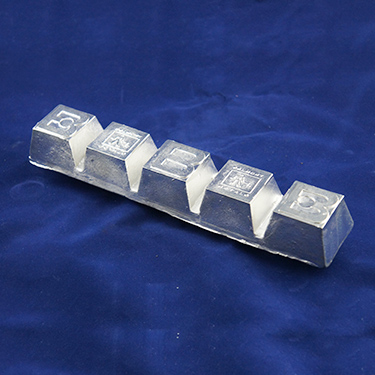

Unlocking Scalmalloy: Properties and Additive Manufacturing Applications at Belmont Metals

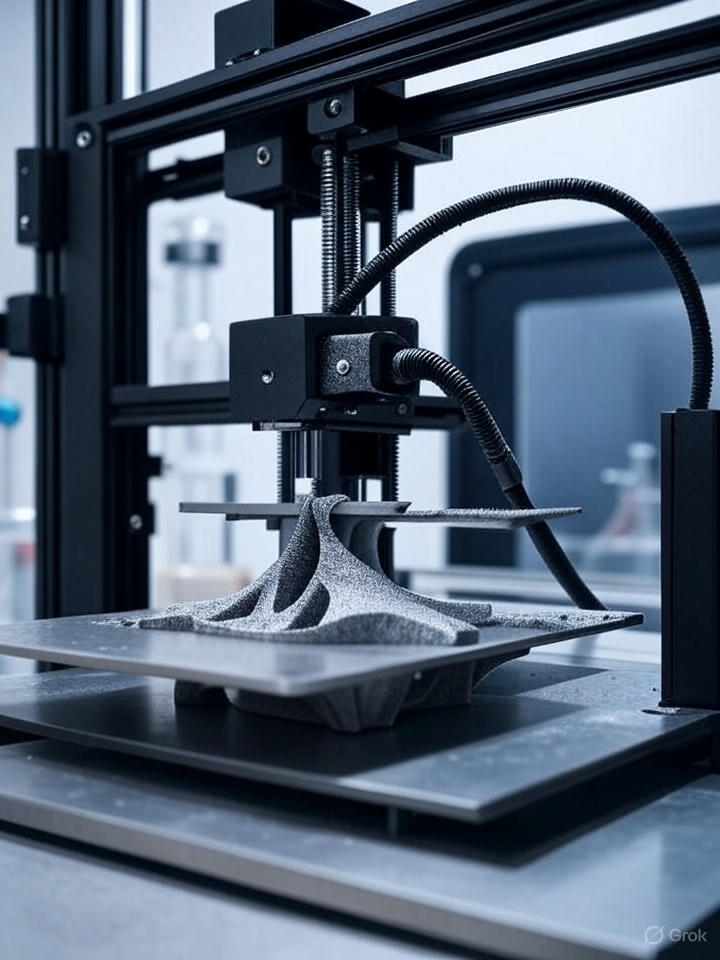

At Belmont Metals, we’re dedicated to delivering cutting-edge metals and alloys that empower metal buyers and engineers like you to innovate. Today, we’re thrilled to spotlight Scalmalloy, a groundbreaking aluminum-magnesium-scandium alloy that’s revolutionizing additive manufacturing. With its superior Scalmalloy properties, this high-performance material is ideal for demanding applications across industries. Whether you’re exploring Scalmalloy for…