At Belmont Metals, we’re dedicated to delivering cutting-edge metals and alloys that empower metal buyers and engineers like you to innovate. Today, we’re thrilled to spotlight Scalmalloy, a groundbreaking aluminum-magnesium-scandium alloy that’s revolutionizing additive manufacturing. With its superior Scalmalloy properties, this high-performance material is ideal for demanding applications across industries. Whether you’re exploring Scalmalloy for aerospace prototypes or automotive components, Belmont Metals is your trusted source. Visit www.belmontmetals.com to discover how Scalmalloy can elevate your projects.

Scalmalloy’s properties make it a standout in the world of additive manufacturing. This alloy boasts exceptional tensile strength exceeding 500 MPa, combining the lightness of aluminum with scandium-enhanced durability. Its unique microstructure, refined through rapid cooling in laser-powder bed fusion (LPBF), delivers remarkable ductility and fatigue resistance, outperforming traditional 7000-series aluminum alloys. Scalmalloy’s low density ensures weight savings of up to 30% compared to conventional materials, while its excellent corrosion resistance—comparable to 5000-series alloys—protects against harsh environments like marine and aerospace settings. Additionally, Scalmalloy maintains stability at temperatures up to 250°C, with low thermal expansion and superior weldability, making it versatile for complex designs.

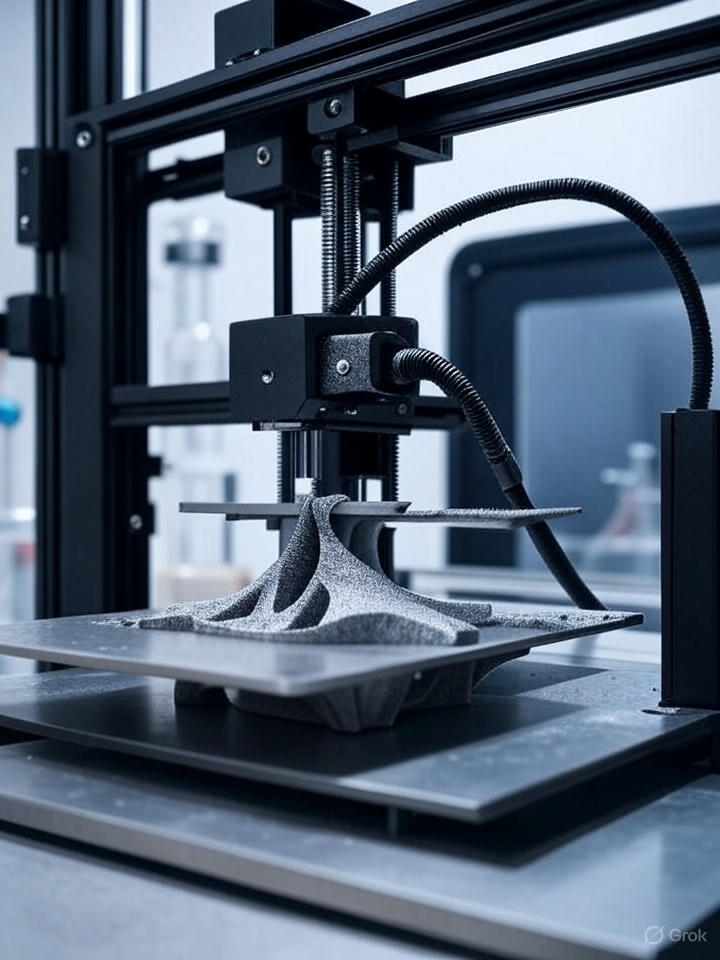

What sets Scalmalloy apart in additive manufacturing applications is its optimization for processes like selective laser melting (SLM) and direct metal laser sintering (DMLS). Invented by APWORKS, Scalmalloy enables the creation of intricate, near-net-shape parts with minimal waste, reducing production time and costs. Its fine grain structure minimizes defects, ensuring high repeatability and precision—crucial for engineers crafting load-bearing components. Recent advancements, including collaborations for North American production, have expanded Scalmalloy’s accessibility, allowing for faster build times and enhanced mechanical performance akin to forged aluminum. Studies from 2025 highlight how natural aging further boosts its microstructure and properties, making Scalmalloy a reliable choice for serial production.

Scalmalloy is widely used in additive manufacturing for aerospace satellite panels, automotive heat exchangers, robotics hydraulic manifolds, and motorsports brackets. In satellites, its lightweight strength supports structural integrity under extreme conditions. For aircraft, Scalmalloy facilitates flight-test components with superior fatigue resistance. Its ability to produce customized, high-strength parts positions Scalmalloy as a game-changer for innovative engineering solutions.

At Belmont Metals, we’re excited to supply premium Scalmalloy tailored to your additive manufacturing needs. This alloy’s properties not only enhance performance but also drive sustainability through efficient material use. Ready to integrate Scalmalloy into your workflow? Head to www.belmontmetals.com for details and expert consultations.