Showing all 67 results

-

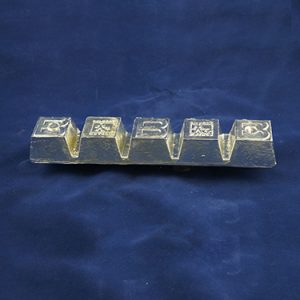

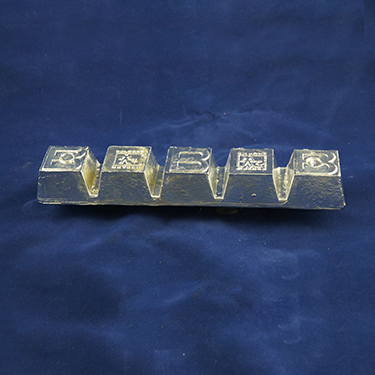

Phosphorus is used in tin as in tin solders to suppress dross formation keeping the metal bath cleaner. Forms: - Waffle

Belmont Product Code 7955 Nominal Composition: - 95% Sn

- 5% P

$316.40

-

$108.70

-

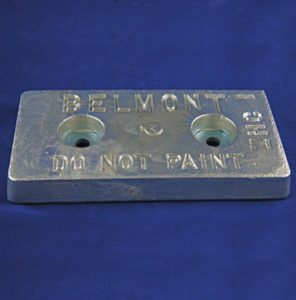

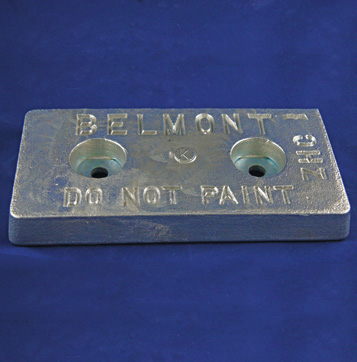

Available for welding or bolt on applications to meet most any requirements for Industrial use or for sale to US Government. Forms: - 1-1/4" x 6" x 12" with Core Strap and 2 Recessed Holes (ZHC-23)

- 2 1/2" x 6" x 12" with Core Strap and 2 Recessed Holes (ZHC-42)

Belmont Product Code 8001ZHC Nominal Composition: - 99.55% Zn

- Bal

$100.30

-

This is a Tin based non-eutectic low melting alloy . The principle uses of this alloy are in applications similar to investment casting in which it substitutes for the so called " lost wax " pattern dies. It's other applications also include proof casting and sealing or soldering in low-temperature applications. Forms: - Cakes

- Slug

Belmont Product Code 2405 Nominal Composition: - 40% Bi

- 60% Sn

Technical Info: - Melting Point - Solidus 281 F, 138 C

- Melting Point - Liquidus 338 F, 170 C

- Short-Term Tensile Strength lbs/sq.in. 8000

- Yield Temperature 302

- Weight lbs/cu.in 0.296

- Brinnell Hardness No. (500 kg) 22

- Growth/Shrinkage - Time after Casting: after 2 mi.: -0.0001

- after 1 hour: -0.0001

- after 24 hrs: -0.0001

- after 500 hrs: -0.0001

$74.00

-

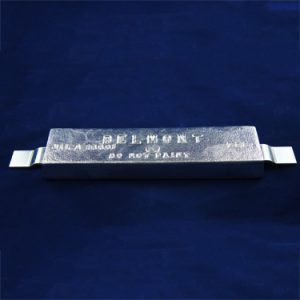

Available for welding or bolt on applications to meet most any requirements for Industrial use or for sale to US Government. Forms: - 1-1/4" x 3" x 12" with 1 Steel Strap approx. 11.5 lbs

- 2 1/2" x 3 1/2" x 12" with 1 Steel Strap approx. 24 lbs

Belmont Product Code 8001ZSS Nominal Composition: - 99.55% Zn

- Bal

$57.40

-

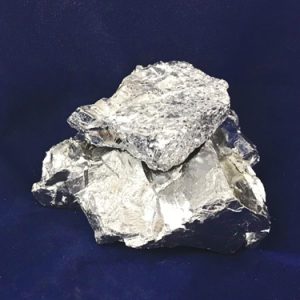

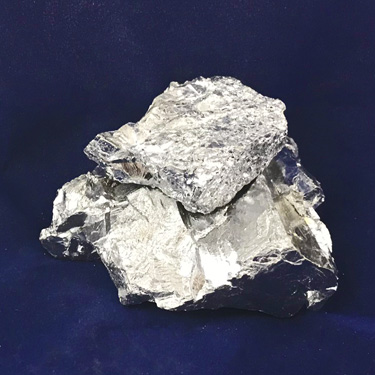

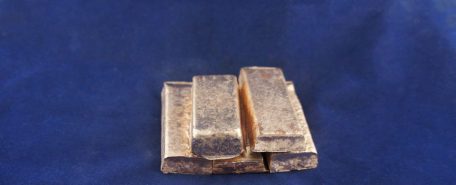

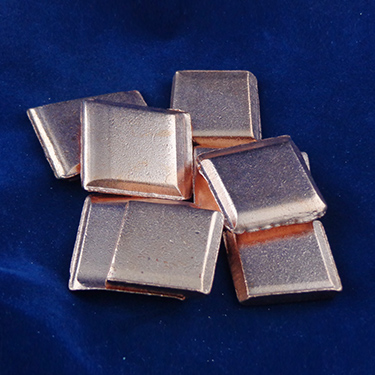

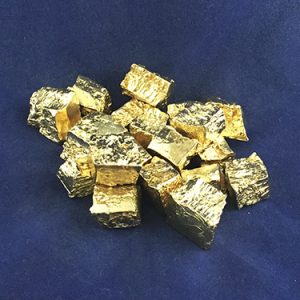

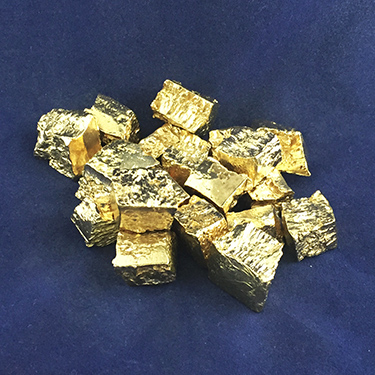

A Beryllium containing copper base master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts. Forms: - Approx. 1" Pcs.

- 1/2" and Down Shot

- Slabs

Belmont Product Code 4962 Nominal Composition: - 96% Cu

- 4% Be

$40.40

-

Lithium has the advantage of being able to combine with both oxygen and hydrogen. Used on its own, Lithium will be more of a deoxidizer. Used in a “duplex treatment”, deoxidizing first, then Lithium can be considered a degasifier now available to be a scavenger for hydrogen and other unwanted gasses. Forms: - 1 Lb. Pcs. 1" X 1" x 4"

- 3-4 Oz. Polished Pieces

- 1" x 6" x 12" Slabs

Belmont Product Code 4981 Nominal Composition: - 98% Cu

- 2% Li

$31.10 – $32.20

-

This alloy offers high strength, hardness, wear resistance with excellent fluidity. This alloy is ideal for investment, sand or ceramic casting and provides excellent replication of intricate detail. Forms: - 2-5 Ingot

- 2" Cut Bars

- 1" Cut Bar

- 1/2" Polished Cubes

- 1/2" x 14 Mesh Shot

Belmont Product Code 4977 Nominal Composition: - 97.2% Cu, 2.05% Be, 0.5% Co, 0.25% Si

$29.20 – $139.50

-

$24.80

-

$24.50

-

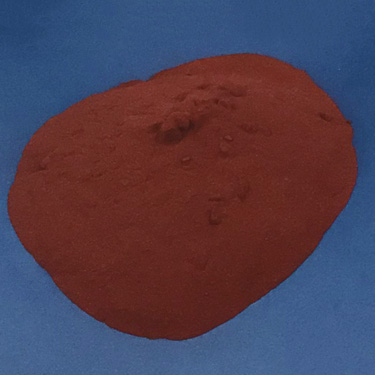

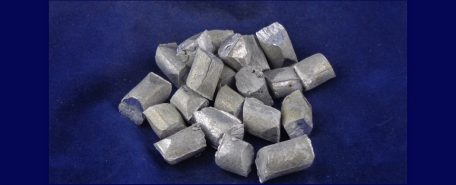

Master Alloy used in the production of Copper Alloys for a wide variety of industries. The introduction of Boron to Copper Alloys helps eliminate gas and porosity without the loss of conductivity. Forms: - 1/2" and Down Polished Shot

Belmont Product Code 49817 Nominal Composition: - 98% Cu

- 2% B

$24.40

-

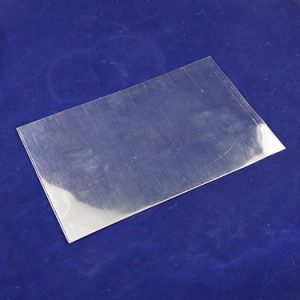

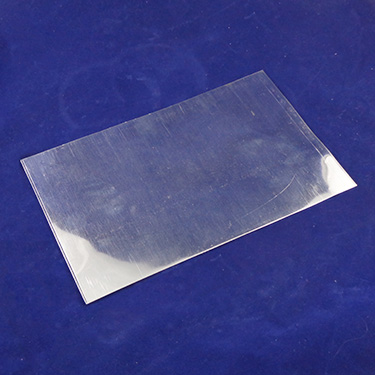

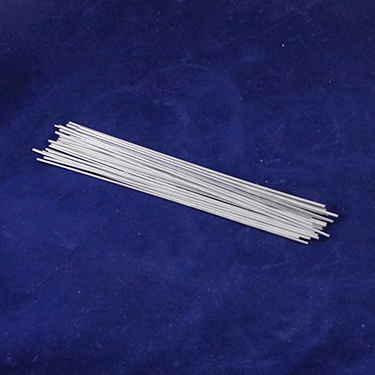

Belmont MAB ( Miter-AL-Braze ) rod is an effective and efficient joining material. Our regular version is harder and stronger than the MAB II Hi-Test that we also offer. Most users find the No. 1 Regular to be effective for general purposes. The strength of an MAB joint in many cases is as great as that of a brazed joint and this material is most commonly used for joining aluminum pieces. Forms: - 1/8" x 18" Cast Strip

- 1/8" x 12" Cast Strips

- 1/8" x 18"Cast Strips

- 3/16" x 18" Cast Strips

- 3/32" x 18" Rods

- 3/32" x 36" Cast Strips

- 3/32" x 36" Cast Strips

Belmont Product Code 8934 Nominal Composition: - Proprietary

$24.10

-

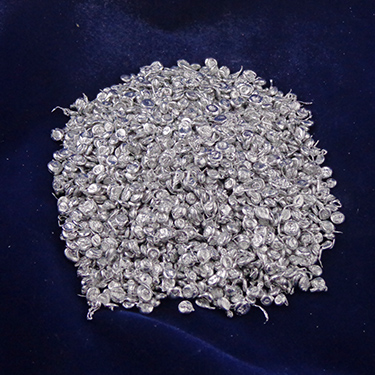

Can be considered either a deoxidizer or grain refiner. Generally, for pure copper its role would be deoxidizing but in brasses it’s more of a grain refiner. Forms: - 3/4" & Down Polished Shot

- 3/4" & Down Unpolished Shot

- 40-15 Waffle

- 4-5 Oz Pcs.

Belmont Product Code 4987 Nominal Composition: - 98% Cu

- 2% B

$23.90 – $24.40

-

$22.90

-

$21.30

-

$20.60

-

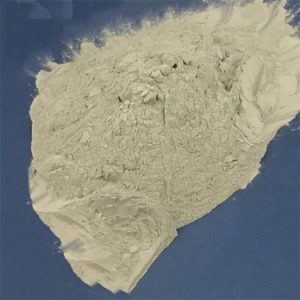

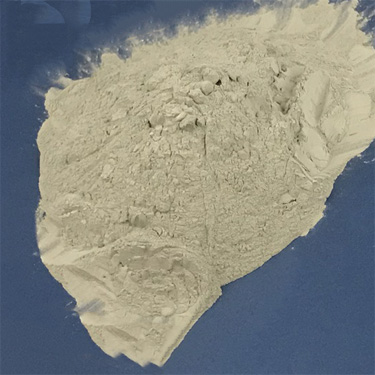

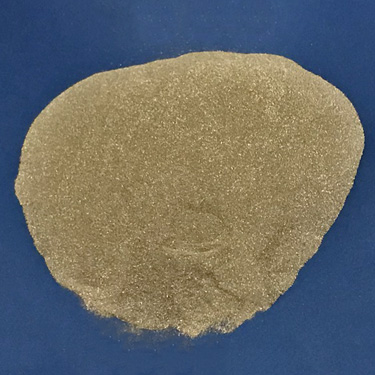

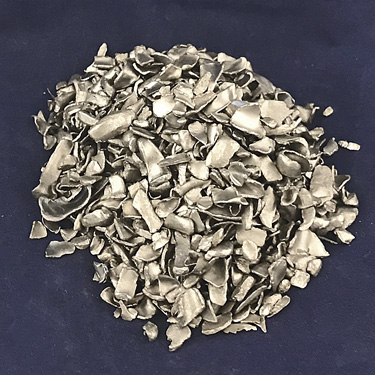

Phos Copper is the most commonly used deoxidizer. Effectively removes oxygen from molten metal with little or no reaction or dross formation. Forms: - 3 Mesh Shot

- Approx. 15 Lb. Waffle Ingots

Belmont Product Code 48514 Nominal Composition: - 85% Cu

- 15% P

$19.70

-

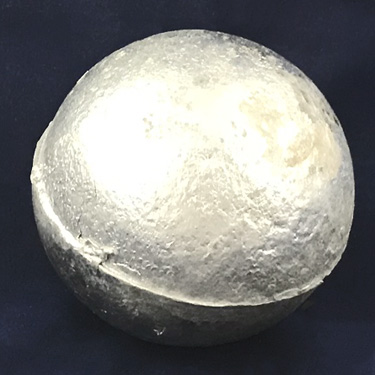

Zinc metal coatings provide better protection on Iron and Steel than any other corrosion resistant coatings. Plated SHG Zinc coatings are pure compared to hot dipped and are also thinner and more ductile, which allows them to be made brighter and more lustrous. We offer this material in 2" diameter balls that are solid and clean and do not have any flash orgates which would cause backet hang ups. Forms: - 2" Diameter Balls

Belmont Product Code 8000AG Nominal Composition: - 99.99% Zn

$17.20

-

$10.00