While lead is toxic to people and as the metal is avoided in food-based applications or when equipment comes in human contact, it is still in wide use today. This metal has excellent corrosion resistance and ductility, as it may be used for applications such as lining storage tanks containing acidic substances, in the manufacturing of lead-acid storage batteries, radiation shielding, and lead sheathes for cables. Lead also may be allowed to other metals to provide different mechanical and structural properties.

If looking for a metal to alloy with lead, antimony is one of the most common metals. Antimony is a very stable metal that does not conduct heat or electricity. When in a pure form, the metal is used in the manufacturing of semiconductor devices. Antimony that is alloyed to other metals may be used in cable sheathing, flame-proofing materials, and infrared detectors. Antimony is commonly added to lead to provide a range of benefits.

Antimonial Lead

Antimonial lead alloys consist of around 1% up to 10%+ of antimony added into the lead base metal. The antimony is used as a lead hardener. While lead’s ductility is desired for machining the metal, pure lead is very soft. With the addition of antimony, the lead becomes very hard and durable. At the same token, the antimony allows the lead to flow better when performing castings as the molten lead can fill every part of the mold without leaving voids.

Antimony also increases the corrosion resistance of the lead due to its stability and resistance to oxidation. The antimonial lead becomes resistant to most environments it is used in. It does not negatively impact many of the lead’s good qualities. However, please take note that antimony does make lead more brittle. So extra care must be taken during casting and machining techniques.

Applications of Antimonial Lead

Due to the small amounts of antimony added into the lead, antimonial lead can still be used for any of the same applications as lead. It is cast into ammunition bullets as well as made into storage tank linings, radiation shielding, and storage-battery plates

Antimonial lead may also be used to created ballasts, wheel weights, sheet lead, and bearings. When joining metal surfaces together, antimonial lead may be used for step soldering where different melting points are used. Step soldering is a common method for making printed circuit board (PCB) assemblies.

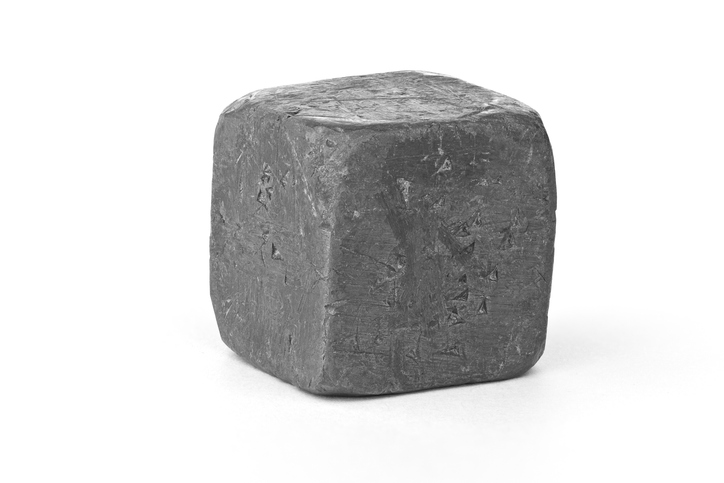

Antimonial lead may come in many forms for manufacturing processes, such as cube, ingot, rods, and sheets. Reach out to Belmont Metals if you are in need of antimonial lead for your applications. Our technicians can discuss the types of alloys and base metals for your project to come of the chemistries that will work well with the application.