When we think about aluminum, we most often associate this metal to the flexible foil used for everyday cooking. Yet this alloy can be used in applications where strength, corrosion resistance and weldability are required. The construction industry often uses aluminum alloys as beams, metal sheathing, and as scaffolding. This metal can also be used…

with Beryllium, Boron, Boron-Titanium, Chromium, Copper, Iron, Lithium , Magnesium, Manganese, Nickel, Silicon, Titanium, Zinc

Belmont Aluminum Master Alloys are alloying elements manufactured from Aluminum and are combined with a high percentages of one or more elements. Our alloys enable casting houses and ingot manufacturers to overcome problems associated with alloying that they may experience when working with molten metals.

Master Alloys are commonly used as additives in the manufacture of other alloys or as deoxidants, degasifiers, desulphurizing agents or of similar use in the metallurgy of non ferrous metals. A Master Alloy can be referred to as a “hardener”, “grain refiner” or “modifier”, depending on the application

There are several reasons for adding a Master Alloys to a melt, the main one being selective composition adjustment. They are used to modify the composition of the molten metal, allowing you to achieve a desired chemical specification. A second important application is for specific performance requirements. Master Alloys have the ability to change the micro-structure of a metal during casting and solidification in order to change its properties. Properties that can be modified include: castability, surface finish, electrical conductivity, mechanical strength or ductility.

The use of a Master Alloy instead of a pure metal can be for economical reasons, since certain elements will have a poor yield or create high losses when melted in pure form. Technical issues may also prevent the pure metals from dissolving completely or the required furnace temperature is too high for a basic casting operations equipment. Our Master Alloys provide the solution by dissolving quicker at lower temperatures while saving valuable time and energy.

Applications

Used to enhance properties of Aluminum Alloys to increase Fluidity, Hardness, & Castability

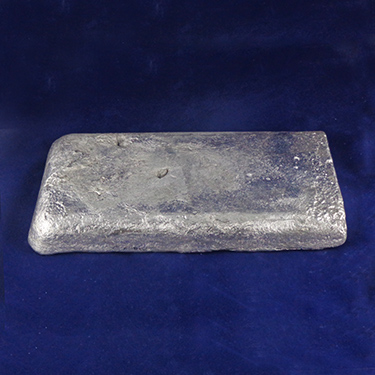

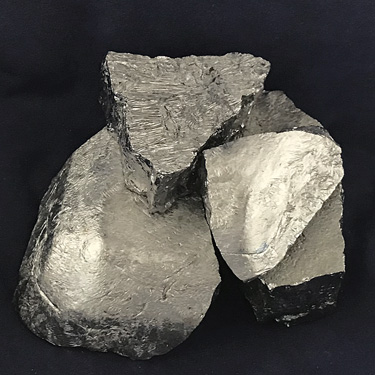

Forms

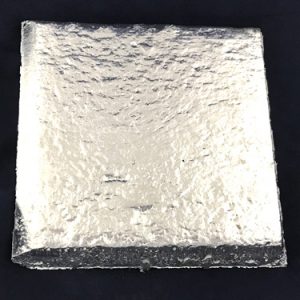

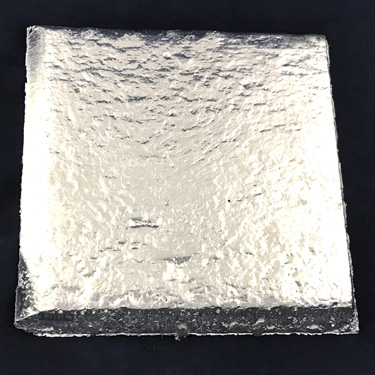

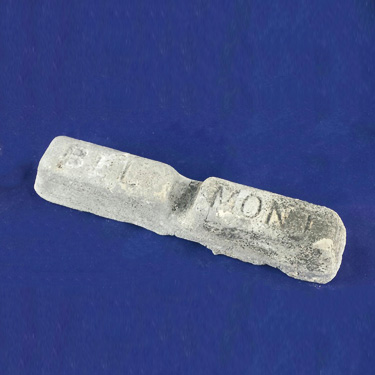

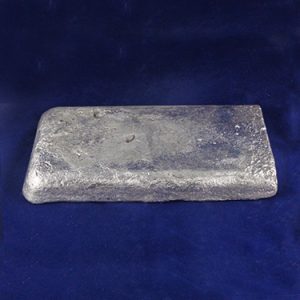

Slab, Waffle, Ingot, Lumps

Read More

Showing all 21 results

Featured products

-

Silicon ranks second to Copper in the importance in Aluminum Casting Alloys. Silicon reduces the melting temperature without causing brittleness, increases fluidity, and reduces hot tearing. This improves overall casting characteristics allowing for thinner and more intricate castings to be made. Silicon additions can reduce the amount casting shrinkage and in general Aluminum-Silicon Alloys have been resistance to corrosion. Forms: - 16-17 Waffle

- 30-60 Mesh Granular

Belmont Product Code 1503 Nominal Composition: - 50% Al

- 50% Si

-

-

-

Lithium added to Alloys containing Magnesium help prevent dross formation. Forms: - 1" x 6" X 12" Slabs

- 2-2 Ingot

Belmont Product Code 19515 Nominal Composition: - 95% Al

- 5% Li

-

Chromium will improve strength without adversely affecting ductility. Forms: - 1" x 6" x 12" Slabs

Belmont Product Code 18012 Nominal Composition: - 80% Al

- 20% Cr

-

-

Titanium is a grain refiner for Aluminum and improves mechanical properties. Forms: - 1" x 1" x 3" Sheared Pieces

Belmont Product Code 19512 Nominal Composition: - 94% Al

- 6% Ti

-

-

The presence of Iron in Aluminum aides in the decrease of hot tears, improves tensile, yield, and hardness and preserves strength at elevated temperature. Forms: - 16-20 Waffle

Belmont Product Code 19013 Nominal Composition: - 90% Al

- 10% Fe

-

-

Manganese added to Aluminum increases strength and hardness. It's beneficial in regards to corrosion resistance. Manganese is a grain refiner foir Aluminum. When Manganese is balanced with Iron it can change Iron rich needles to plates increasing ductility. Forms: - 5" x 1/2" Broken Slab

Belmont Product Code 1402 Nominal Composition: - 40% Al

- 60% Mn

RELATED POSTS

Alloy Properties: Altering the Composition of Metals

For specific applications, you know that using alloys will be the best choice when you are looking for metals that will provide special properties such as strength, thermal conductivity or corrosion resistance. Yet you may be wondering why you can’t simply use the metal it its original form. For example, why can’t you get the…

Magnesium Elements: Providing Positive Benefits to Copper and Aluminum Alloys

Alloys on their own can offer a range of mechanical and structural benefits for manufacturers and other industries. Yet your application may require the alloy to have increased strength, workability, or ductility for the particular application. Magnesium is one of many chemical elements that becomes added to other alloys such as copper and aluminum to…

Silicon: Increasing the Properties of Aluminum and Copper Alloys

Copper and aluminum are used in a range of applications around the world. You can find aluminum as beverage cans, metal building sheets and storage tanks. Copper is often found in environments that are electrically conducive, as you may see it as wiring. You can also find copper in electronics and used as brass or…

Cold Working Aluminum Alloys

When considering working and manufacturing with metals, particularly with aluminum, the first thoughts are centered on the heating process with hot furnaces where the metal is heated to extremely high temperatures and then wrought or cast into form. However, there is another type of process to strengthen the metal that involves adding other alloys to…

Grain Refinement of Aluminium Alloys

Look around you. You live in a world that contains raw materials that are formed and produced into the products you use and the homes you live in. One of the most widely available metals in the world is aluminum. It is the second most abundant element in the environment as we use it in…

Custom creations

Aluminum master alloys help metallurgists fine-tune alloys to create materials that are stronger, lighter, and more easily processed Aluminum is the most abundant metallic element in the Earth’s crust—it’s even more common than Iron. In its pure form, though, it’s soft and malleable. It needs to be alloyed with other elements, including Iron, Zinc, Silicon,…

Beyond base metals

Minor metals are major players in high-tech innovation Typically the word “minor” refers to things of lesser importance, size or degree. Minor metals, however, are far from inferior—they are major players in a wide range of specialty, high-tech industries and used to create alloys with desirable mechanical properties, including deformability and corrosion resistance. Minor metals…

The right metal for the job

Custom alloys can help streamline production Although custom alloys often are associated with new and advanced applications, they also can solve real-world production problems. For more than a century, Belmont Metals, based in Brooklyn, New York, has been working collaboratively with its customers to create materials that can improve their manufacturing processes. Coming up with…

Controlling composition using Master Alloys

Create materials that meet specific needs by adding master alloys to the mix It’s important to choose the right materials for a job. Using inferior or unsuitable materials can make completing a project more difficult or even derail it entirely. In the metals industry, combinations of metals, called alloys, are generated to meet the specific…