and tends to warp, making it difficult to maintain print precision, detail, and integrity. Bismuth has a stable and predictable cooling behavior that enhances precision and quality.

- Material interaction and printer wear: Lead is malleable but abrasive and may increase wear on high-contact printer components. Bismuth alloys offer a more printer-friendly solution. Pure bismuth is brittle and should be kept in a dry, closed container.

- Health and environmental considerations: Lead can create toxic vapor or dust, which necessitates extensive safety protocols. Bismuth is a lower-risk option for high traffic environments; it’s also easier to dispose of or recycle.

- Alloy behavior and stability. The inherent softness of lead can limit print strength and stability. Bismuth alloys are stable, so they enhance dimensional accuracy and structural integrity.

Make the Switch to Bismuth

Lead has been used for centuries, but modern concerns around public health and environmental safety mean that companies must opt for safer alternatives. With its similar properties and nontoxic nature, bismuth is a key contender as a preferred substitute.

Belmont Metals provides a variety of bismuth ready for your next project. Reach out to our team for more information.