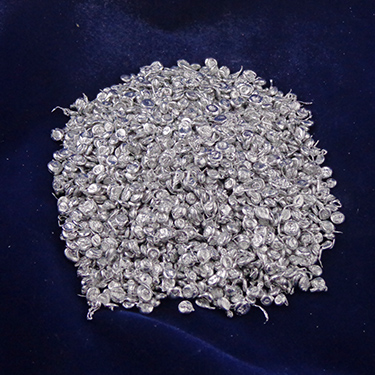

Many manufacturers require pure metals in a range of different shapes to add as additives when making products. These metals provide different properties to the products, such as hardening metals, providing corrosion resistance, or reduces oxidation. Silicon is one metal found in a wide range of industries due to its versatility and cost-effectiveness. Pure silicon…

RELATED POSTS

Pricing Trends for Minor Metals: Magnesium, Silicon, and Manganese Raw Materials

As product production goes into overdrive to meet rising consumer demand that has returned to pre-pandemic levels, minor metals are showing price increases as smelters are running at 80% to 100% capacity. Minor metals are by-products which come from base metals during the smelting process. Some of these minor metals are magnesium, silicon, and manganese…

Understanding the Various Metals Used for Plating

Are you considering plating metals? The process of metal plating is performed to improve corrosion resistance, add aesthetic appeal, enhance the metal’s hardness, reduce friction in moving pieces, increase or decrease conductivity and to improve solderability. The most common plating metals include brass, bronze, cadmium, nickel and tin, and here at Belmont Metals, we sell…

A Brief Guide to Understanding the Electroplating Process

Electroplating refers to a process used to bind a layer of one metal over the surface of another one. Electroplating changes the properties of an item’s surface, providing protection, improving its appearance, or very often, both. Besides creating a protective coating for a metal item, manufacturers also might use electroplating to increase its thickness or…

Cobalt Applications: Increasing Demand for This Metal Impacting Availability

Cobalt has seen rapid market growth for the past few decades. It has wide ranging uses in a number of applications as prices have skyrocketed for this metal since 2017. With the increase in demand, and its use in certain specific applications, manufacturers have to consider whether they will have enough supplies for their current…

Manganese Availability and Applications: It’s Growing Importance

When it comes to using certain metals in manufacturing processes, the pure state of the element cannot be used due to having negative properties. In the case of manganese, this metal is too brittle to be used on its own. However, when it is used as an additive in other base metals such as steel,…

Zirconium: An Alloying Element with Copper Alloys

Copper alloys are widely used metals for manufacturing purposes around the world. From copper pipes, electrical wires, mechanical components and other applications, manufacturers are creating the products for companies to run their operations and for the public to improve their daily lives. This unique alloy offers excellent thermal and electrical capabilities. Other elements will also…

Commodities Pricing Update: April 2020 Prices for Metals

With the growing pandemic affecting every country around the world, the market has been thrown into chaos regarding future uncertainties of the economic landscape. Companies are closing to prevent the spread of the coronavirus to workers as employees are telecommuting. Many manufacturers have cut back on their production lines or are switching over their lines…

Electroplating Advantages: Using Different Coating Products to Provide Enhanced Benefits

You would be surprised just how many items in our lives have electroplating. From your car when driving to work to the jewelry worn on special occasions, commercial manufacturing processes rely on this process to protect metals, as well as plastics, by coating them with an exterior layer of metal. While the most well-known reason…

What is electroplating?

Electroplating refers to a process that adds a surface layer of metal to another type of metal. It’s typically used to prevent corrosion and rust and to extend the useful life of the metal underneath the electroplated metal. Of course, it’s also used to make gold and silver plated jewelry and knickknacks and to give…

Global Manganese Market: How Chinese Tariffs Affect This Commodity

Many base metals need to be alloyed with other materials to help improve their mechanical and structural properties. In addition, metals may be added into the melt to remove impurities. Manganese is one such material that lends a range of positive characteristics and aspects when combined with other base metals and alloys. It is mainly…

Oversupply and Slow Demand Creating Fluctuating Cobalt Prices into 2019

When it comes to tools, superalloys, magnets and batteries, cobalt is a key material used in manufacturing products we need in our daily lives. Purchasing this metal at an acceptable price and answering consumer demand can influence a manufacturer’s operations now and in the future. When looking at the price market, there has been drastic…

Electroplating with Tin Anodes: Uses and Examples

Machinery used in manufacturing applications can consist of a range of metals and alloys that provide strength, electrical and thermal conductivity, durability, workability and other characteristics. However, the metal part itself could be detrimentally impacted by the environment and the working application itself. In other instances, the metal part could create problems if it comes…

Antimony: Possessing Durability and Versatility When Alloyed with Other Metals

Semiconductors, machine bearings, and utensils are all made from varying amounts of metal alloys. Yet these items also possess one common factor: antimony. Antimony is a semi-metal element that comes in both a powdered form as well as a hard and brittle metal. Possessing a silvery, blush white appearance, this element is highly desired when…

Benefits of Minor Metals for Your Manufacturing Business

Using minor metals from Belmont Metals in Brooklyn, NY can greatly improve your manufacturing process. These metals are often added to master alloys to improve certain desirable properties. For example, electrolytic manganese is often added to steel, aluminum and copper master alloys in order to increase the metal’s ferromagnetic properties. Types of Minor Metals and…

Beyond base metals

Minor metals are major players in high-tech innovation Typically the word “minor” refers to things of lesser importance, size or degree. Minor metals, however, are far from inferior—they are major players in a wide range of specialty, high-tech industries and used to create alloys with desirable mechanical properties, including deformability and corrosion resistance. Minor metals…