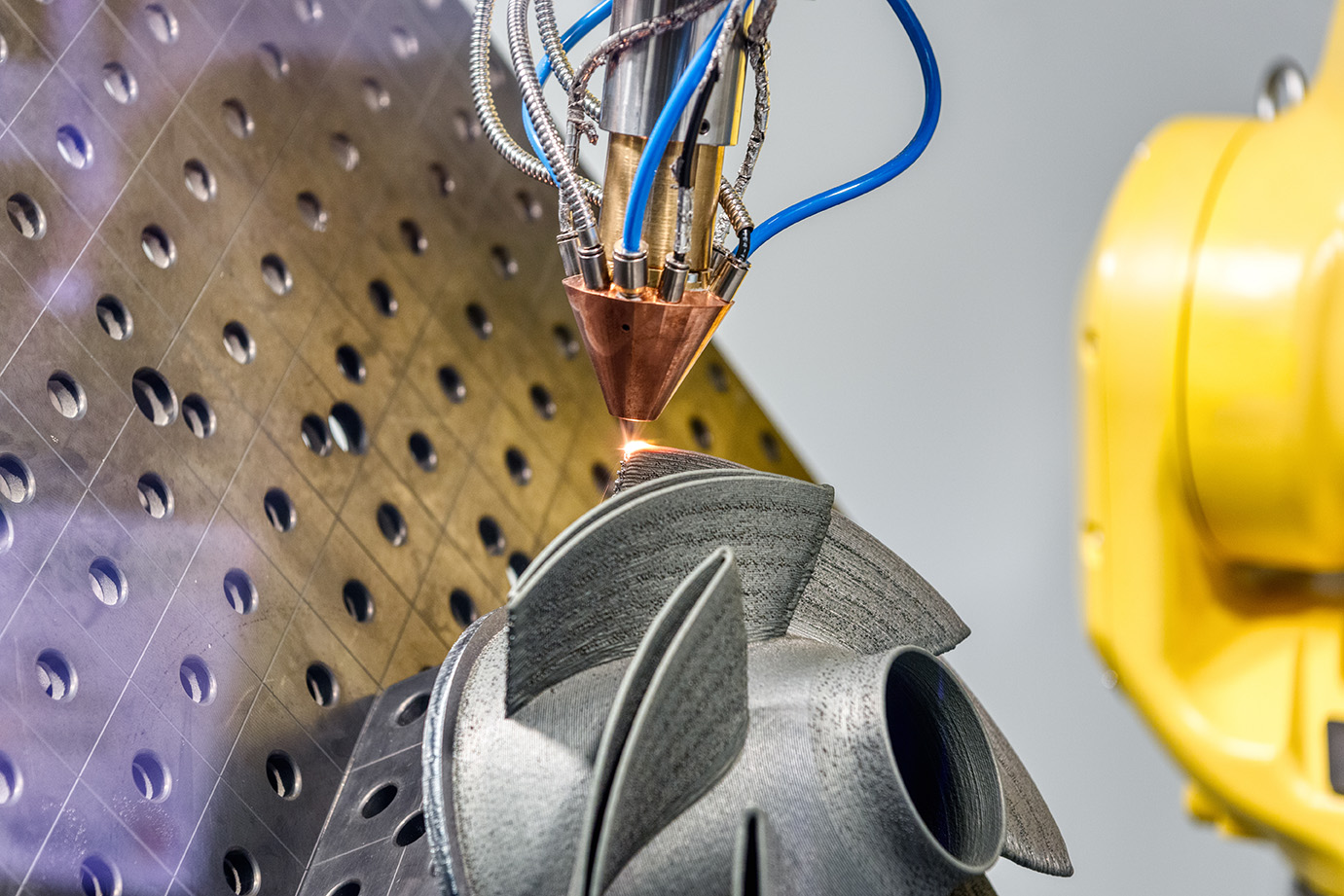

How to Reduce Oxidation for Copper and Aluminum Alloys

When aluminum comes into contact with air, it oxidizes and creates a thin layer of aluminum oxide. Although copper offers a higher level of oxidation resistance, it still reacts with oxygen. The reaction creates copper oxide, which produces a telltale blue-green patina on the metal. In some cases, the oxide layer weakens the underlying metal,…